-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

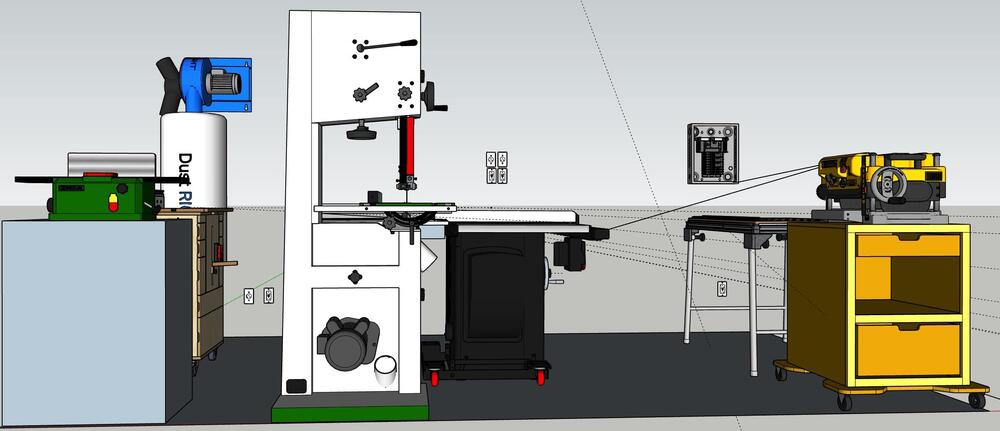

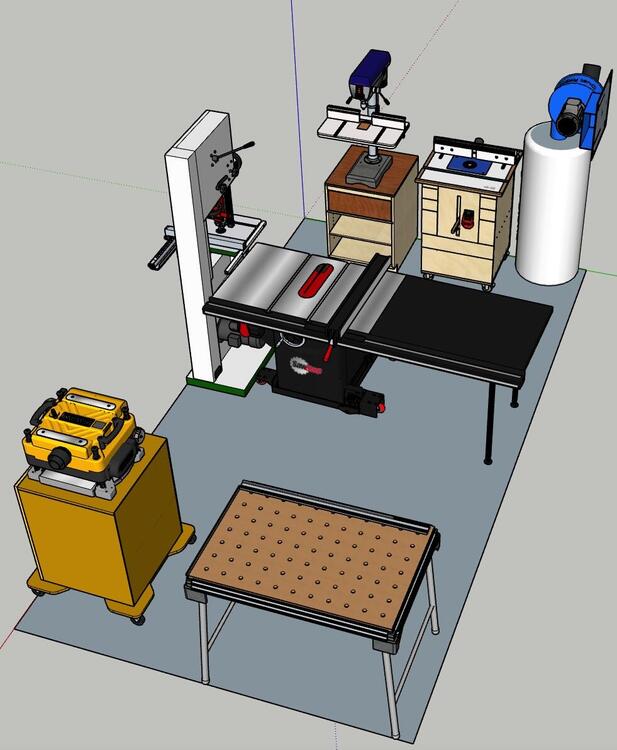

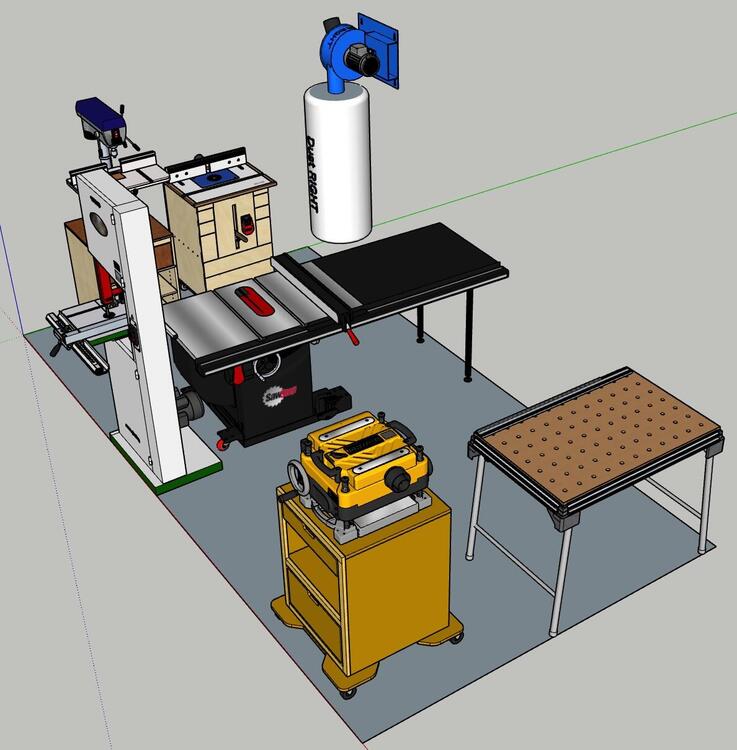

Trying to layout outlets for the electrician to run. Thinking 2x220 in the middle, plus a quad of 20amp 120 and the existing duo of 15amp 120. 20amp pair by the MFT for the Festool equipment and then a 20 amp for the dust extractor with an extra 220 for future upgrade there. Might run a 230 and a pair of 20 amp to the ceiling as well.

-

-

Voltage Conversion is super easy. Changing motors is slightly fidgetier.

-

Going from a shared 110v 15amp for the whole garage to dedicated 220 or 110v 20 amp circuits per tool will be a game changer. I will be able to cut wood with the lights on again. 🙂 Trying to decide now if I just buy the 3.0 HP 220v motor from SawStop instead of doing the conversion on the 1.75. The SawStop guy said it was not necessary for most shops, but at just $500 more it seems worthy.

-

Upgrades have begun. New 100amp panel being installed and I get all the interior runs Monday when I get back from California. Saw Stop conversion ordered Band Saw converted

-

Managed to manhandle the shop fox off of the two pallets and onto the massively shitty shopfox stand they recommended. Going to have to order something better for the rolling cart but the saw seems okay for the low price.

-

I bought several options from them for the upcoming furniture. Got to attend a demo at the hardwood dealer and I really liked the end results.

-

I actually have two dust collectors, a rolling 750 that sits with the drum sander on the other side of the garage and the 1250 hanging on the wall. I have been raiding the 3D collection trying to layout my equipment in my tiny space. Think I will have to turn the bandsaw and let it stick into the other space when I am using it.

