-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

Well, part of the magic side table arrived. The rest is somewhere in the UPS system. Has shown on the way the whole time, even though the manufacturer is only 5 hours away. Not looking good.

-

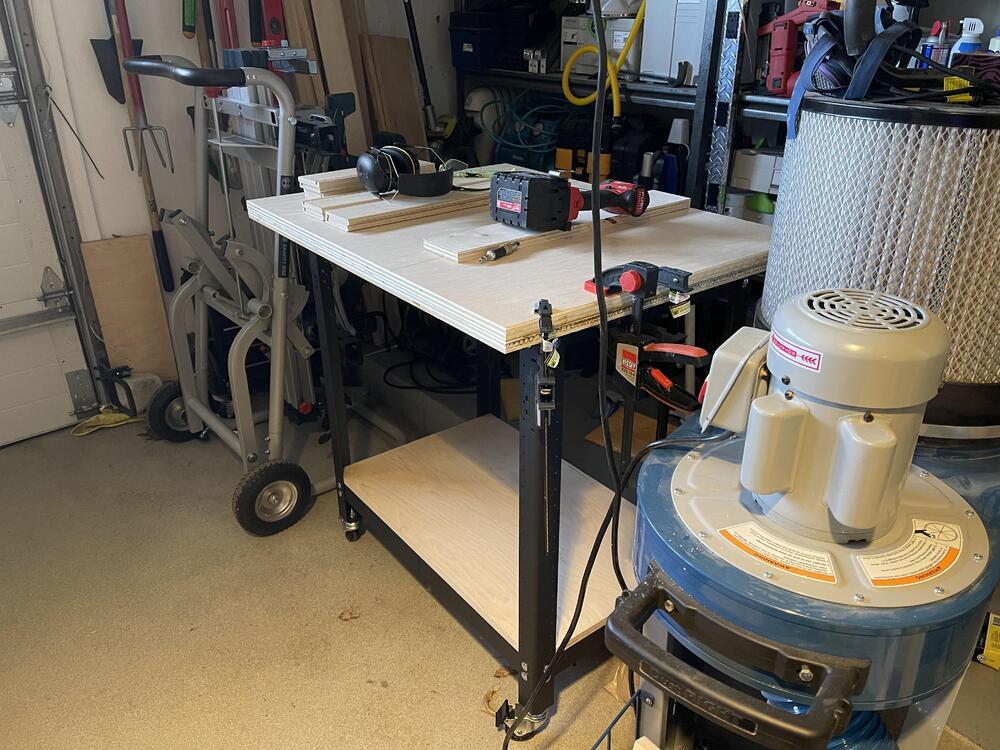

Threw together a little stand for the magic side table that is supposed to arrive tomorrow. Need to take the flush trim bit around the edges as I did a lazy glue up on the lamination. The Rockler stands are certainly not the easiest to get square, but seem good enough to support the magic side table, I hope. Having the drawers/shelves will certainly help. Going to run shop vac up to a spring hook in the ceiling to give me dust collection of I can make it work.

-

Looks like I will be spending the next few months trying to figure out how to work my magic side table. V Carve seems reasonable enough for really basic designs, my forte, but there is a ton of stuff to figure out.

-

I am thinking the best way to go now might be an even smaller Shark SD120 CNC and the big jointer. Little CNC will be about 60% the cost and seems to be decent for the template making and basic CNCing I need to do.

-

Time for a poll. I am looking to shove one more giant piece into the garage. Which would the HC Woodworkers think the best thing to shoe horn in? 1. 8” Jointer Powermatic or Jet seem to be the only ones shipping these days. (I mostly use a sled now on the Planer) 2. 32”x32” CNC on a folding cart (Onefinity) CNC would be slightly easier to store, but not sure if it is worthwhile for such a small work surface.

-

Since none of the real wood workers are sharing any work lately, I decide to share the latest from Half-Assed Wood Working. My dad’s buddy sent him to some Etsy seller with plywood beer caddies, so I had to step in. Certainly not perfect, but I am happy for my first attempt.

-

I think he uses a voice modulator for the Bourbon Moth videos, but that is his real voice.

-

Steve’s favorite YouTube woodworker, before the beard.

-

Finally decided to just go buy the Shop Fox sander at the local place and was surprised to find it over $100 less than the Amazon price. #Winning

-

Now that you mention it, I have a OneFinity 32x32 CNC on order and in the months I have to wait I am trying to decide if the little one (only thing I can barely fit) is even worth it. I certainly cannot build shop cabinets with it, but for some customization I think it might be nice.

-

Tried to watch that three times and I am no longer in to wood working. Three hundred templates to build a fucking step stool.

-

Looks more like box joints. I am thinking a shop step stool kind of thing.

