-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Shawn

-

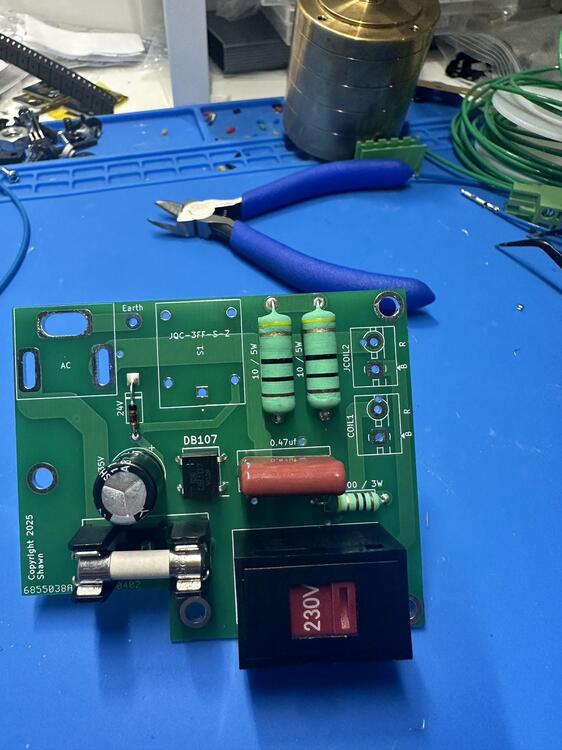

Making a soft starter module with switchable voltage function. No screws required if attached to the AC socket directly.

-

So complicated. Like the volume mute function.

-

Yes. The machine is from Snapmaker, and I am planning to get the Langmuir. Links here. https://www.snapmaker.com/en-US https://www.langmuirsystems.com/mr1