-

Woodworker II. 40 or 46t, I think, stays on all the time here. I have been trying to figure out dust collection without too many blast gates, etc. on my crappy little 1250 Rockler system. Going to end up spending more on hoses/adapters than the cost of the saw. I assume you guys all use both ports on the bandsaws?

-

I only watch for the soundtrack and dance sequences.

-

The 1849. I can get upgraded bearing guides but it appears the ceramic ones are reserved for the Grizzly ones. I figure since I have no skill; and I am having trouble even figuring out what kind of blades I need, the crappy version will be okay; and I can flip it later if it sucks. Reviews, though few, seem to be very good.

-

Maybe I will come up with a less fancy copy of the design for this dresser. I got a pretty good deal on a lower end resaw-capabilish bandsaw, that seems to be well liked by Wood Magazine. I had seen people discussing saving the shipping cost ordering through HD, but the price dropped $550 today. $1300 shipped for this one from Shop Fox. Not sure if it will be worthwhile; but should work for my needs for at least short term. https://www.grizzly.com/products/shop-fox-14-2-hp-resaw-bandsaw/w1849

-

Looks like you are ready for your YouTube channel Al. I am looking at all of the Hammer bandsaws. I think the slightly smaller 3800 may be best, but I cannot find it on their store, only the 4400 and the N2. You aficionados know if they dumped the slightly smaller 3800? Also, any ideas on how I might make a knock off of the drawer pulls for my vintage MCM furniture for the new dresser?

