-

Posts

9,101 -

Joined

-

Last visited

-

Days Won

175

Content Type

Profiles

Forums

Events

Everything posted by VPI

-

Sexy as fuck.

-

Thanks Al. It is a pretty clunky design as designing angular furniture is not my forte, but it will hold a drink without dumping it in my lap, so I consider it a win.

-

Loose Dry fit for the Ipe/Sapele cocktail table. Hopefully it will get warm enough at some point in the shop to actually finish it.

-

Soooo, ended up ignoring all of Steve’s advice and got the 10 gallon California Air Tools without the automatic drain valve. They only make the Aluminum tank up to 10 gallons and I decided I would live with the tiny tank as I wanted Aluminum and saw some reviews that showed even with continuous blow gun use the tank never really drops below 60psi. Good enough. Also read about the auto drain and saw it only works when the compressor is running so with the amount of use I would have, I would almost never be running it enough daily to start the auto thingee so would need to drain after each use anyway. Maybe I am reading it wrong but everything I saw said it only works for heavy users.

-

Also, YouTube build video or didn’t happen…

-

Pics or it didn’t happen…

-

That thing looks too hugeish for the tiny shop. Probably more of a shitty little two stage simple system, since I do not use any tools with the compressor.

-

Looks like you can add the auto drain to any of them but trying to determine if the air dryer is worthwhile or just do an aftermarket system.

-

So which is the HC approved model? They have a billion but I am thinking 10-20 gallons with an aluminum tank. Not sure about auto drain.

-

Went big with the first Ipe project and made some beefy coasters. That shit gives off some crazy neon greenish yellow sawdust that is kind of creepy.

-

They are on the list. Seeing a lot of reviews of the Kobalt quiet compressor as well, which comes with a longer warranty, but may not be built as well to begin with.

-

Makita tool has been there for 6 years. Reel is the new thing as I ponder what kind of wild air compressor I need to blow dust off of wood after sanding and CNC’ing.

-

Looking to set the record for largest, most expensive reel connected to the tiniest most shitty air compressor. I know the air compressor is not connected yet, for those people assuming I did it wrong.

-

Contemplating just going with something like this for the outdoor furniture. https://www.ipeclip.com/ipe-clip-standard-hardwood-fastener

-

All nails, all day at Half-Assed Woodworking.

-

Picked up over 600 bf of 5/4 Ipe this evening, mostly 20’ x 6” deck boards. Rich neighbor gave me a deal I could not pass up so I will have to find some way to use it. First, cocktail tables and Adirondacks for the fire pit area.

-

Yeah, kind of a small surface practice to figure out how to do this across an 8’ dresser next.

-

The plywood walnut definitely has more of a red tone than the solid walnut; but then again, the drawer fronts do not really match the top so not too big of a deal. The dog supply cabinet is as far as I can get it now without decisions on drawer pulls.

-

The deals can be great. My main problem is I now have Milwaukee 18v and 12v and Dewalt 20v and 60v tools. Any expert advice on finishing an A1 grade Walnut ply? Built the cabinet out of plywood and the legs, drawer fronts and top out of real sticks.

-

Had to take advantage of the buy two batteries for $199 get a free $229 router that Dewalt is doing now.

-

For those non-Dougs that resort to the lowly pocket screw, the Dewalt trays on sale at HD do fit perfectly to get all the individual packages out of the drawer.

-

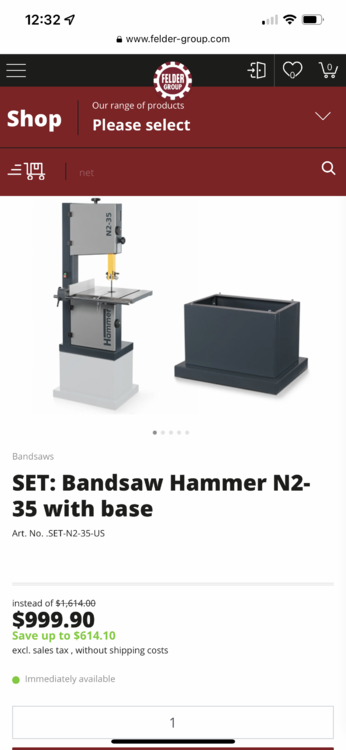

Felder has a hell of a deal on the N2-35 bandsaw. If I could come up with the room I might add it to the collection to have a resaw bandsaw and a curvy bandsaw. Bandsaw with base for $999, or without base for $1350????

-

What thickness do you use for coasters? I need to make some for the outside tables and need them to be substantial enough not to cup, if possible. Also, finished the awful finishing process. I need to just spray everything. Brushing sucks.

-

Was able to nail together the ottoman for the lounge chair setup out front. My Total Boat Wood Sealer I used on the chair has gelled up on me so I tried to thin it down as the stuff is out of stock everywhere. Hopefully it behaves in it thickish oil current format.

-

No snipe whatsoever as it jumps when it comes off the out feed roller, well past the cutter head. The rear rollers were off a bit (low) so they are set now to .020” below the cutterhead and the chip breaker was down .015” (supposed to be .040” from the cutterhead so I am hoping those combined were creating the weirdness. If that doesn’t work I am going to lower the spring tension on the feed rollers or drop the table rollers.