-

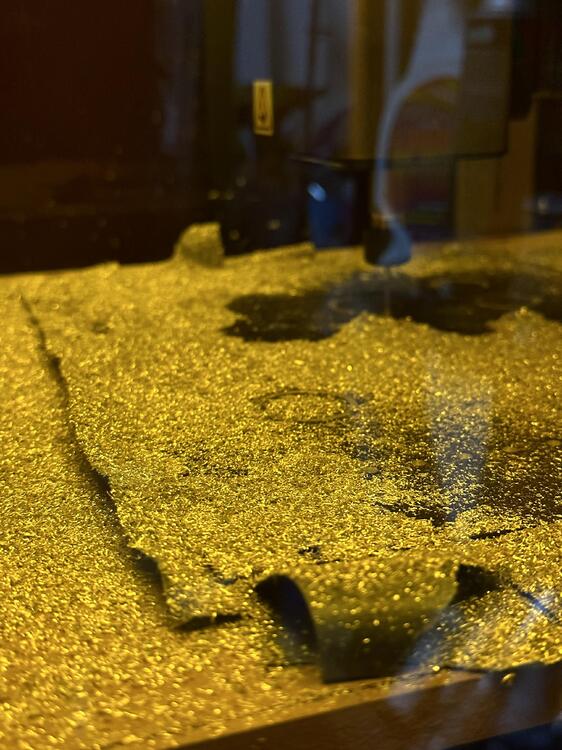

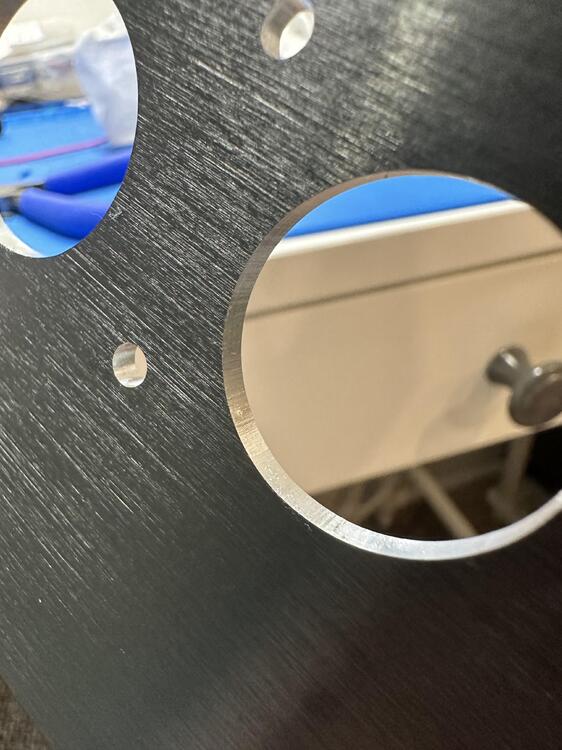

Okay, two months since my last post -time to dive deeper into the enclosure. I spent the past two weeks designing, ordering materials, and milling all the necessary holes. After breaking two milling bits in the process, here’s the result! The upper panel features over 30 screw holes for the amp boards and power supply. The transformer is planned to be mounted in the center using an M8 bolt, along with an isolated cover. Most of the screw holes are chamfered (using a chamfer milling bit). The square holes are designed for the transformer wires to pass through. The tapping work was manually done. Here’s the hole for the volume pot. The pot can be installed upside down to provide more clearance. I used an end milling bit, which resulted in this textured finish. The side panel will house the 10M90S without heatsinks. The plan is to transfer the heat directly to the enclosure. The enclosure dimensions are 430 x 80 x 330mm with an 8mm thickness. Two XLR input holes. Hole for the EMI AC inlet socket. I’ve realized that I might need a more professional CNC milling machine, but my garage just doesn’t have the space for such a large machine. Milling is really fun and incredibly satisfying.😆 How about going even further next, let`s say a fully CNC block enclosure (I am planning it right now).

-

Okay. After multiple checks for the occasional humming issues for a week. I finally learned the lessons. Separate each channel into individual space connectors. The two EL34 heater cables can`t go through the same connector(or be too close). The two 460V rails may have interference with each other, but I don`t have the knowledge to explain it.

-

Edited and fixed.🤞 I will work on the CNC enclosures next week. The drilling hole patterns will match any layout versions from .2~0.23. Just send the Gerber to the factory, Can`t wait to listen to it.

