audiostar

Returning Member-

Posts

310 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by audiostar

-

CNC metal machinists (for Stax amp cases) unite?

audiostar replied to jamesmking's topic in Do It Yourself

James, make sure you use the best possible (carbide coated) cutters and also keep in mind 1.5kw is not that much when you calculate speeds. Make sure cooling the bits and material while cutting is adequate as well. Looks like it is getting pretty hotm here, cutter is not good enough or speeds are too high. -

and now for something completely different part 3

audiostar replied to kevin gilmore's topic in Do It Yourself

Yes, couple all of them to the exact same temp. -

and now for something completely different part 3

audiostar replied to kevin gilmore's topic in Do It Yourself

JoaMat, looks nice. But don‘t the original boards have 14 heatsinked transistors instead of only 8, what‘s the change here? -

CNC metal machinists (for Stax amp cases) unite?

audiostar replied to jamesmking's topic in Do It Yourself

Now that looks like the real thing already! Congrats, James! -

and now for something completely different part 3

audiostar replied to kevin gilmore's topic in Do It Yourself

Btw, the split boards reach the goal of being able to mount vertically on the heatsinks, so there is no need for SMD 🙂 well, except for the fun of it 🙂 Just kidding. -

Group Buy - Digital Attenuator (Kevin Gilmore)

audiostar replied to sorenb's topic in Do It Yourself

Doesn't this require some changes in the software? Cause the posted software was solely developed for the 100k pot, correct me if I'm wrong. -

Group Buy - Digital Attenuator (Kevin Gilmore)

audiostar replied to sorenb's topic in Do It Yourself

Hi Kerry, this message here shows a 100k pot used in conjunction with the v2 board, the Bourns RK16812MG099. Here as well. The linear taper 10K pot was used in older v1 dual-board attenuator, that is compatible with LCDuino. migo seems to be using a v2 board, so the 100k pot looks to be about right, no? -

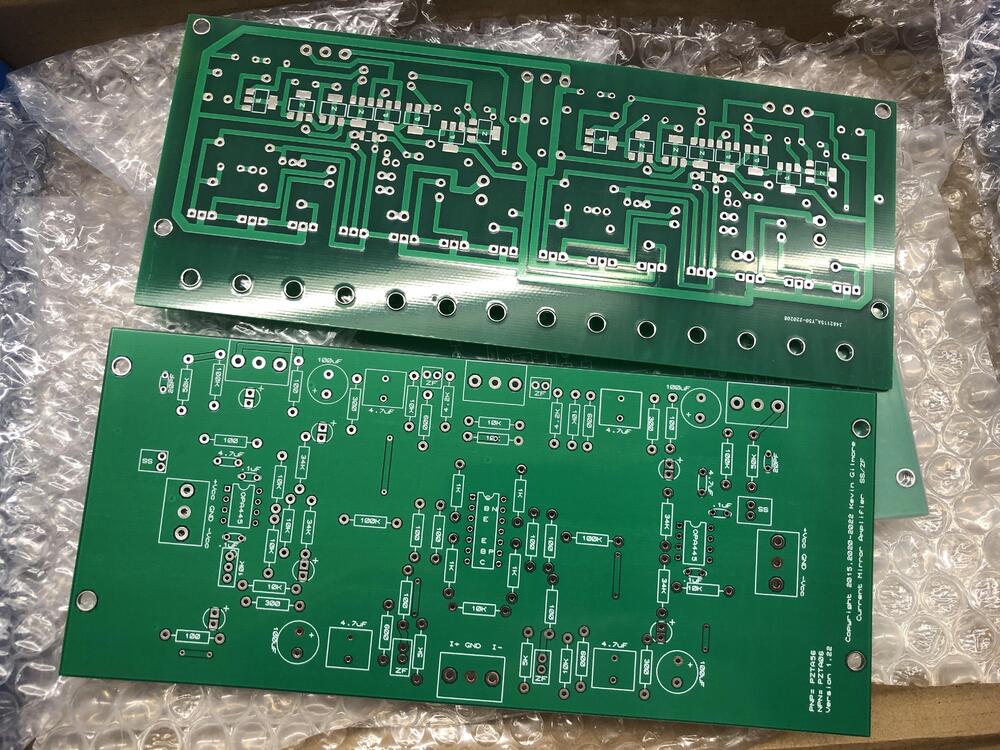

Very nice, JoaMat! I did something similar but horizontally layed out and holding two 3-pin combo-Neutrik's and two 4-pin Neutrik, directly mounted to the board, including the SS/ZF relay switching circuit as well.