-

Managed to get this thing installed, with instructions that seemed to be written in Chinese, then translated to Russian, then Portuguese and finally to English. Even funnier that several parts in the box were not even mentioned in the instructions and you just have to guess what to do with them. Luckily it is a very rudimentary device. Now all I need to is to come up with something mortisey to build.

-

While duck tape or sealant may work, I was probably going to sell this and get a real system (Oneida) to mount in its place before too long, so returning for full refund makes the most sense.

-

Looks like the two month old Dust Right is already developing a leak along a bad seam. So I guess I have to uninstall the whole fucking thing and take it in for a replacement. If I have to go to that much trouble I might just get the money back and get a real unit for the wall.

-

While it has a lot of goofiness. I am actually enjoying Jimmy Diresta’s new Netflix show. Interesting problem solving and builds at the demands of children’s plans. One of the OGs of YouTube woodworking and his goofy friends.

-

Yeah, a thin pull strip of leather, wood or metal on the bottom would probably be the best bet as that will also lift it up a bit to get more uniform kerf lines.

-

Today’s bandsaw box. Before and after a mineral spirits wipe down. Cannot come up with a proper knob that does not impact the continuous grain. Any ideas? I am working on a detachable rare earth magnet solution now but it is kind of clunky having to keep a Wenge knob/magnet lying around.

-

Looks like the issue with the SawStop was more than just power. Getting the same alert periodically and going through tests for SS. They are sending a new brake as that is evidently the brains of the whole system and I am trying to loosen and blow out a circuit board that is mounted somewhere that needs Festool hands to reach and the Anti-Brent head to even get in there and see.

-

I do not think I had the tension quite right, as it seems to be witchcraft of pushing hard, but not too hard, and seeing if it moves more than a 1/4”. Very scientific. I am also trying to figure out the euro style guides as they have so much give, it just does not seem they can provide the same stability as the typical bearings or ceramic blocks.

-

Happy Birthday Nate.

-

Figured out I am just as bad at bandsawing as I am at the other sawings. Tried to build this but found even with the 1/4” blade I could not cut smooth curves like the YouTube guys. Also managed to combine CA glue and wood glue when mounting the handle, then walked away without cleaning up squeeze out and left myself with a glue line I cannot manage to sand or chisel.

-

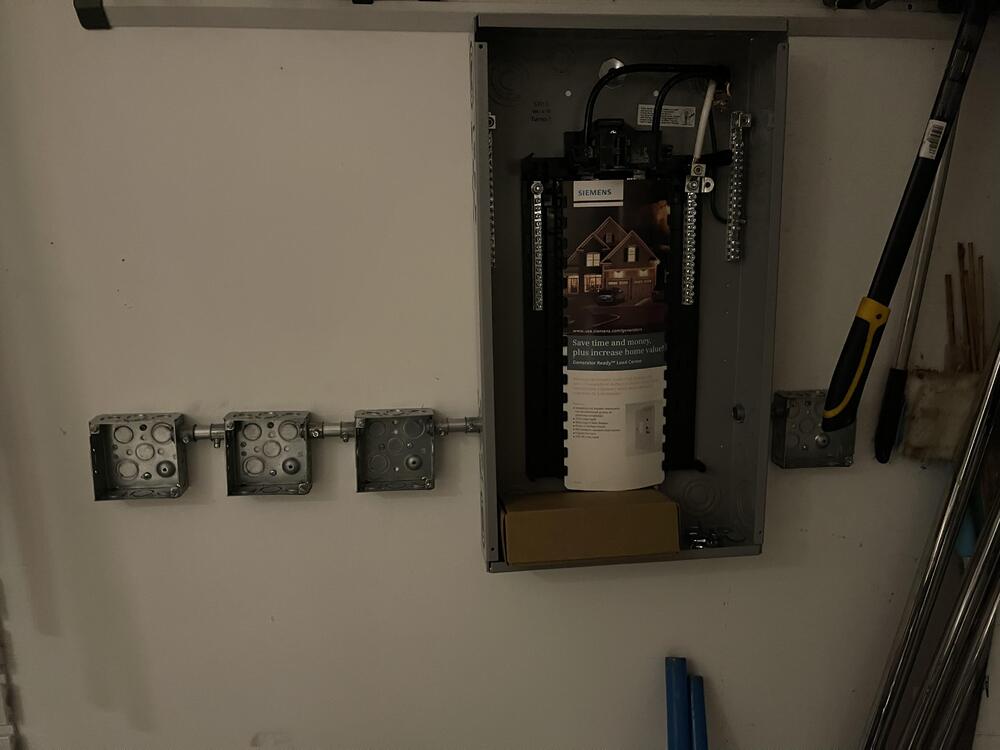

Fancy. One wall is done in the garage. I now have 23 outlets on that one wall, where I had 2 to begin with.

-

He is just Polish. He intends to install about 700 outlets as far as I can tell, even though I only asked for 5.

-

Fucking electrician worked all day to wire the panel and install 4 outlets I did not want all within 12” of the panel.