-

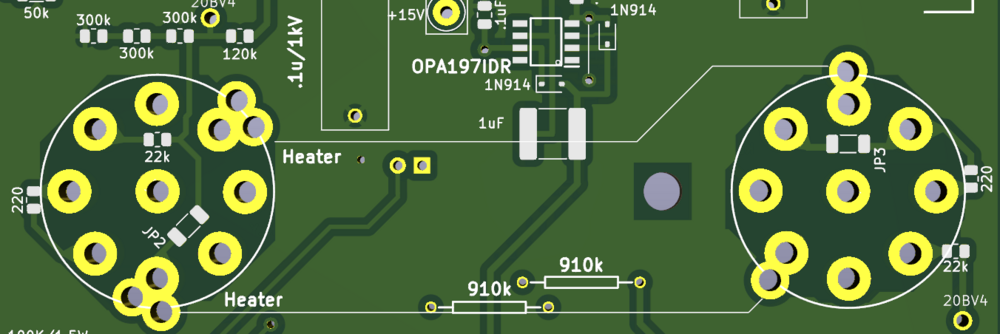

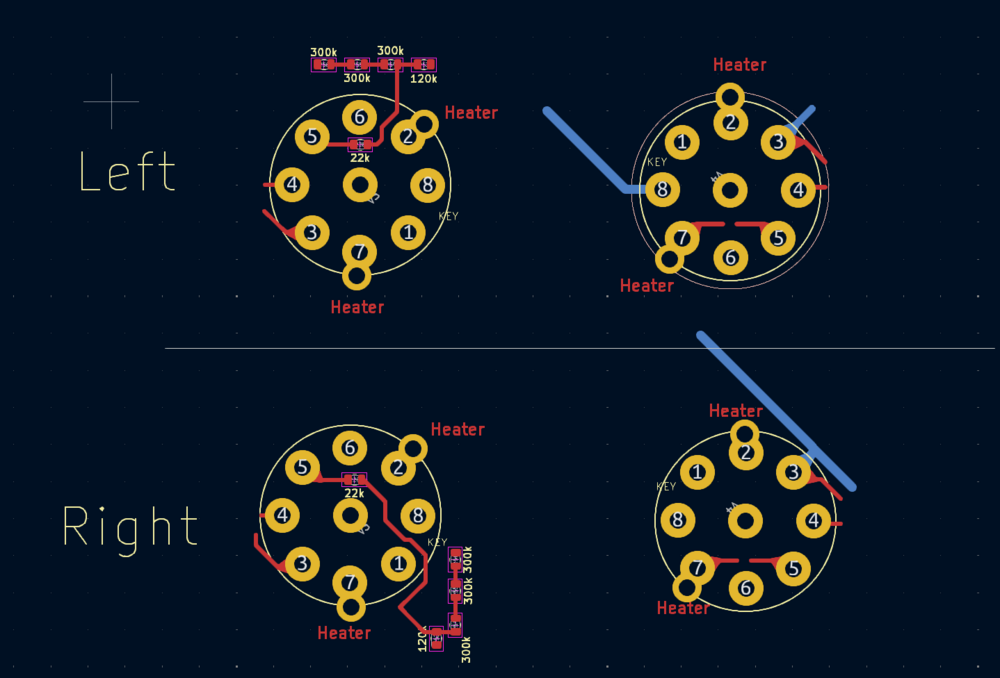

Done. Credit to JoaMat. Instruction again for 20B-V4 each channel: 1. Remove JP1~JP3(JP1 on the back which is connect Pin 1 & 3). 2. Remove two 220 ohms resistors. 3. Remove the right-hand side 22k ohms resistor. 4. Wiring the two pads which are marked as 20BV4. 5. Separate heater power supply. Based on layout ver.23. Hope this instruction can help someone keep investing in their mini T2.😊

-

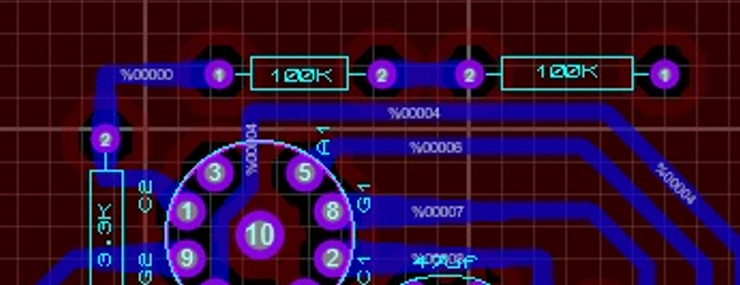

Here is the draft based on your description. Regarding No.5, Should I pull the right-hand side(picture below) Pin5(G1) also to the resistor string between 120K and 300K resistors? Also Could you double check if there is anything I missed? Ignored the blue traces that go to KSC2690A and O-. I will be working on the new layout after making sure it is correct. You know what? You are at another level of speed. I was thinking about your description and gonna say the zero jumper is the solution and you did it!