-

Drama. If I did not have so much Incra stuff I might have considered the Harvey mitre and sliding table. Stumpy’s response seems super sponsor directed to me.

-

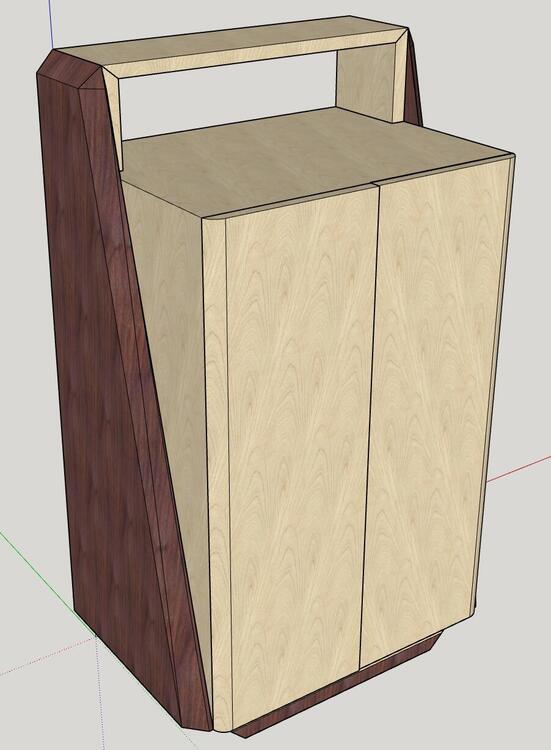

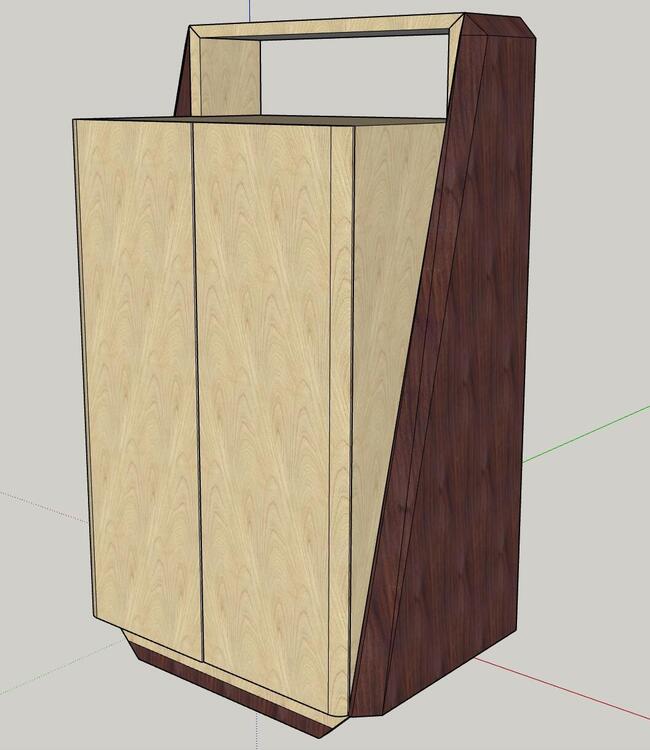

I was contemplating a single piece leg for both legs made of the 8/4 Wenge I have laying everywhere, I just could not figure out how to do that in Skethup. I really do not trust my skills, or lack of bandsaw though so I am looking at other ideas That being said, are you guys with the Hammer bandsaws using their blades or some Murican ones with proper measurements? Also, I want to see more of Naaman’s 3D shop. Do you have everything modeled in Fusion?

