crappyjones123

Returning Member-

Posts

3,754 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Events

Everything posted by crappyjones123

-

so fucking happy right now even with the t amp at 15% they can fill up my office beautifully. was skeptical about the 1.8 watt decware amp but all reservations have been removed. yes i know the drivers are mounted sideways but theres a brace directly behind the driver and thats the only way the driver would go in without damage to driver posts. i did about 15% of the work in building them. rather happy with the outcome. the guys who built them did a beautiful job. pictures dont really shop the texture all that well.

-

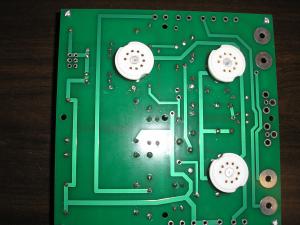

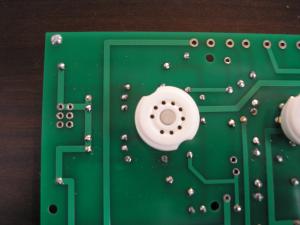

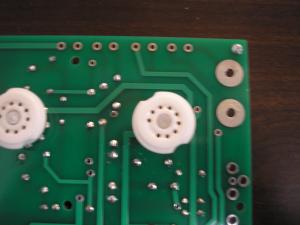

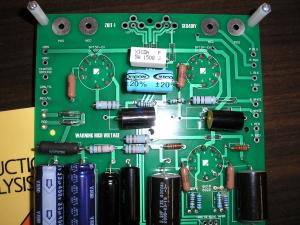

Received this kit a few weeks ago and after working with it on and off i have the board populated. before i actually start the casework, if anyone has any comments/concerns/suggestions regarding just the soldering portion or anything else for that matter please feel free to post them. i have very unsteady hands so some of the pictures might be out of focus. my apologies. anyhow here are some pictures. the output transformers are allegedly custom wound for decware. thats about all i know about them. no clue as to the output impedance and what not. el cheapo el 84's from leeds radio in nyc. didnt want to use any expensive stuff while the amp is still in the testing stages. got an assortment of 5 6922's from ebay.

-

finally i get to hear the hd800s thanks gene.

-

HOLY MOTHER OF ALL THINGS THAT ARE HOLY OR EVEN REMOTELY HOLY. i want that horn sub so bad steve build me one?

-

wonder if there is any way i could put them in my 11x9x8 room. suggestions are welcome guys.... god do they look sexy.

-

the meet is smack in the middle of finals week for me so no friday night festivities for me.

-

this meet is getting bigger and bigger...canjam and a half?

-

i have 2 exams on monday and 1 on friday so cant offer rides to or from the airport. will make a short appearance at the meet though

-

happy bday peter

-

F1 + some nice single driver speakers...tasty

-

last weekend i slept on the tiled floor of my office...initially it was terrible but when i woke up 3 hours later, it was the best sleep i had ever had. start sleeping on the floor people. good for your back. (bad for the hips but who uses those things anyways ) i live locally so matt/brent/colin can have my usual floorspace. i might call in a favor at canjam if my cousin is not in town.

-

happy birthday vicki! hope you have a great day.

-

looking forward to meeting all the new people ill come by for a little even if i got exams looming around.

-

looks like the speaker building will start this weekend. instead of going weak i am going all out and going straight to the top with the fonken design. http://homepage.mac.com/tlinespeakers/FAL/box-plans/Fonken-1v01a-map.pdf looking forward to listening to some god damn music again.

-

i meant to say that its very easy to get addicted to meets. after a while its no longer about auditioning gear and what not. it becomes about hanging out with people you havent seen in a while and then listening to a song once in a while.

-

last meet i went to (plantation meet) i listened to mike's tt and that was about it. didnt really listen to much else. mostly hung out and talked with people.