-

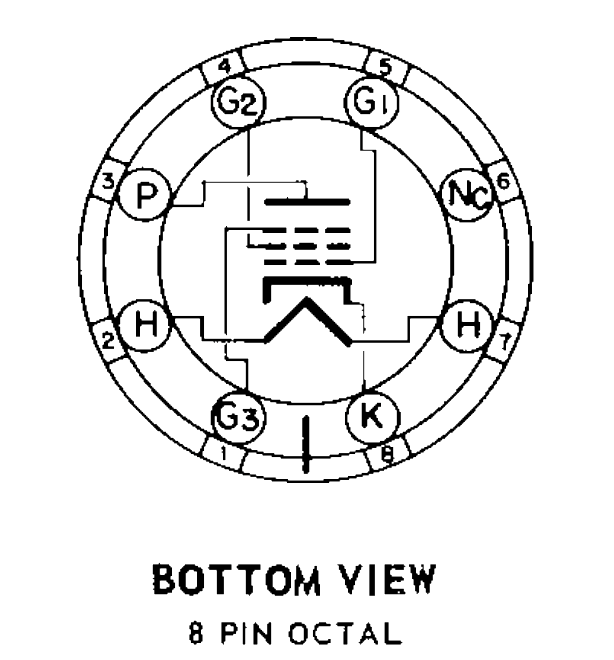

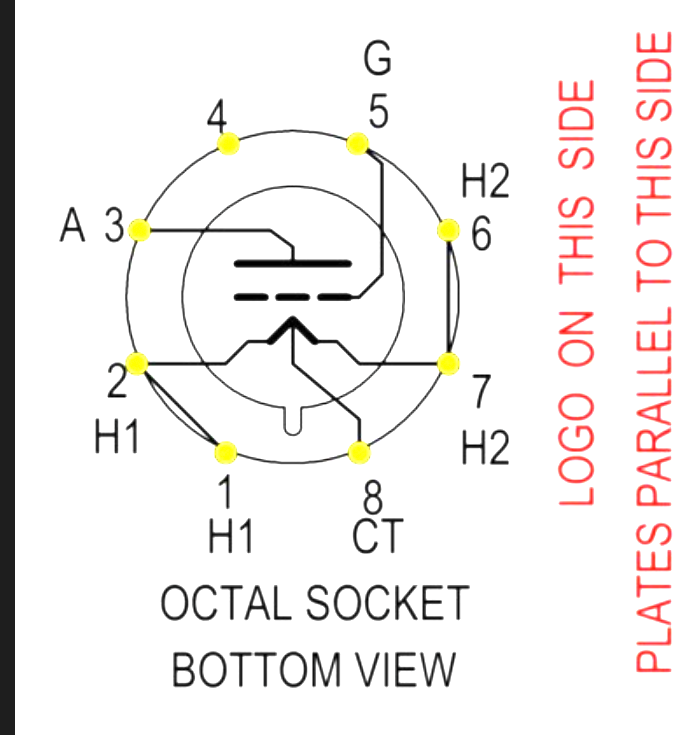

The size is impressively small. What is the heat generation of it? Excuse me for one more question, JoaMat. Here are the socket views of 6CA7 and 20B-V4. To convert the 6CA7 to 20B-V4: 1. Pins 1 & 2, Pins 6 & 7 will be supplied by 5VDC instead of 6.3VAC. 2. Each 20B-V4 needs to be powered by separate supplies. 3. The Pin 8 which is CT on 20B-V4 remains the same since it's the Cathode on DHT. 4. Disconnect Pin 4 Please correct me if I'm wrong. Don`t really want to massive and fry those expensive tubes. Don`t know what to do with Pin1(G3). And there is a 220Ohms resistor between Pin 3&4 and 22KOhms between Pin 2&5, Do I need to change it?

