-

Posts

27,140 -

Joined

-

Last visited

-

Days Won

263

Content Type

Profiles

Forums

Events

Everything posted by n_maher

-

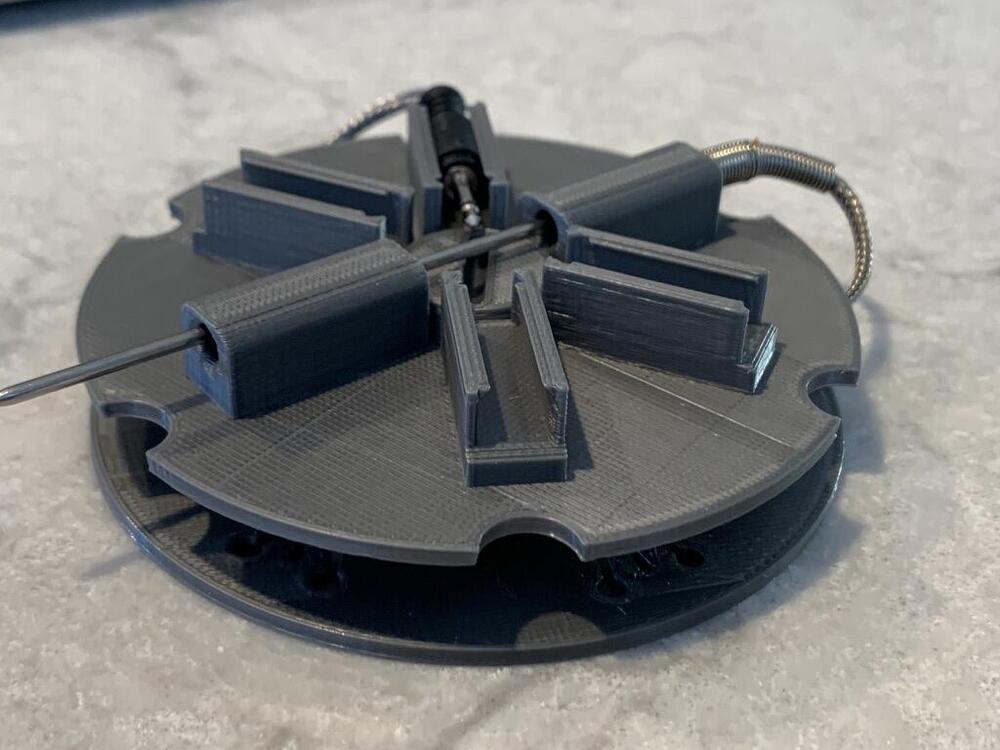

I don't think I posted about this anywhere else but have been meaning to. I got back to some non-wood, non-electronics making again during the great COVID family crisis of 2022 and addressed one of my lingering frustrations with my pellet smoker, namely the storage of temperature probes when not in use. I had gotten frustrated enough that I was about to pull the trigger on some not-horribly priced Fireboard branded probe storage thingies when I figured that some glorious nerd had probably put something up on Thingiverse and that I should check there first. Turns out I was right. I tried a couple examples and found pay dirt on my second go.

-

The Official Head-Case Photography Thread.

n_maher replied to Knuckledragger's topic in Miscellaneous

With a body that old my interest would be driven entirely by the quality of the glass. As others have mentioned, those will be the pieces that carry on with you and perhaps steer you to a replacement body some day. If you post up what they actually are some with more knowledge than me can probably better gauge if this is a good deal or not. Otherwise I've got nothing that hasn't already been said. For casual shooting it's probably great but the real question is, are you going to lug it around and actually use it. That's what keeps me from reinvesting in either a mirrorless or DSLR setup. My current, similarly outdated setup has been in the closet for two years. For casual imagery my phone is infinitely more available and used carefully, can produce solid results. It lacks range, and that's a gap that glass can close and for sports/moving-subjects there's no question a proper camera will be easier to use and get better results. -

I do when it doesn't show up. Winter is not so long here, even back in the day before it barely existed. By the end of the week it's supposed to be back in the 40s and raining, that I don't miss.

-

Yup, it’s proper winter out. We seem to be getting the lower of projected snow fall totals which is ok but it’s 12F with wind and not a good time to be outside.

-

The snowmageddon has commenced here in southern NH. It started around 7am and has picked up significantly in the last hour. Winds are steady and not insane, here's to hoping they stay that way and the power stays on. Brisket production has already been delayed one day to allow weather to clear and avoid an interrupted cook. Bear in mind that the yard was 100% bare of snow yesterday.

-

Damn @Voltron, I'm hungry. Fax is on...

-

The restocking fee is complete BS, Greg. Here's to hoping PP sees the light of day.

-

If your transformer is heating up that quickly you've got a short somewhere, or something wired seriously wrong. I'd recommend posting up some pictures of the entire build if you can folks can look for at least the obvious faults. I don't know the project well enough to start talking specifics but i don't think and under-rated trafo would behave that badly, that quickly, unless it was way undersized.

-

Not sure what you think the point of changing the thread title was, but congrats on earning a 1-day timeout.

-

It's been somewhat bananas here, with temps either being way above normal with precipitation (earlier in the week 45 and rainy) and now a run of single-digit frigid cold with wind chills deep into the negatives digits. There's virtually no snow left at this point and the skiing is shit from all the rain so it's pretty hard to enjoy winter when it's like that.

-

I think you misunderstand slander. I think you misunderstand this forum. I think you should hit pause, relax, and try posting less.

-

Try this bit of magic.

-

Happy birthday, Mike!

-

RIP, Mr. McGee. https://www.bbc.com/news/world-us-canada-60019483

-

We're forecast to only get rain tonight/tomorrow which is a huge bummer and quiet the departure from the bitter cold of the last several days.

-

A milling machine is what would probably be good for cutting 1/4" aluminum.

-

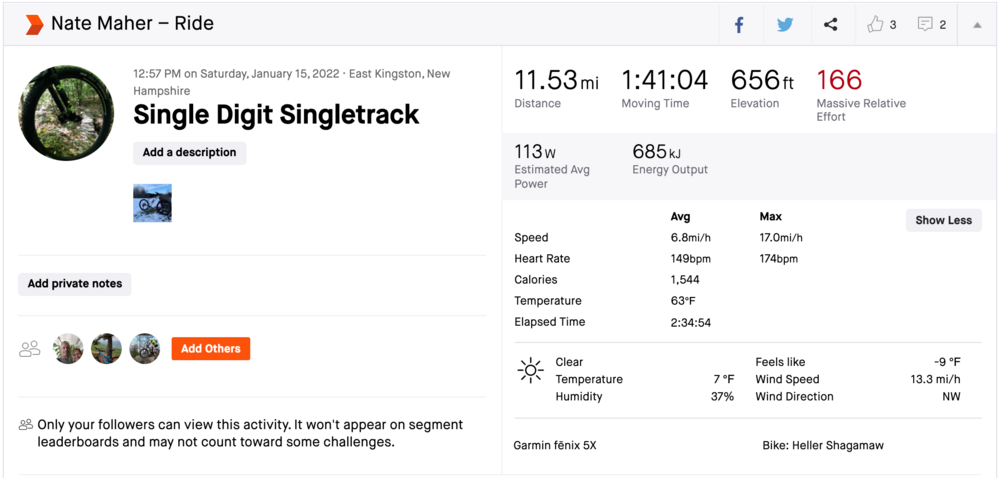

The winter rig, built last year as a COVID project before it became impossible to find reasonably priced used bike parts, performed very well. Especially once I realized I was running the tire pressures way too high.

-

File this under, If you want maximum stupid I am the guy. Feels like -9F was accurate, toes were very cold, otherwise I was appropriately dressed.

-

Happy Birthday, Gman!

-

That sucks, Greg, and agreed that there's a range of settings on the grinder for a reason and that if it's not even able to function within those settings out of the box, something isn't right. It's pretty absurd of them threaten a restocking fee for a device that isn't working and I'd fight that thru my CC if I were you if they go down that route. I also wouldn't be particularly shy about leaving a detailed review if needed. For now, I'd just move onto the next vendor and grinder and put it behind you as much as possible. Life is too short to be mad at coffee.

-

^^ That sounds spectacularly shitty, Greg.

-

It's currently 0F here, and didn't get above 6F today, with windchills way into the negatives. The dog pretty much told me to fuck off while walking him this morning.

-

I think Bob was funnier than he often got credit for because a lot of his work was on the softer side of things. In the end what is most terrible to me (so far anyway) is him passing unexpectedly at 65. My comment to my wife was that I’m closer to that age than I am 21 and 21 doesn’t feel all that long ago.

-

Went a little crazy today and in the morning while I had time I candied some chopped pecans for use later in the day. When I finally had more time, after making dinner, I made maple frosted pecan scones.