-

Posts

6,613 -

Joined

-

Last visited

-

Days Won

150

Content Type

Profiles

Forums

Events

Everything posted by naamanf

-

Time for a mini-split. I installed a Mr. Cool in mine and so far it’s been great.

-

I would seal it all the same except for the domino holes (if you already made them) and let the TB3 seal those. Make sure you don’t use the beech dominos, they make ones specifically for outdoor/wet use.

-

If it models right but it’s going somewhere else something isn’t set right. It’s a dumb machine and does what it’s told.

-

Check where you have the origin set in V-Carve and where you have it set on the machine.

-

Saying that part of the G-code cut right then it went somewhere is shouldn’t have?

-

I think I mentioned to use cheap bits for a while. If it was a 1/4” shaft I assume you bent it? Then again your steppers might not have the power.

-

Once you get good you can walk away and hope nothing blows up.

-

Looks fabulous!

-

Try seating them better? Sometimes it takes a bit of force to get them that last little bit to fully seat.

-

Make sure it’s fully seated. Or pull it out and verify it was cut properly.

-

I’m guessing the routers are louder because they are a brushed motor. Spindles are really quite.

-

All you saw was ebony dildos in mine. What the fuck?

-

Check out Mark Lindsay’s YouTube channel. It will tech you everything you need to know. He is a little slow which is good at first but gets annoying once you know what’s going on and just want the meat. If you have any questions shoot me a message, I’m pretty good at it meow.

-

Which ever one you get make sure that you are not tied into their software. One that has a post processor available for VCarve/Fusion/Solidworks.

-

Both is the correct answer. The CNC will be limited in size but there is still a ton you can do and more importantly learn. When you finally get around to moving somewhere you can have a proper shop you will already know what you are doing on a larger machine.

-

Those look amazing! Love the pocket doors. What hardware did you use?

-

Looks great!

-

Definitely. On both counts. I had to rotate two but took about a minute each and I was back in action.

-

Did you have to rotate a segmented head to fix it?

-

I love it when you find metal in your expensive wood by running it over the jointer. That is all.

-

Looks like it was a good time. Hopefully the kick in the nuts wasn’t to bad.

-

5 minutes of ping pong work, barely long enough for a nap.

-

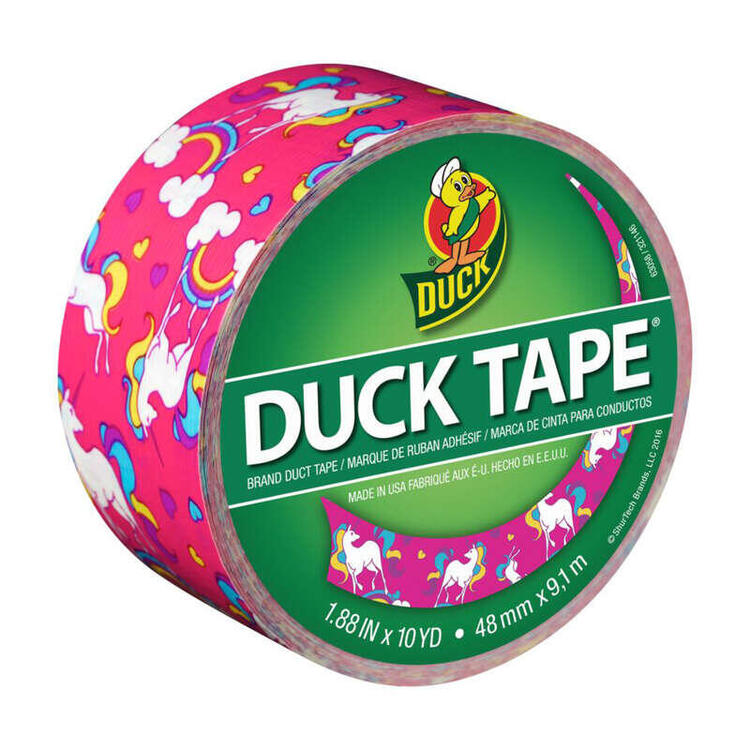

I would love to see his shop wrapped in that stuff.

-

Awesome job, Steve. Going to make for some happy zen reading. As for the complainers, be glad you don’t work in a normal job with 100+ customers walking through the door. It’s about 1-2% but they are there everyday taking up 98% of everyone’s patience.