-

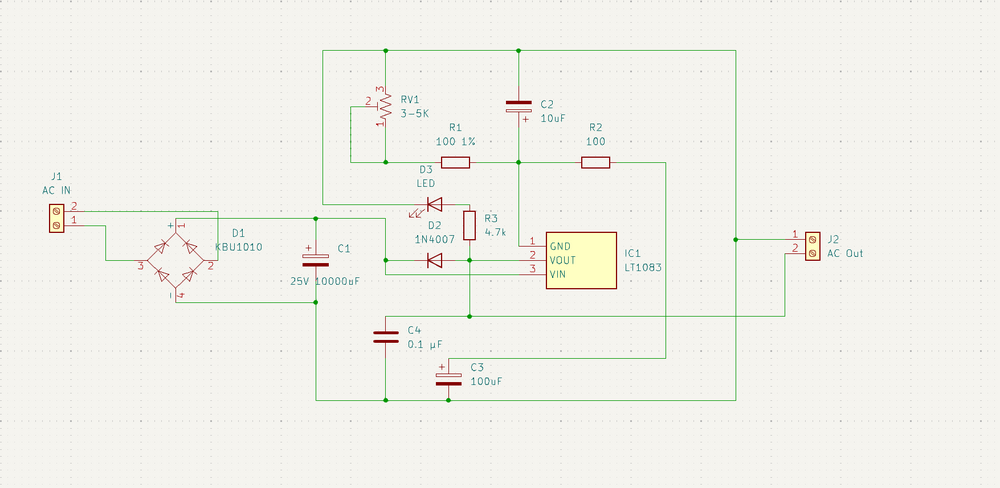

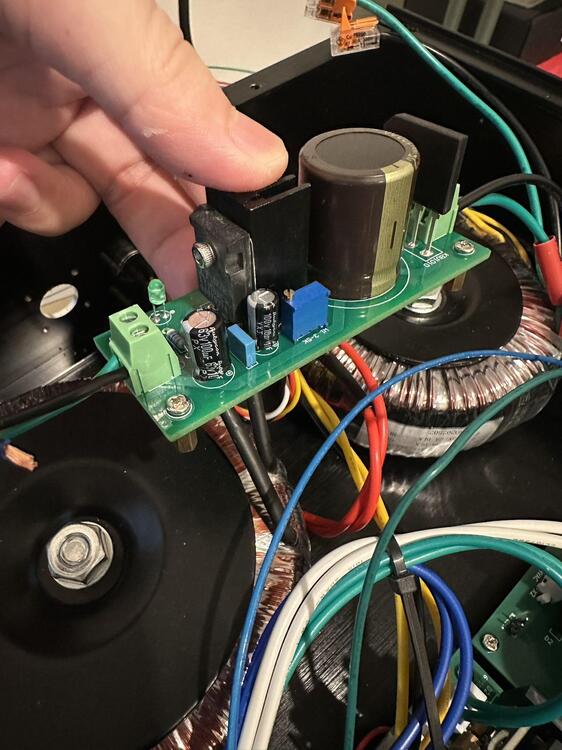

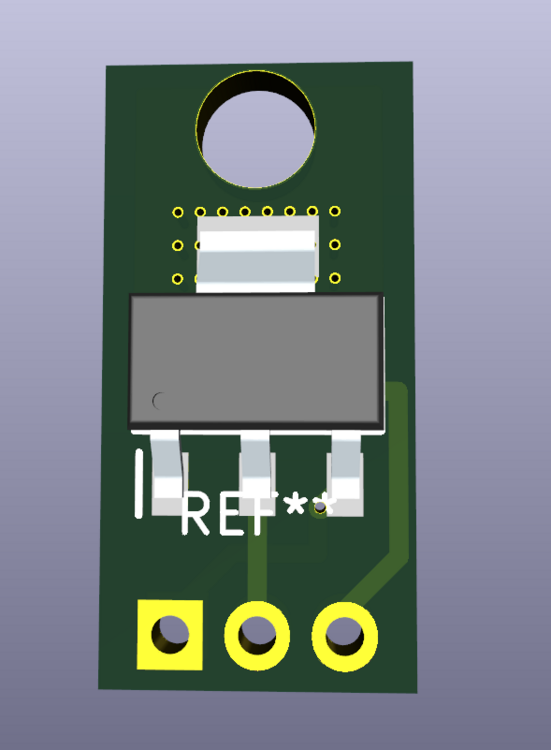

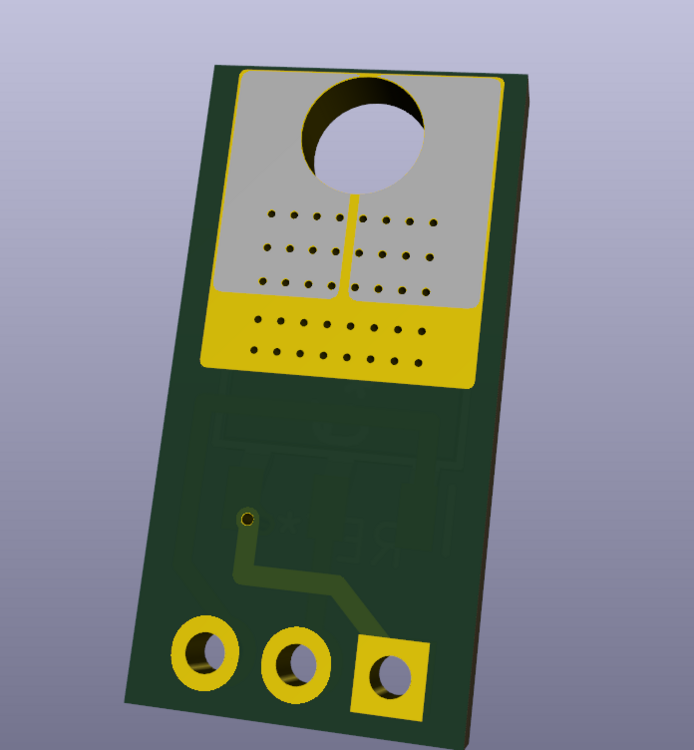

Not original from me. I found it on Alibaba and made some changes to it. Here is the schematic I drew it under 10 mins. Well... not perfect but readable. The size is 96mm*35mm. Still can shrink it down by removing the heatsink and attaching it to the chassis. What is the size of your DC-DC converter? And your pics remind me I have a bunch of 20B-V4 sitting in my garage for yrs. How do you convert the circuit to adapt 20B-V4?😳 AC Out should be DC Out.

