-

Posts

6,613 -

Joined

-

Last visited

-

Days Won

150

Content Type

Profiles

Forums

Events

Everything posted by naamanf

-

They make memes.

-

-

I have the same speakers in my theater room. Great for movies, music....okay.

-

-

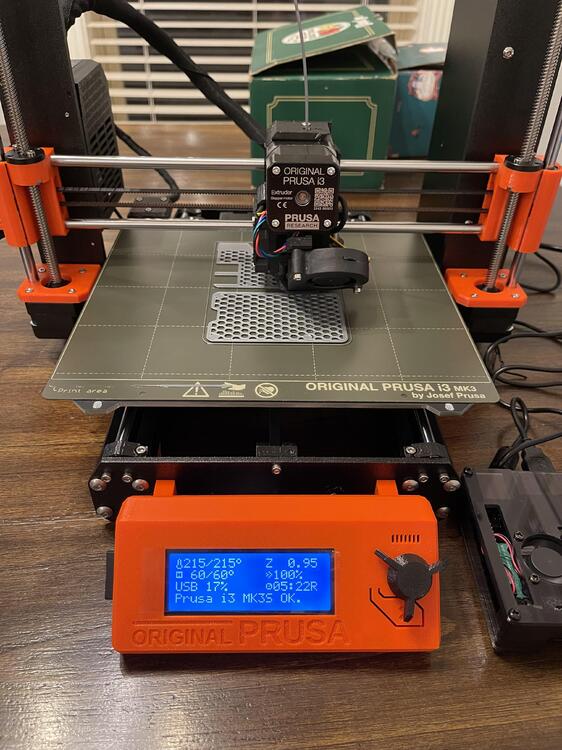

Raspberry Pi is a micro sized computer running Linux that is used as a controller for the 3D printer. Prusa is the brand of 3D printer, based out of Czech Republic.

-

Put together the Prusa. Hooked up a Pi for running Octopi and now building a case to mount the Pi directly to the Prusa.

-

-

Looking good, that’s a lot to rub on. What version did you use? I’m looking to switch to pre-cat lacquer for most of the stuff I’m doing. Applying by hand and waiting just takes to long. For those that need a new safe saw, checkout out the Felder Kappa 550 with PCS. It’s only a couple more bucks than a SawStop 🙄

-

That’s great news, though I’m a little disappointed we won’t have a full time pirate as part of the crew.

-

Cheap replica from Amazon.

-

They have not 🤔

-

-

Looking like it’s coming together nicely, Al. M&O will be making wood chips before you know it. I’m still ping ponging away.

-

Looks great! Know that we know the measurements we can always make a shim to go under the board to raise it up a bit.

-

-

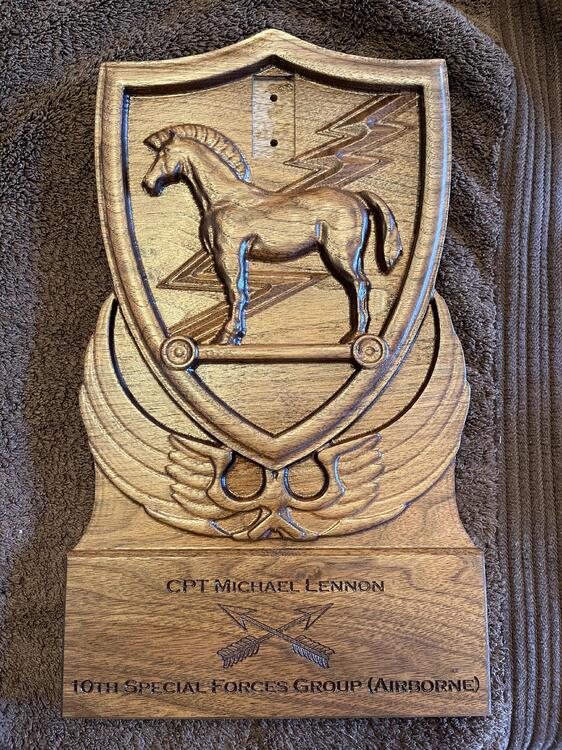

Made another one today for one of our Doctors who was SF. Going to have a holder for his green beret.

-

You can scan and convert to vectors. If you know the exact measurement you can then scale to fit.

-

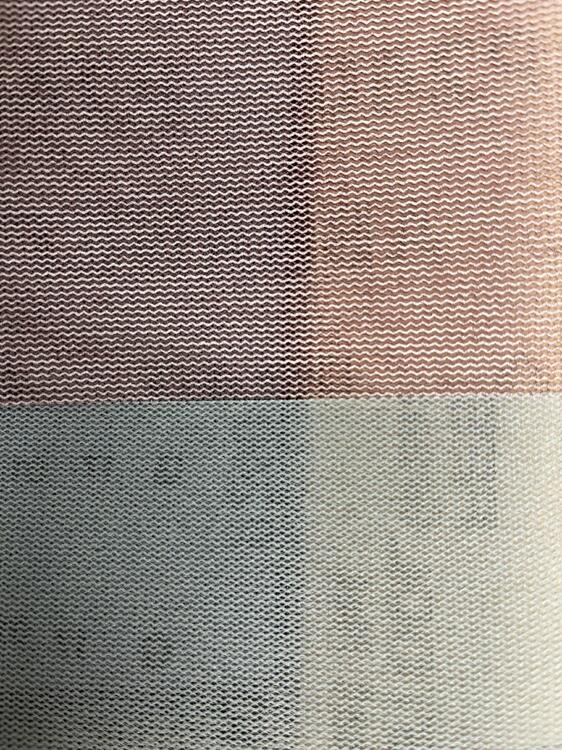

Going to give the nod to the Mirka paper, it’s a little thicker, the Festool version just doesn’t hold up as well to edges and rips easier. Thought If having to sand on edges or corners, neither is the way to go.

-

-

Just one side. Running the blade right up to the stock fence. I really need to make a resaw fence.

-

-

I’ll have to try some out. I assume any loop backed 3x5 will work. IE the Mirka paper should work fine on the Surfprep.

-

So far no issues or complaints. I don’t really have anything to compare it to besides a Makita finish sander which it is way better than. I would like to try some other brands papers, the Surfprep ones seem to wear down super quick.

-

Challenge accepted.

-

They need to do that here as well.

- 2,073 replies

-

- Golf Mafia

- M Sport

-

(and 1 more)

Tagged with: