-

Posts

6,613 -

Joined

-

Last visited

-

Days Won

150

Content Type

Profiles

Forums

Events

Everything posted by naamanf

-

Wouldn't surprise me if they start selling them soon. They already have Traegers.

-

Threw together a tool board in VCarve. In hindsight I could have done a better job with the space but it works for now.

-

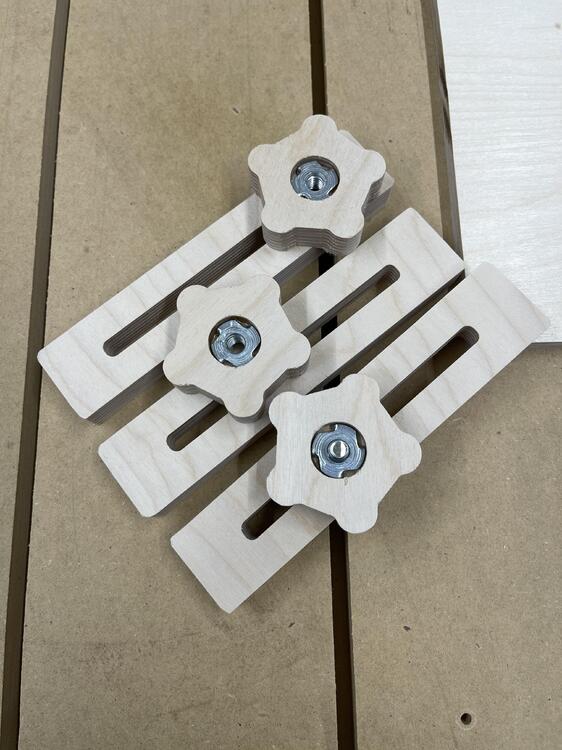

Steve knows my hobbies well 😂 Made some hold downs. Seems a compression bit is key when cutting plywood.

-

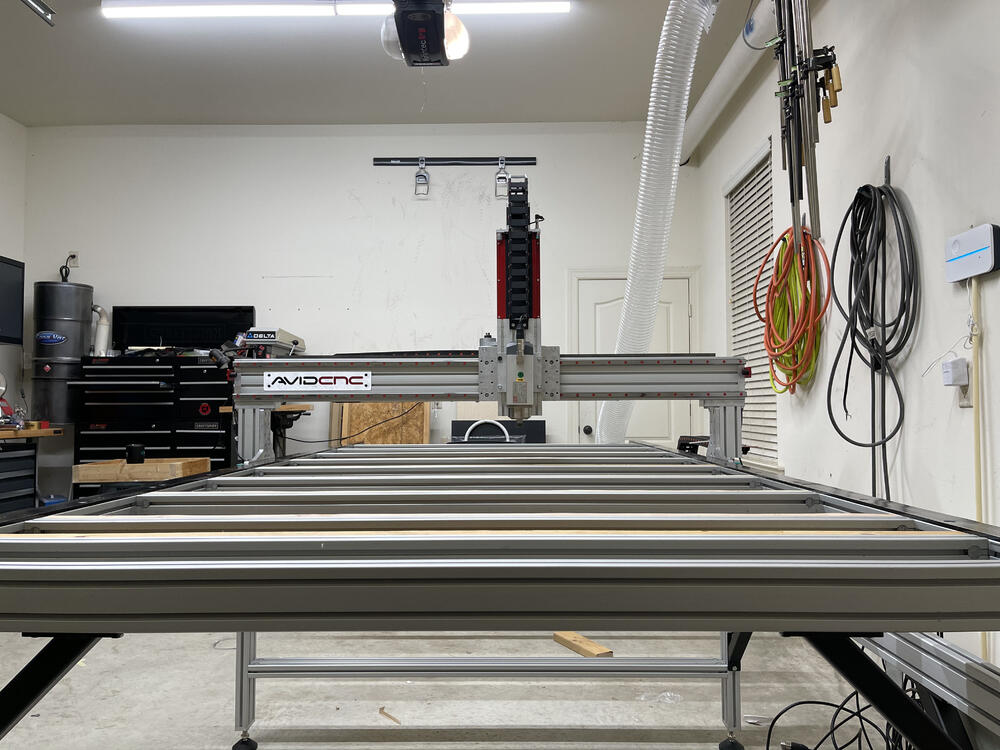

Put on and cut a spoilboard with T hold down tracks. I’m seeing that work holding is a large challenge. For some reason I see a vacuum pump in my future. And a ATC, pulling collets off and on is lame.

-

Easy for my drilling robot, just need exact dimensions.

-

Drilled four holes. IMG_3596.MOV

-

-

Having a large cabinet humidor has been my want list for a long time. I’ve actually been thinking about making one for a while. Local large commercial lumber supplier actually stocks the Spanish cedar so getting material shouldn’t be that hard to make it. I just need to step up my design game.

-

They are a lot cheaper than new fingers.

-

It keeps the material pressed down on the table and the wheels are angled to keep it pressed against the fence. Basically does the same thing feather boards do, helps make straight cuts and adds some safety against kickback.