-

Thank you so much for sharing the pictures. After checking everything, I dont have any mismatches. BTW there is a wire cut in your back here but I believe it's the software problem. I still have space for two regs in the PSU case. Mounting the LT1083 to the case maybe a good idea to shrink the board even smaller. I noticed the time for balance to be stable became longer when you used DC heaters.

-

I have the same issues with OP27. The OPA197 seems to be more reliable but still has a chance of going wrong. According to my experience, those circumstances may be relative to falling: 1. Kerry Design PSU with HV delay On. The +220V will keep at ~+20V and get back to +220V after 40 secs. In this case, it may somehow overload the offset servo for a while. 2. If the three high-volt sources are not engaged at the same time. I forgot to plug in +220V, after plugging it in, it burned my OPA197. 3. Switch off the amp and turn it on immediately. It happened to me once. I lack the knowledge to analyze the falling but those are my experiences after burning a couple of the OP27s and OPA197. The OPA197 has a higher tolerance of supply voltage(36V) with protection. After a few hrs troubleshooting the left channel humming issue, it seems like it is relative to the left heater wire of EL34, When I touched and wiggled it, the humming tone changed. I guess the parasitic capacitance changed when I touched it but not sure since the other channel is totally fine without the humming issue. The two pairs of heater wires came from the same space connector with different windings. Don`t know if it is bad grounding or not.☹️ In this way, I made this(attached below), and it somehow fixed my problem. LT1083( 7.5A Max output at 5V) since I have it on hand. The good thing is the voltage drop is 1V which means the 6.3VAC can be accepted as input without any problems. The bad news is the heatsink is super hot and I have to redo the layout and get the larger heatsink instead. Still don`t know how the heater AC Coupled to Signal circuit.😑 Joatmat, Can you take a screenshot or photos of the empty left channel board(Front and Back) by any chance? There may be something wrong with my board layout.

-

One of my OPA197 had a sparking firework show and died today. It happened when I switched on and off, then on the amp quickly. I guess it is the ripple current or something which turns out the mandatory of a soft starter. Fortunately, I have a bunch of OPA197 in my hand. Swapped and got it back. The other thing I realized is that I have trouble with the tiny humming in my left channel. The grounding is probably bad since when my hand gets close to the left EL34, I do not even touch it, and the humming reduces and disappears. Any ideas?

-

How about something like this with the aluminum oxide isolation pad + screw insulator. It can be mounted just like the KSA1156 to the L-bracket or straight to the enclosure.

-

You may need this for stn9360 plus the aluminum or copper board. https://www.fischerelektronik.com/web_fischer/en_GB/heatsinks/C04/Heatsinks for D PAK and others/$catalogue/fischerData/PG/FK256/search.xhtml The KSA1156 is abandoned by Mouser. But other suppliers still have some in stock. IXTP01N100D is out of stock as well.☹️ 2SC3324 can be replaced by 2SC2713 with higher noise as a compromise.

