-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

So much fun cutting hardwood drawers for Blum undermount slides only to come up short because i did not carry the 39/64 of an inch in my calculations. Appears I need to mill all new fronts and backs to get to my 31 29/32 drawer box for these silly fucking slides.

-

I bought some Seneca tool for that but have never taken it out of the box to try it. The scrap wood/HD Plywood built in is coming along. Need to decide now if i go full CanaryWood drawer fronts or all maple fronts with canarywood pulls or inlays. Going to put some big bevels on the bottom and little ones on the top of the “scrap” top and then throw drawers in and hope my measurements were actually correct. 🙂

-

Milling up all the left over Maple from the bench to make a benchtop for the new Maple built in for my closet. Cannot figure out how to incorporate the bench dogs/vice in the dresser, but I think I can at least make some Jotoba drawer pulls.

-

Wrapped up the tea box. Used the Shaper for joints/hinge/mortises/tea cup. Quartersawn Oak, Sapele and Bubinga.

-

Well, it is an Irish name.

-

I am YouTube minimally-famous.

-

Threw together a little quartersawn tea box today with box joints and dado for the bottom all done with the Shaper.

-

Templates is my primary plan, as my small CNC is designed to only accepts boards slightly shorter than anything anyone would ever want to template, ever. If i had a Naaman level CNC i would probably just hook it to AI and let the internet spit out templates for me all day. AI seems to be a better designer than me.

-

I think it largely has benefits where it can work on large finished projects that cannot fit on a CNC (6x6 cedar post, hardwood floors, completed workbenches that were really to thick to fit under rhe gantry of most/any small CNC machines anyway) and it can do the joinery that the majority of small CNC machines could never manage due to the lack of vertical tables.

-

I would think it would make more sense for a pro in the field like yourself than it does to someone like me. I will probably use it to put the logo on the bench vice and then do some carvings on the 6x6 cedar posts for my new mailbox and never use it again. I guess I need to try dovetails to see if it is better at those than the leigh.

-

Thanks guys. Played some video games tonight in the shop to come up with a small 2x2 brand to go on the boring maple chop.

-

Got the last set of maple vice jaws from In-Kleind and the mounting points and through holes are almost a full 1/4” off center so that required dramatic work to salvage and keep the length. Now that I have the maple vice jaws on, I think i am going to build more Jatoba jaws as the Maple bores me.

-

Do any of you guys have the Pantorouter thing? Thinking about trying this out for joinery.

-

Nice contrast between the Jatoba from Andy Klein and my own, so I do not have to make Maple bench dogs.

-

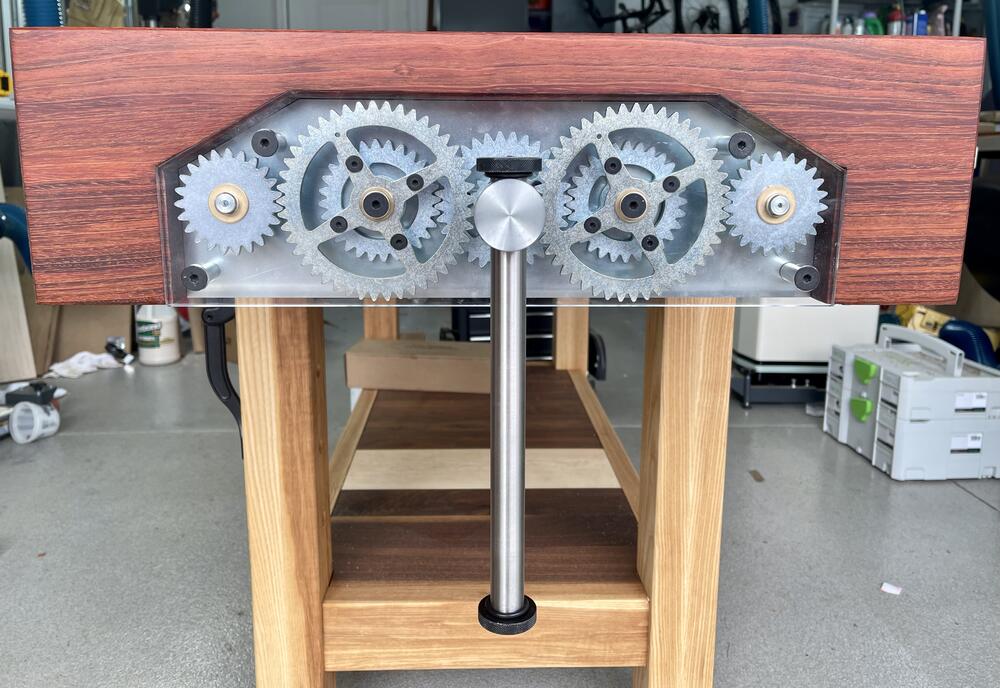

Ahhh, that nerd box on my CNC.

-

Are we talking power or some other nerd thing.

-

Did not even realize a three phase spindle was a thing. Maybe I should look for one of those maker spaces so I can throw my shitty CNC away and put something worthwhile there.

-

All out of sunlight so no glamour shots, but I declare…Jatoba vices are sexy vices. That is all. (Sapele racing stripe for bonus points)

-

I guess I am going to give up on the $280 worth of CNC cut maple jaws from Andrew Klein, as he seems to be ignoring e-mails entirely now, and make my own. Paid for them a month ago and nothing yet as he forgot to send them with the vices.

-

Not simple. Those rabbeted corners had me thinking you had mitres that I could not even see there for a second. Oak legs or some sort of accent?

-

-

-

Yeah, if I fell off a chair I would make up a story also.

-

Make sure you make a secondary bevel at exactly 27.76892 for ultimate slicing your fingers open while not paying attention.