-

Posts

2,292 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Events

Everything posted by Kerry

-

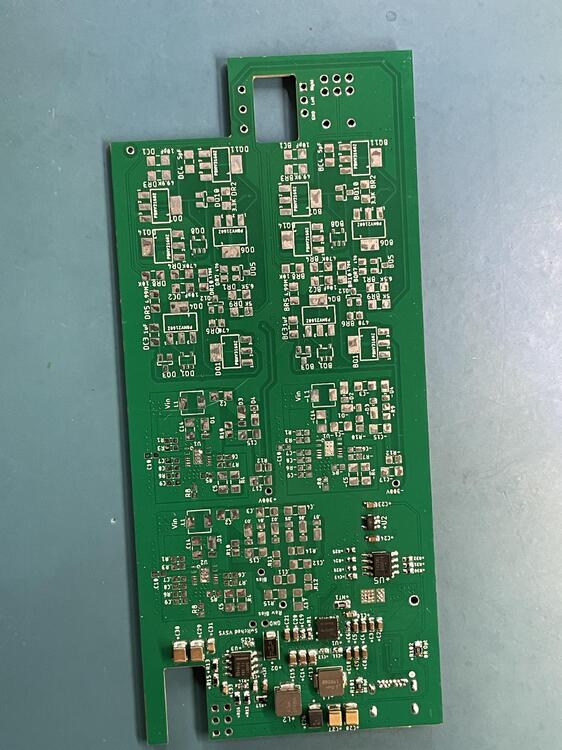

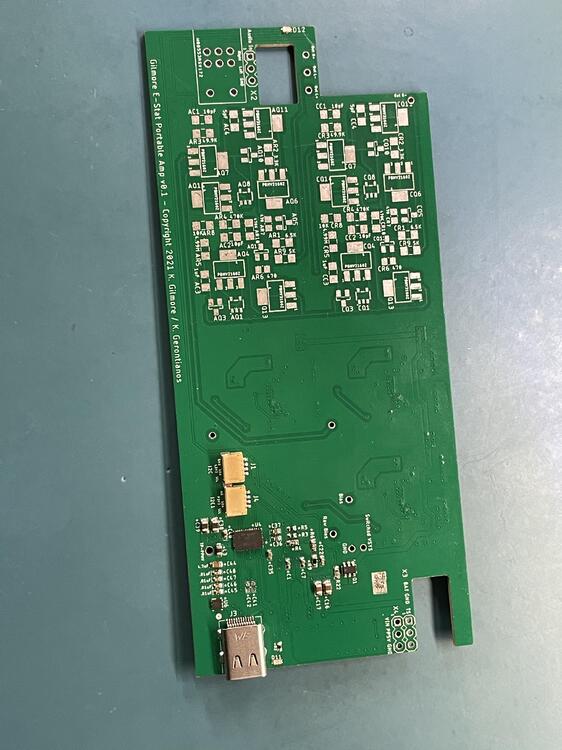

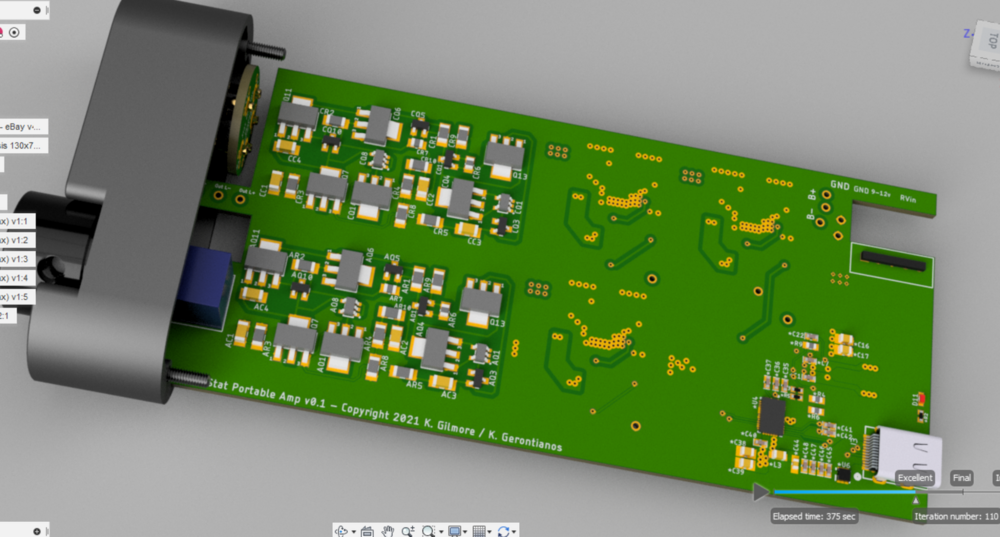

In other news, I just got back the analog input board and assembled the amp. The sandwich is 6.2mm thick + bottom components for a total of about 9mm thick. Batteries are about 10mm on top of the input board. Back plate on and plugged into USB-C (charging LED on) Why we did this... Portable music Just analog from my phone at the moment. DAC is up next PS The Weight is 12oz or 340g

- 128 replies

-

- 16

-

-

Here's the final board I just sent out to get manufactured... I added some more optional parts that help stabilize the current sense circuitry. The board is now 10mm x 58.4mm x 1mm. Parts are ordered, so it's a race to see if Mouser can ship my order before the boards arrive.

-

The USB-C and battery management chips are crazy insane. It would not be possible to solder with an iron. They both have one or more exposed pads underneath the chips. Here's the USB-C PD controller... Those giant looking resistors on the left of the chip are 0402

-

The TI chips I'm using for the USB-C and protection/balancer already have a mechanism built in, so I just followed their recommendations. I found some 0603 parts (RT1, RT2 one the board). They are 10K resistance to start and about 4.3K at 50 C. I found new batteries that are 2400mAH that should give a little over 8 hours playing time. Over voltage is 4.2 and minimum discharge voltage is 2.75V. I'm using 4.2V for OV and 3.0V for UV.