-

mike would you mind if i invited 2 people? one owns a carpentry shop in boca raton and the other runs a fabric business. both are avid music listeners but i dont think they know much about headphones (the good ones at least). both are great guys. i had a 4 hour conversation about speaker designs with them today and i was supposed to go there just to ask for prices.

-

work im building a speaker amp right now. will most probably have it done by the meet. going to start building cabinets for the speaker on oct 29th. so should have both the speaker and the amp done by then. might bring it by if anyone wants to look or listen. how is the restaurant doing?

-

might have exams around then. if not then i will show up.

-

if you are set on a full range then the fostex 127e's are usually suggested over the 167e's for near field usage. there are far too many designs based around the 127e and planet10-hifi has a shitload of them. the fonkens take the top honors for all categories going lower than 40hz (a usable 40hz). its an annoying build though because it has lots of little pieces so local shops tend to charge a lot for the time. however there are quite a few simple designs on there as well that you can email to local furniture stores and see what they can build it for you for. the lowest cost for a bass reflex cabinet (not the optimal cabinet for the 127e was some $150 in construction (including materials) + cost of drivers. which is a very nice low figure. for a $100 more you could get the same speaker from tekton so it really depends on if you dont mind spending the extra cash. on diyaudio, for a 12x13 room, the fonkens were suggested over most other larger boxes given their ease of integration into the room. bigger cabinets will result in bass issues (too much or too little) and placement becomes a factor as well. even the metronomes i heard over at carl's house could very easily fill that 12x15 room and sound amazing. depends on what you are going for. if you want something big and imposing, look into a BIB for the 127e driver. should go lower and easily fill up that room. i think it might just squeeze into that budget of yours. link to bibs. Bigger Is Better 'BIB' Cabinet Dimensions - ZillaSpeak link to 127e cabinets. ZillaSpeak - Speakers planet_10 hifi

-

i turned it on a few minutes ago and it stank up the office so bad people couldnt sit in there. the guy that i got it from said that it was one of the better pieces that he had tested so he gave it to me.

-

just got this for free from the good folks upstairs. nothing beats a free soldering iron (the one i have a cheap one from home depot) but is it any good? has a nice little slider for temperature control. cant find too much info on it online so i thought i would ask. the guy who runs the electrical engineering labs is cleaning house so is giving away a crapload of stuff (transformers/old drivers/test equipment/anything under the sun). i already called dibs on anything audio and surprisingly he hasnt had any requests for the stuff i put my name down for so should be nice. he used to work for bendix back in the day and has some 600 tubes in pristine condition he is trying to get rid of. dont know if ill be able to get those but if i do, ill pass them around for the cost of shipping to anyone who wants specific ones.

-

aura, odyssey also makes a pair of monitors that hold fairly high resale value on audiocircle. and im sure klaus has some sort of return in 30 days for money back deal as well. might want to consider those as well. the floorstanders have a cult following on that site. dont know much about the monitors but given his reputation i cant imagine them sucking. luvdunhill, maybe its because its 7am, but i dont know what you mean by your post =/ NEED MOAR SLEEP!

-

wonder if we could get a head case discount from eric hehe. that would be pretty nice. any chance you were looking at the 167e luvdunhill?

-

i just lost a giant post...freaking lame ass network outage. summary is as follows. 1. look at diy options. full range/wide range + tweeter. 2. find a local woodworker to build the cabinets. 3. look at tekton audio. they have actually turned out to be roughly $150 cheaper than all the quotes i received from local shops. the prices are VERY reasonable. maybe a $150-$200 profit besides the cost of parts. im talking with the guy regarding a wide range fostex driver + some super tweeter that he has designed. will pull the trigger next fridays paycheck. 4. going for high efficiency drivers helps with the amp question. no need for any big wattage amps. just a few clean watts pushes these things to ear splitting levels. im getting them for my office for near field listening. dont think ill need more than a watt. 3 watts pushed the 127e drivers to very uncomfortable volumes for me.