-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

Where is your Tormek? Also, Rob’s big thing is 30 seconds to sharp so if it takes you a week you must be watching the wrong videos.

-

Well. The Oneida dust hose came loose from the jointer and whipped through the shop and flipped the bench. I knew that thing was a nuisance.

-

-

While I was tempted to leave the top unfinished as I liked the look, I decided that this will be primarily a poorly devised assembly table and not really a hand tool bench so protection for finishes and glue took precedent. Therefore, I rubbed the bright yellow snot all over the top also because from what I have read it will give better protection than the Danish Oil.

-

Applied a first coat of Tried and True on the base (ash). Kind of wish I had treated the Ash with a water based finish, as it went from looking okay to looking Home Depot lumber real quick with the yellow tint.

-

My main concern with the tried and true is that I did the shelf with that and sawdust seems to stick to it like crazy. Maybe I did not rub off enough of the excess, I kind of treated it like I do Odie’s with a sander buffing pad to remove excess.

-

Thanks guys. Luckily none of you have to see it in person to pick out all the issues I have. Next poll, which finish for this thing. I know Naaman used Tried & True and some big bench nerds recommend Waterlox and about everyone else recommends Danish Oil. Cannot decide. Al, since you guys convinced me to add them to the other side I will only have 6-8 leftovers. If you want to use them on your bench let me know. The require a 1 5/8” Forstner, 3/4 auger and a Brad point 3/8” bit for the magnets that hold the dogs at whatever height you want.

-

-

The 3/4 holes were just going to be maybe 3 in the middle for the hold fasts. Mostly for domino holding, etc. Looks like the Veritas ones work great if I remove the dogs from the In-Kleind setup.

-

I will have some regular 3/4” dog holes on that side for the Veritas whatever dogs/hold downs. Might start getting Swiss cheesy, but I guess I can supposed use them with the 3/4 through holes made for the In-Kleind bench dogs.

-

I am down to a decision point on bench dogs. I have almost 20 extra so I am trying to decide if I run a strip down the opposite side of the bench for symmetry or just stay with the single run of bench dogs. Any opinions????

-

I bought 24 and at the moment only think I will need 7-8, so I am going to start putting dogs on everything.

-

Yeah, probably just not supporting it properly but the saw worked very nicely.

-

Makes sense. Moved to the dogs as the vice and ends were pissing me off. Not mine. Even with two rolling stands, getting the things up on the flexy stand and the rolling stands at the proper height led to an end slightly better than this one. I used a straight edge to set the stands as there is really no way to set them with the top on the saw as the thing flexes as soon as the top is on. The flex still happened so no matter how much I adjust one or the other rolling stand, if I had to move the slab again for the cut, immediate need to redo everything.

-

Review of the Makita. Made the cut, almost as deep as a needed. Dust collection seems to be there for looks only as all the dust shoots straight out the front of the saw and I ended up with an end that is less square than when I started. Festool track squared for the straight cut and clamped to the work piece but evidently the Makita was leaning a bit. Might have to read a manual.

-

It would probably do better at pasta than vicing. Been fighting it all day due to the completely twisted maple vice jaws. Of course the other Vice showed up without the jaws at all so not sure which is worse.

-

I bet the WWII does not have that problem. Fucking Sticky Nubs shill. Got the threads in for the side vice and things seem to line up.

-

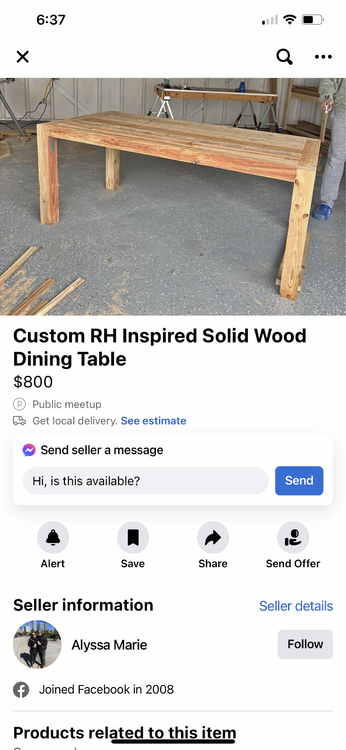

I assumed, as they were so prominently on display as part of the design and based upon the cost of the table, that they are actually made of Vibranium. Knowing that, killer price for this piece. Thinking about making an offer and saying the deal must include the sweatsuit and hammer.

-

-

Unfortunately, if we built a trebuchet here at half-assed woodworking, it would undoubtedly fling the burning cloths directly into the finishing cabinet when the shitty build failed.

-

Watched it this morning and ordered one of these minutes later as I have a ton of oil finish to put on this bench soon.

-

-

-

Seems fairly cumbersome. I did look at the big Mafell track saw there but it does not cut deep enough. I think I will just rig something up with a roller stand or saw horse.