-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

Do any of the SawStoppers use the folding out feed table? Trying to decide whether to get that to save space or build a work table/out feed table with storage and sacrifice the space between the table and the router table. The folding one seems to interfere with not the Industrial mobility and the dust port.

-

Not sure my knees and back will ever recover, but I think I am done outside of leveling the zero clearance and setting up the blade.

-

They evidently hired someone from Festool to design the power controller mount as well. “Please mount screws in a location inaccessible with human hands, built within a steel enclosure so no light can ever reach the screws and then be sure in the instructions to have them install this right after they install the wings; as it would be way too easy to put this on before the wing install”

-

Makes sense, I just assumed they would make them the same size.

-

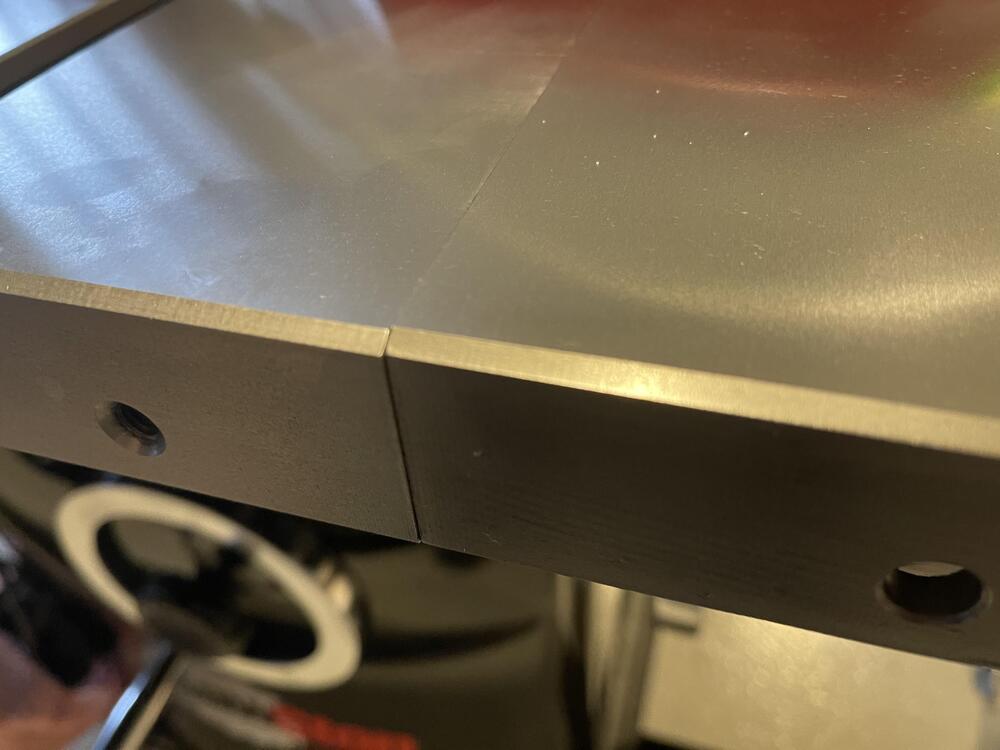

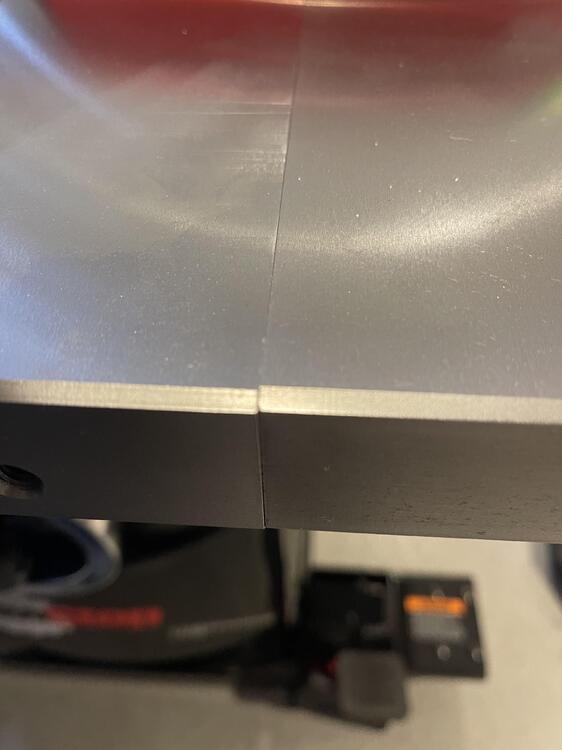

Without grinding the table down, not sure how the length of the extension can be stretched to match the table. I am talking about how the side edges are not matched if that was not clear. Like the wing is slightly shorter than the table.

