-

Posts

2,292 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Events

Everything posted by Kerry

-

Here's some progress. I'm shooting for a chassis size of 8" x 14.5" x 3.33". Here's a few pics...

-

Thanks. Very fun stuff. If all goes well I will make the gerber files available. I don't mind a few mods. @StrawHat - The connector on the right is not .2 pitch. I use them because they are rated at 600V. The part no at mouser is: 571-1-770170-0. You should be able to easily find the mating parts. On the left side where the audio inputs are it is .2" pitch and I used a 5 pin gold plated connector and just pulled out the 2nd & 4th pins. That part number is: 538-22-11-2052. Kevin is very right about the soldering. It is very easy to have issues given the high voltage and closely packed components. I examined every SMD solder joint with a loop to make sure that they were good and there was no possibility of shorts.

-

I just checked the OSHPARK website and they don't list that in the specs.

-

Stuffing the boards. I've got to drill the heat sinks so I can mount the boards before I finish off the transistors.

-

@Lil Knight - I didn't know this site existed. Really nice. Thanks. I may have to get in on a balanced Krell knock-off at some point.

-

I used OSHPARK for the prototypes. It's $5 / inch for 3 boards (color standard). Expensive for larger boards, but works OK when checking the board.

-

Making progress... I just got the amp boards in. Here's the front & back. Here's one of the PS boards with a voltage doubler on top for the bias voltage. Parts will be in on Monday

-

Looks interesting. I was going for a small footprint so it would fit on my night table. I've just ordered the amp boards and should have them within a couple of weeks. Looking forward to testing the boards.

-

Nice and easy. I like it

-

It looks like things are coming along nicely for you. Chassis work is always very tedious, but also very rewarding when you're done What type of finish were you thinking about?

-

Very nice Wachara.

-

No. I was traveling on business last week and I'm only just getting settled. I've got a few things in front of this at the moment, but will definitely get back to it.

-

Beautiful job George. Congrats!

-

So beautiful!! I've got a similar sized block of ebony and will be attempting a knob and surrounds for the jacks.

-

Got the heat sinks in today. Here's how it's going to lay out...

-

Me too. I love the burl, but both are beautiful.

-

I just tested the first board. Everything worked great I've got to adjust the voltage down a bit but that's a simple fix. Ignore the heat sink on the MOSFET. It's just while I'm doing the unloaded test.

-

The PSU boards will mount against the side plates using stand-offs (approximately 40mm). I had SUMR build me a transformer that is 2.3" tall and 3.7" diameter. That gives about .25" between the transformer and PS boards. I'm hoping this doesn't cause any induced hum in the PS. I'll test before I mill out the chassis plates.

-

I've been interested in building a smaller version of this amp so I started playing around with a chassis layout and board layouts for PS and the amp boards that could fit in a chassis that is approximately 8"x3"x14". I blended SMD in with the amp board. Makes it a bit more difficult, but I wanted to experiment. Here's the project so far: The power supply... Requires two boards (2.5" x 5" each). The Output MOSFETs will mount directly to the heat sinks. The small board on the left is the adjustable voltage doubler for the BIAS. The amp boards will mount vertically against the heat sinks. I'm going with Conrad MF20-75. They are 200mm x 75mm x 48 mm. I haven't gotten to the amp boards yet since I wanted to get the PS up and running first. These boards are 2.5" x 6" each. This will be the BIAS. It supports two different voltages. This one is set at 500V and 580V. Still in the experimentation phase, but moving along. Will keep posting as I go through this.

-

Who are you looking at for that. I'm having some issues with a four gang POT. Very nice work on the panels

-

Since they are 6 layer boards, the price can go very high for low quantity. I priced 130 at $9 each and 150 at $8.43 each.

-

If you have a working side then use a simple diode tester for each transistor comparing left and right channels. You'll have to check each possible combination. This helped me resolve the issue in place.

-

Very nice on the PS Kevin. I was just looking at this and was wonder if the voltage reference was floating. I thought it should tie to ground but didn't see it.

-

Hi Al, Just seeing this now. Glad that the crackle is out for now. It could be any number of things, but I agree that the batteries could be a source of the problem. I would not recommend doing anything unless the crackle comes back. It could have been the combination/placement of the tubes. Even though they are matched there are still variances. The servos could have been operating near or at their max. I adjusted the batteries to what I believed to be the center of the sweet spot. If the problem reappears I think it would make sense to measure the batteries as a first step. We can take it from there. Good luck and I'm very happy to help out if needed.

-

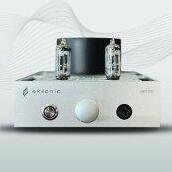

Big sound... small chassis... Looking forward to seeing the results.