-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

Yeah I guess it all come down to comfort level. At the moment I am still in setup mode as getting a perfectly flat table and wings has been a bitch and I either have feed rollers too low or pressure on their springs too high as the boards do a nice little hop when they come out from under the outfeed roller.

-

Do any of you experts have thoughts on minimum board length for the planer. My new one shows 6” in the specifications which is much shorter than I would expect. I will probably just use the drum sander for the short ones 10” so I do not get 3HP worth of Sapele in the gut.

-

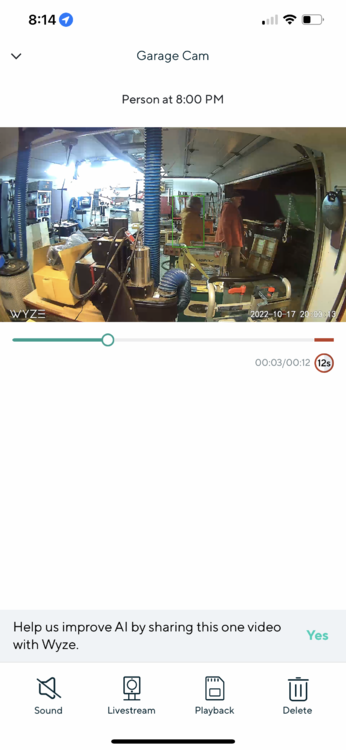

Or is he a genius???????????

-

-

-

It is in the shop. Now just need a way to lift it off the pallets and put it on to the rolling base.

-

Just to make Doug shake his head in disgust, I upgraded the Dewalt planer during the two day sale at Grizzly. I KNOW, I should have just bought a Hammer combo. I am not a smart man.

-

I really need to hire an intern for finish work. I suck massively, especially when doing a million angles as I get at least one streak in every coat. As good as I can get it.

-

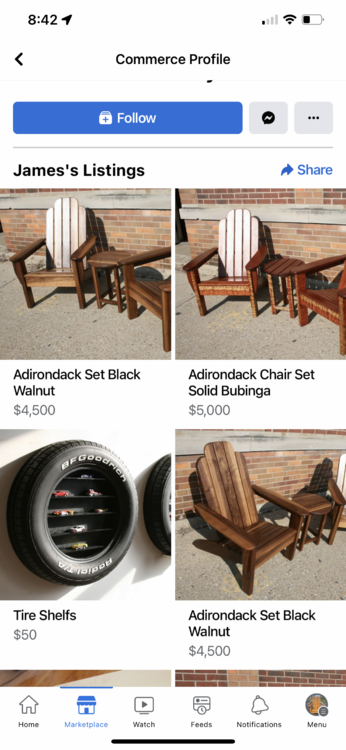

So I ended up putting the legs on but I am not entirely sure I trust the 150 hipster’s design to hold real people weights. It is just two areas of glue up and 4 2” screws per side (my addition). Trying to figure out some kind of reinforcement I can throw on the chair so I don’t get sued when it collapses under someone.

-

I have total boat Halcyon, so Halcyon it is as I have too much stupid shit to do this weekend to go shopping. So far just put the Total Boat varnish sealer on.

-

Okay wood peoples, what are your preferred finishes for the outdoor stick furniture? I use penetrating oil for the cedar sticks but contemplating a Halcyon boat varnish, teak oil, something else for the Sapele/White Oak lounge chair. Probably 30% sun and direct rain/snow exposure.

-

I am kind of surprised this type of device is not for sale somewhere. Bridge City tools stopped making them and no one really jumped to get in the market I guess. I figured there was bound to be a $75 Woodpecker version. That being said, I have much bigger issues than clamping at this point as I banged through all the 10mm mortises on the legs and about one of every four on the legs is canted slightly meaning I have to use a kutzall file to shape the tenon to get everything to fit. Not sure how I fucked that up.

-

I was trying to find some on the market but could not find any so going to cut them on the CNC. Do not have a 3D printer.

-

I guess I need to learn to do more fancy stuff with my tablesaw. It mostly just cuts lines. I am trying to make some angled clamping blocks for the lounge chair project. Do you guys think 3/4" plywood will be strong enough for clamping or do I need to cut these in hard wood?

-

Is that mostly hand tool joinery? Awesome. I would love to have something that nice in my house.

-

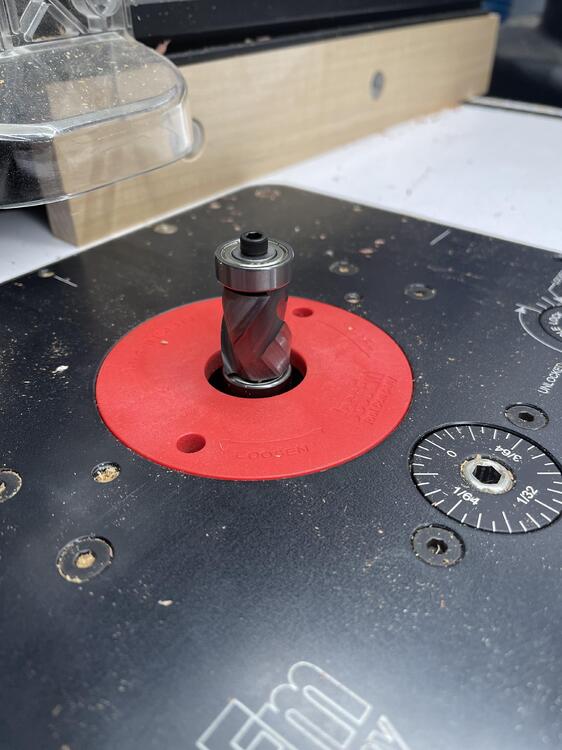

It is fairly violent compared to most of my router bits. Especially since I took off my start pin when I was routing long rockers and now have no idea where I left it. The cut it nice if you can actually hold onto it. The right side (shiny) is the handheld with a 1/4 template bit and the left is the whiteside UFT.

-

Yeah, my primary problem is the thickness of the legs. 1 3/4” and the ultimate is only 1 1/4 so I had to start with handheld router to copy the template onto the wood and now I will use that cut out as the template for the big bit.

-

Yeah. This is the new jointer, but going through threads on Grizzly/Shop Fox to see if anyone sees this issue. Most have problems with misaligned pulleys so I will go with what the plumb Bob is showing me and move the cutter pulley back a 1/4” and see what blows up next. Speaking of blowing things up, time to try flush cutting with this beast.

-

So regardless of the coplanarity, I decided to use a digital angle gauge and zero it on the top pulley and see if the motor pulley matches and it is a full 2.4 degrees off. Not exactly accurate due to the gauge but seems excessive and could certainly be attributing to throwing the belt. The motor mount slides down at an angle on the dust chute so I am having trouble figuring out how to level the pulley. Shims under one side???

-

That should fit. I think my primary problem was following the instructions and letting the motor pull the belt tight, but the shitty design makes it bind up and not get the belt tight enough. I ended up flipping a squeeze clamp and push the motor down to get a stretch on the belt.

-

I have a ton of straight edges, but none this thin. The space for placing the straight edge is less than .5”.

-

Any thoughts on a straight edge that will fit in this space to check coplanarity of the pulleys? Would need to be 18” long and only .5” wide the best I have come up with is a plumb Bob and it seems to show it being well out.

-

Did a ton of bandsawering for the legs and seat edges for the chair and managed to make a giant, expensive pile of weirdly shaped cutoffs I need to come up with a project for.

-

The Sapele is certainly looking nice after jointing. Also, I should have gotten the big jointer and automate dust solution a long time ago

-