-

Posts

6,613 -

Joined

-

Last visited

-

Days Won

150

Content Type

Profiles

Forums

Events

Everything posted by naamanf

-

Try harder, we expect better next time.

-

Agree, kosher is the way to go. Doesn’t he have a domino?

-

The Felder 510 looks to be about the right size as well and just about the same price, I’ll have to do some review digging.

-

The Hammer resaw height is a little small, but this one seems to match up nicely. Time to check out YouTube shills. https://shopscm.us/collections/featured-sales/products/formula-s-440p

-

No help here, I also need to purchase a “smaller” bandsaw in the 16-18” region. Smashed up a pinewood ply box.

-

Definitely a case where you don’t want to have any body part around the V. No matter your proclivities.

-

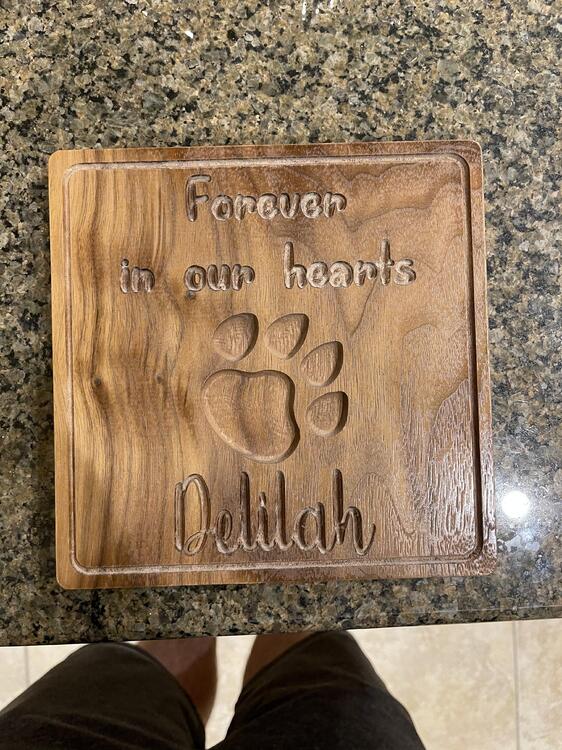

V carving is definitely the way to go, really no other way to get sharp corners. I think Fusion can generate V carve toolpaths.

-

First commissioned work. Vet hospital owner I happen to know needed a emergency gift for a client. Little boring but usable. Playing around with inlays. For a whiskey group.

-

Have to build a back box if you want to catch more with the mitre saw. They like throwing shit everywhere. Check out https://www.oneida-air.com for some smaller vortex systems.

-

If you have the space and don’t mind spending more, a vortex system would be the way to go. The Dust Right will probably work fine though, just get the canister option. Can always sell it to Brent when you step up to a CNC.

-

That’s what I did. They are not that expensive and can be used as a kayak anchor when the Red smasher becomes available.

-

-

I’m holding out for the Red smasher.

-

Correct.

-

I have the Bosch, ordered the Milwaukee and a week later told it was actually back ordered. I had the Bosch in my last router table and have no complaints.

-

Hints on maintaining / improving my Stax SRM-T1S

naamanf replied to plaurids's topic in Headphone Amplification

Needs Blackgates.- 107 replies

-

- stax

- maintenance

-

(and 1 more)

Tagged with:

-

Not until I can get sheet goods with legs.

-

I almost feeling like I’m cheating at this point. Drawing some obscure shape, loading some wood, hitting run, and poof! Magic.

-

I’m not sure if my setup can do thread milling, not sure if it’s a controller or spindle limitation. Rough draft finished. Time to get some thicker cheap wood for a full mock up.

-

Good to know that trick works with aluminum as well. As I understand it there is a bit to get thread cutting to work?

-

MDF. Not wasting wood until I have it exactly like I want it.

-

Fixed. It was there in the preview. 🤷♂️

-

Test run on what will be a Stetson and sword holder. Figured 36” would be large enough, I guess not.

-

I’m sure we could come up with some good stuff. I’m seeing that drawing the part is the smallest part of the battle. Converting it into efficient CAM and choosing the proper tools/speeds/feeds is the challenge. Good thing I’m now at the point where I have to time and resources to do what I want.

-

I got lucky and someone had them already made up for a different tool holder. If I had to do it, I would just trace, scan the trace and then do a bitmap trace in VCarve or maybe find the same tool in Inkscape.