-

How much variance do you guys have in the table/extension match. I have it perfectly lined up in the back of the saw and have this much variance up front.

-

I guess I have wd-40 as well. Tried the paste wax but not liking the streaking after buffing so might move to the Boeshield for future treatments. I figured it would need something as every other steel thing in the garage likes to rust.

-

Made it up to the extension wing mounting before I decided to take a break. The only issue so far is the Festoolian location of the elevation hand wheel set screw. I have the oil cleaned off the top so I want to treat before shutting down. I have Boeshield T9, Johnsons Paste Wax, Fluid Film and Slick Kote. What is the HC steel protectant of choice?

-

Managed to accomplish a shit ton working all day today on the SawStop. Picking the saw up in the store is most definitely the wrong idea.

-

That is more or less my plan. I think taking the extra cast iron pieces out of the box should take the weight down to 330ish lbs which I should be able to get into the garage.

-

I used Bourbon Moth’s tutorial on Youtube and used plywood carcass and poplar face frame and doors as they were painting those. I used the Blum hinges which worked really well with the Rockler tool. Forgot, I also used pocket screws, but the Castle kind, which are so much easier to work with.

-

Did you get it delivered or picked up in the truck? I am still brain storming how to get the pallet out of my fucking truck. Even slamming the air suspension to the lowest mode, it is a pretty good lift for 400ish pounds off the tailgate.

-

Unfortunately I do not have an apprentice to help so I am going to be working with balance, brute force and luck. I am thinking 3 days minimum, not including hospital time after trying to lift the thing onto the stand. The local dealer WSI Machinery seems to be great. Mostly giant industrial stuff but a full retail store with SawStop, Festool, SCM and a few brands I did not recognize.

-

I will say, it seems that SawStop should be making the Industrial Base already prepped for the PCS as an option. Doing the conversion with the loctite and soft-ass Allen screws is a PITA. If they are going to put on loctite, they might as well do it at the PCS sizing as well for an option.

-

-

Found it in stock 5 miles from my house at a big Felder/SawStop dealer that I thought was mostly a heavy equipment kind of place.

-

I assume all you SawStop guys are using the industrial mobile base? That is the only part I am waiting on and cannot find them anywhere local. Trying to decide if I just go with the standard PCS mobility cart and live with the lack of mobility.

-

Yeah, I should have finished all the cabinet doors for the parents attic storage before I sold the little SawStop. It is going to take me weeks to unload and build out this saw.

-

Looks decent. I think I like the brakes on the Festool better than that system but the gauge for bag fill and stuff would be nice. Going from the Sawstop Jobsite Pro which just required I pull it out of the box and put the blade on to the new PCS with 20 boxes and having to build the whole thing is quite the adventure.

-

The Hilti seems nice. Hilti seems to have the auto filter cleaner which I believe does not come with the HEPA filtered Festool. They also mention a BT remote for battery tools but I did not see if that is like the Festool or just a handheld remote.

-

I think the Festool Vac is the best thing they make. No idea about Hilti, are you talking about their construction wet/dry vacs? I am selling the little sawstop tonight and picking up a PCS tomorrow. Going to sling up some kind of ceiling harness that I can use to Mission Impossible around the garage to use the different pieces of equipment.

-

Building some cabinet doors. Trying to decide between 1/4 birch plywood and mdf for the panels. Rail and stiles are Poplar. All doors are going to be painted. Any sage advice?

-

Yeah, I watch all those guys. My issues usually arise with equipment, e.g. I have no jointer so I use a sled on the table saw, table saw sled can only accommodate about a 16” board due to the tiny top on the job site so cannot joint, leading to issues. Then don’t get me started on trying to finish a 42x30 crate on plywood sheets on a table in the garage as it is too cold to do anything outside so I could use all the spray equipment piled on a shelf.

-

Thanks, but it is all the picture angles, if you could see the screw ups, you guys would probably ban me from the thread.

-