-

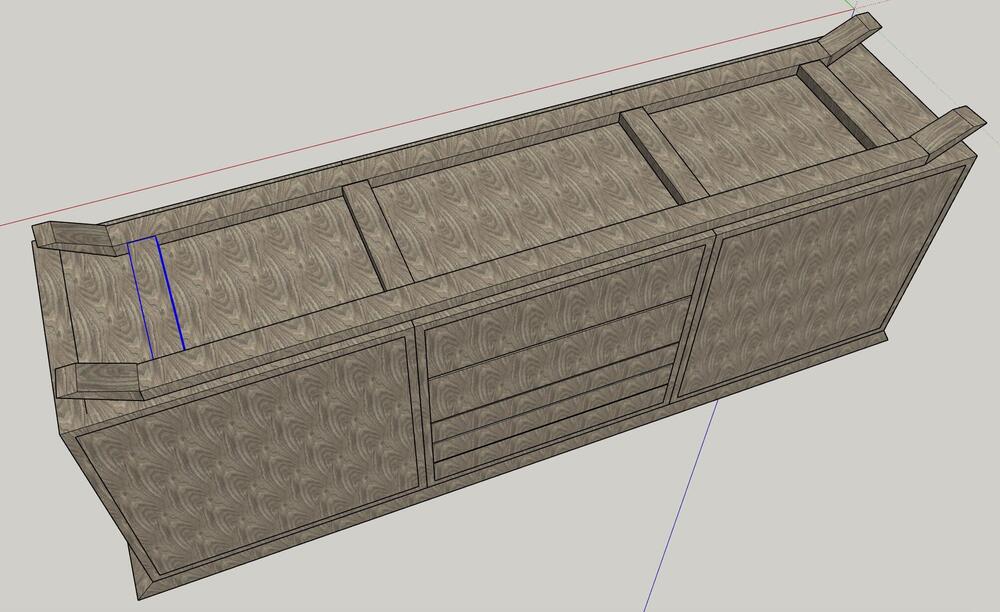

So much fucking storage. I would love half the drawers but I kind of like the idea of vertical pull out trays for mounting woodpecker stuff, saw blades etc. I am sure you have all that stuff stored elsewhere already.

-

-

While the shop is shut down until the electrician decides it is warm enough to run the conduit outside, I have been trying to learn Sketchup and model some of the projects I am in the middle of. Kind of clunky at first but it works pretty well you you figure out all the tools. Need to download some more wood textures as I do not like the Walnut I have and there is no Ambrosia Maple, the lighter wood in this project.

-

I was looking at the parrallelllaggrammmm thing and decided the extra depth of the cabinet was not worth the minuscule amount of accuracy that may be gained. Accuracy that is all destroyed by my shitty craftsmanship.

-

I assumed Doug was recommending a jointer made by 92 year old dwarves that have been made by the same dwarves for 72 years and end up being harder to use than sand paper in jointing, so I can earn the flat surface. Anything Naaman recommends only fits in his ever expanding garage, weighs more than my truck and takes 320 weeks to show up.

-

Best 8” jointer without 18 month wait list…Go

-

Finally hired an electrician to put a 100 amp sub panel in the garage, but now he seems to have gone quiet so no idea when it will actually happen so I can use the tools in the shop again.

-

When are you doing your 2022 Shop Tour Naaman?

-

Or the drawer/door faces’ cope and stick construction.

-

I thought the same thing but I have not tried to measure. He said as soon as I said it rumbles and then goes to alarm that he knew the problem. Basically the alarm triggers if it does not get to 4K rpm within a time period. If the draw does not allow this, the stress on the motor, he says, is the equivalent of taking a hammer to it I do know that the circuit trips at least a couple of times any time I doing anything in the garage. Fucking Festool CT26 set it off once, just vacuuming up sawdust off the saw. They said 20amp would work so I am working on getting a 25a circuit pulled to replace the 14ga wire/15a circuit to get me by until things become more normal. If that is not feasible I am just going to pay the 4-5k for the full rewire and panel, which is what I should have done to begin with, just pissed off about the COVID pricing for something so simple.