-

Check out the arca-swiss style mounting plates. Very sturdy, easy to detach and there are different size plates available. Used on high-end professional telephoto lenses and heavy cameras as well. Check out Really Right Stuff in in the US, Kirk as well. Those are hard anodized parts like guns, so water shouldn't be much of an issue. The plate will fit pretty nicely the throttle from below and is easy to detach within seconds from a quick release clamp.

-

Its not about how low, but consistency within the channels, etc. @migo was testing lately the RK27 and wasn't fascinated. Don't think there is anything you should put into a Carbon below the TKD 4CP-2511 pot or the DACT/Goldpoint steppers. However, the RK27 is cheap enough, test it for yourself. Maybe it will be good enough for you. Make sure it is 10k.

-

goldenreference high voltage power supply (GRHV)

audiostar replied to Pars's topic in Do It Yourself

I have some left, PM sent -

and now for something completely different part 3

audiostar replied to kevin gilmore's topic in Do It Yourself

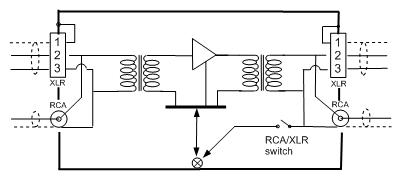

I always do loop outs on my amps in order to daisy chain to other amps, etc. So, thinking about adding RCA ins to the CFA3, which is pretty easy. The question is with the RCA outs - the following pic is from Jensen, I think, where they only connect pin3 to ground on the RCA output only and leave the XLR out floating. Is this something, that is ok with the circuitry on the CFA3? Any thoughts @kevin gilmore? Thanks! -

Yes, mechanical. It is a DPDT for two channels. Shorting pin3 to ground on the RCA out only. The XLR out is not affected by the switch.

-

Looking at something like this.

-

Any recommendation for a good quality slider switch for panel mount to be used for selecting between XLR/RCA outputs? Thanks a lot.

-

Yes, thats the simplest implementation. However one could also use a real preamp to drive the Carbon. On the other side a build in pot makes the headamp more of a standalone device. Best would be a 10k pot, 4-gang for balanced. The RK27 is certainly not on par with the RK50 (which got even more expensive today). Next would be the DACT or the Goldmund stepped attenuators (for around $450). And if you like a pot, then TKD 4CP-2511 for instance is a pretty darn good one for around $150.

-

Kerry Design mini GRHV\GRLV and JoaMat mini T2 Group Buy

audiostar replied to mwl168's topic in Do It Yourself

Lots of the parts like OPA134UA/2K5 or the voltage references LT1021DCS8-10#PBF or LT1021DCS8-7#PBF are available end of 2023. That's just insane and getting worse, like the world has run out of parts! -

Kerry Design mini GRHV\GRLV and JoaMat mini T2 Group Buy

audiostar replied to mwl168's topic in Do It Yourself

Looks like MMBT3904,215 and MMBT3906,215 from Nexperia are a good replacement for the MMBT3904 and MMBT3906 BJTs from Onsemi. -

CNC metal machinists (for Stax amp cases) unite?

audiostar replied to jamesmking's topic in Do It Yourself

Thanks, James and Kerry. I can do that additional control for the laser, no problem. Haven't researched much about mounting a laser etching head and what it would take. Looks like I am going to use that ATC spindle with a Hitachi sensorless vector VFD. And this would be a cheaper alternative. -

CNC metal machinists (for Stax amp cases) unite?

audiostar replied to jamesmking's topic in Do It Yourself

Kerry, can you recommend a laser head for etching anodized aluminium? James, which laser are you using to engrave the above? Couldn't find but maybe I missed it.. PS: soon to join the CNC machinist club with a DIY CNC and a 3hp ATC motor. -

You guys are nuts 🙂 just found this! Extremely cool work being done here!

-

Thanks, Rinat! PS: That Kester is the same that I use, really nice.

-

More pics, please 🙂 Looks awesome! Btw, any special reason you did use SMD resistors for R12, R13? Did you use the 2SK208-Y(TE85L,F) or the 2SK208-R(TE85L,F)

-

goldenreference high voltage power supply (GRHV)

audiostar replied to Pars's topic in Do It Yourself

Looks like the GRLV v.44/.45, why? One of the best low voltage power supplies. It has its own thread, btw, link here. -

and now for something completely different part 3

audiostar replied to kevin gilmore's topic in Do It Yourself