-

I just finished designing this battery protector board. It has a built in balancer to try and keep the cells at the same voltage. I added a thermistor that gets fed up to the battery management on the amp board. This also has it's own thermistor in the middle of the board. I'll set this to about 50 C for both and do some testing once I get this built. The board is 10mm x 56mm.

-

and now for something completely different part 3

Kerry replied to kevin gilmore's topic in Do It Yourself

SMD version of the CFA3 dynamic -

You’re hired 😄

-

Yes. Typo. Food coma

-

For D24, most people used LTL-4213 on the original builds. In the active batteries, I use a 7V reference and set the current down to .00093mA (3x 260k resistors). That puts about .23W on each resistor. You’d need to adjust the sum of R31, R32 to 14.7k If you’re planning on doing this, I can double check the values.

-

Thanks. I think I'll pick one up. I've had the amp playing from 9:00 this morning (did I mention it really sounds great ) and batteries were down to 9.8V at 3:20PM. They are not perfectly balanced so one battery is at 3.1V which is below the minimum 3.3V recommended. So looks like I'm getting a little over six hours with these batteries (3x2000mAH). I can look for larger batteries and also play with some optimizations. I've also been running additional 5V and 3.3V supplies for the DAC that consume extra power. They're not needed for just the analog input. The balancer should have kicked in to turn off the battery pack, but it didn't. I suppose it would have at some point, but I plugged it back in to charge. I have a different and smaller balancer that I'm going to try. Maybe that will do a better job.

-

Some more good progress. The amp is up and running I've got two issues on the board, but the amp, power supplies and USB-C PD / battery management are all working great. The wires going to the pot are temporary. There'll be a board for the analog/DAC inputs. The PD chips are small with lots of pins on them. I'm surprised I could solder them Lots of 0402 chips on the right side of the board... Here's the amp running with the battery (I need to have the input board done before I can put the batteries in the chassis). This is with the amp running and USB-C charger plugged in. Below, it is sending .18A to the batteries. The battery management will stop charging once the batteries are at about 12.5V. It drops the current as it gets closer to a full charge. With the charger plugged in and batteries fully charged, it doesn't draw any power from the batteries. At the moment, it negotiated 5V from the charger (source) and is boosting it to just above the battery voltage. If we wanted, we could source power so it could charge you phone too. I'll do a drawdown test tomorrow to see how long it will run on a charge. Overall, I'm very please with this amp. Kevin's amp design is fantastic. I've been listening to it for the last several hours with my SR-007's

- 128 replies

-

- 17

-

-

Happy belated Birthday Kevin! I hope you enjoyed the day

-

The board is two layers, but I had to use .5mm spacing for the USB. It also has a lot of 0402 components. I don’t think you could use a mill for the PD section. Also those USB and battery management chips were a nightmare. It’s funny that after placing all those 0402 parts the 0603 stuff seems easy and the 0805 parts seem gigantic. I used an oven to bake it since I was afraid the hot air station would blow those smaller parts away. The DAC will use the XMOS input and will be on a separate board. We’ll have a version of the input board that is analog only.

-

I wanted to add my thanks here as well. Greatly appreciated Todd!

-

Making some good progress on the amp... I’ve got the USB-C PD all soldered on and ready for testing Here’s the face plate with the jack Here’s the amp assembled, but I still need to finish the power supply and amp sections of the main board

- 128 replies

-

- 19

-

-

That looks beautiful!

-

Very glad it’s back and thank you!

-

Looks great! So if I’m reading this right, more projects means more beer. That sounds right.

-

That's what I was thinking. If I used 1mm boards I think I would be fine. The power supplies have parts only on one side, but the PD / battery mgmt needs parts on both sides. The cutouts would be easy enough. I'm not sure what I'm going to do for the initial prototype. I'm pretty close with the current board and I may just build one. Seems like I should sleep on it PS Interesting. Are you working on a balancer / protector or the management components?

-

I'm considering that. It would be nice to have one board for each component so they could be tested separately as well. Each supply, and the USB PD/battery mgmt could have separate boards. Everything else is DIY solderable and could go on the main board.

-

Making some progress on the main amp board. It will have a USB-C PD port so it will accept 5, 9, 15 & 20 volts. I think a 20W charger should be enough, but I'll have to test that once the prototype is built. This is getting pretty dense. We'll have to have this partially assembled since the PD stuff is going to be a pain to do. There are 0402 components in addition to some of the larger chips with multiple pads under the chips. This has 4 amp channels, +/-300V supplies, 580V bias and now the PD stuff with boost / buck on the input and includes the battery charging components as well. Looking at using 3S lithium batteries. The board is currently 161mm x 61mm and I think I can fit what's left. There's still more to do, but here's where I'm at...

- 128 replies

-

- 11

-

-

I use an oven (when it’s not too cold outside) and a hot air station during the winter. I agree that you need to set the air velocity way down. I do keep a tweezers handy in case something moves or tombstones, but I generally don’t need it. Try to have the air gun directly over and perpendicular to the parts. I move it around in small circular motions anywhere from 12mm - 25mm above the parts. It’s very important that the parts are somewhat centered in the pads. For 0603 and down, I use a loop while I’m placing the parts. Once you get the hang of it, it’s a very fast way of soldering.

.thumb.jpg.52e812f9d15945e4fa002ef873e2ec6a.jpg)

.thumb.jpg.a574abc759fbfd123f6e89e8ec763256.jpg)

.thumb.jpg.e87aa876080a3c7cf354a9fdd9330345.jpg)