-

Put these stock guides on today and cut some 15’ pieces of ash to make stiles and rails for cabinet doors. Worked pretty well, real test will be ripping larger sheets.

-

I’ve been happy with the Freud Industrial blades I’ve bought.

-

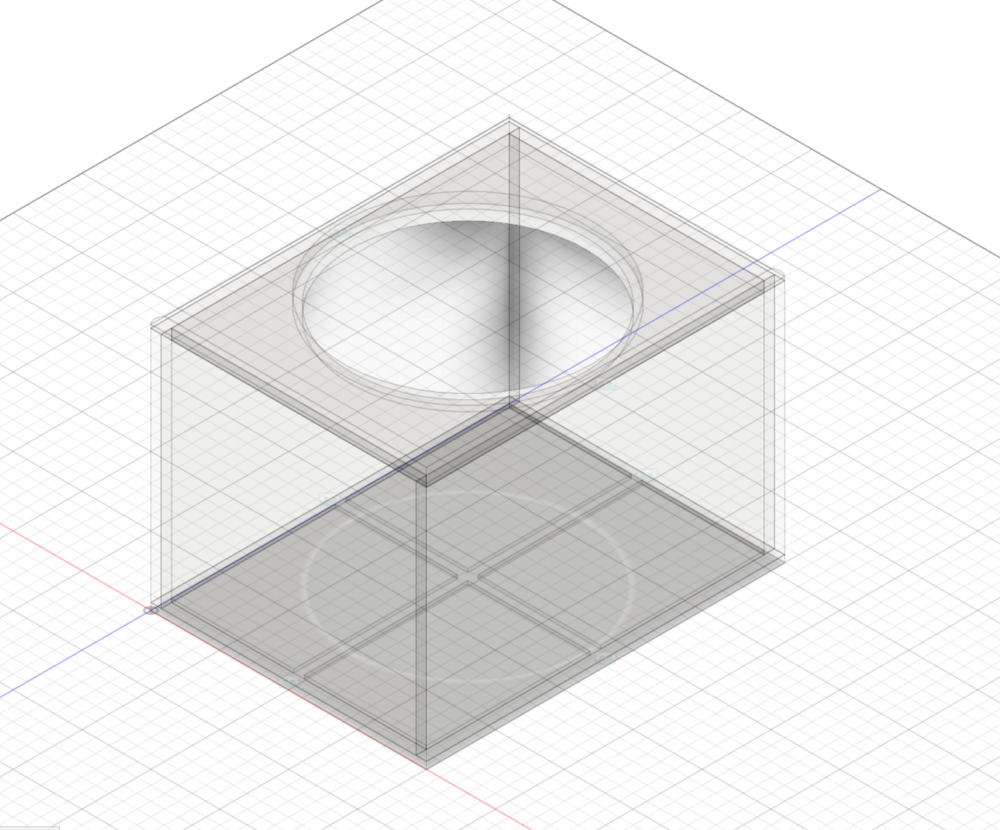

The baffle is two separate pieces, so it all can be done single sided. I still need to draw up the internal supports, but I do have the dados in the base where they will fit. Did it as a exercise to make something simple in Fusion that I could actually use someday. Who doesn't need more home theater subwoofers?

-

Ice Ice baby. Way cooler than my box 😂

-

I think that's somewhere around lesson 224. I'm on 2.

-

I present to you...a box. But it's fully parametric. Now I need to figure out how to do each component in CAM. Baby steps.

-

I get that. There are 1001 projects in my mind, how many actually will come out...no idea. Have you checked out the cnccookbook? Going to give it a whirl to see if it helps out or is worth while, 30 day free trial.

-

Thank you, I’m kind of also coming to the conclusion I need to learn Illistrator or Inkscape for vector creation. Like guitar, wish I would have picked some of these things up years ago.

-

I’ve already purchase VCarve Pro and have been learning to use it, seems pretty easy for most tasks. There is a post processor for my machine so it all should (hopefully) work well. I’m also working through Fusion and putting my head into the parametric modeling mindset since I know it’s probably the best thing for long term 3D design. So much to learn, so little time.

-

Send them my way! Edit:just got the call that it ships in the next two days!

-

Looking good, I'm dying over here waiting for mine to show up. Any day now, any day. What CAD/CAM are you using? I've been peeking at Chinese CO2 lasers on Ebay that work with Lightburn, way easier on the pocket book than comparable Epilog/Trotec machines.

-

I'm guessing that means you don't have a woodshop?

-

If you have some nice wood working tools, we would love to see them.

-

My opinion of the Festool stuff is they are excellent tools, but designed for little European craftsmen named things like Lars, Otto, Klaus, and Gunter. If you have the space large dedicated tools will always be easier to work with. That table/fence look pretty good, I would just verify you can put stops on that t-track. As for the lift Incra stuff is solid. I don't have much use with it but the Saw-stop I have seems pretty bullet proof.

-

Amazon also sells a couple in the $6 range. Just search 3.5mm TRS. Some of them you have to select to them choose the length.