-

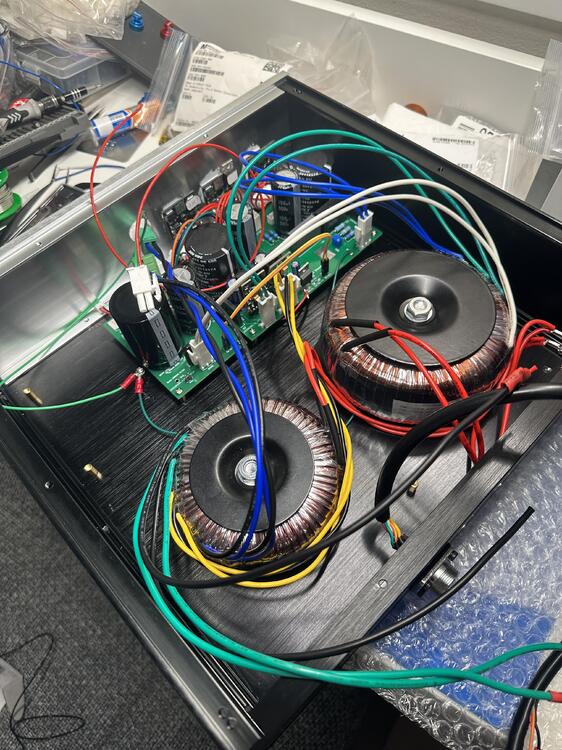

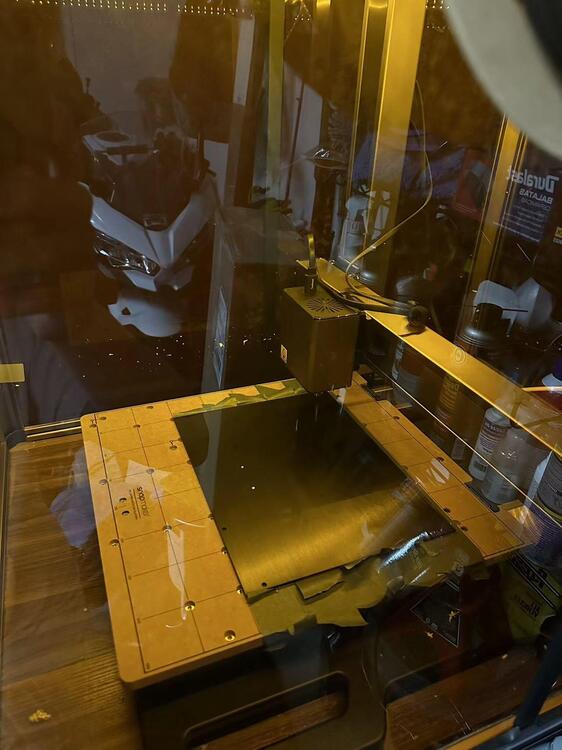

Here is a long post I wrote, but may have a little help to someone who tries to build the T2 mini by JoaMat. Transformer Specifications: There are two transformers in total. Primary: 120V(USA or other countries like 230V) Secondary: 320V 0.25A 365V 0.25A 190V 0.25A 16-0-16V 0.5A 6.3V 4A × 2 6.3V 2A × 2 I highly recommend adding a soft-start circuit because the inrush current generated by the transformers is significant. High inrush current can easily blow the fuse and cause long-term stress on the filter capacitors. If a soft-start circuit is not added, a high-current fuse will be required, but that would compromise the protective function of the fuse. Chassis: I housed the power supply and amplifier in two separate chassis. For the PSU section, I used Kerry-designed GRHV and GRLV. Pay attention to the chassis height clearance to ensure it can accommodate the transformers. The specific drilling hole specifications can be found in the current thread—I recall JoaMat mentioned them somewhere. All panel holes were made using a desktop CNC router. I believe it's a good investment to have a desktop CNC router, as it ensures precise hole dimensions. The text and graphics on the panels were also laser-engraved using the same machine. Watching the CNC mill parts is quite satisfying. Power Supply: Three different high-voltage power sources are required: -460V, +400V, +220V ±15V for the servo For details on Kerry Design’s GRHV/GRLV, refer to this link: GoldenReference Low Voltage Power Supply Two mainboards are required—one for -460V and +400V, and another for +220V, leaving the rest of the board empty. To save space, I designed a new PCB specifically for the +220V rail. Notes: If using Kerry Design’s GRHV/GRLV, I suggest disabling the high-voltage delay function. In my tests, the 220V rail initially outputs only 20V, while the 460V and 400V rails start around 200-300V before reaching their nominal voltages after approximately 37 seconds (time varies based on capacitor size). Although this delay is short, it prevents the servo from functioning correctly. During this period, the balanced voltage remains around 200V, which could be harmful to headphones over time. A better solution is to add a dedicated tube warm-up circuit. Output voltages may have minor deviations. For instance, the actual 220V rail might measure around 217V. Even with 0.1% tolerance resistors, small variations can be amplified. A good approach is to use a trimmer resistor—for example, replacing a 20kΩ resistor with an 18kΩ resistor in series with a 2kΩ trimmer. Amplifier Assembly: SMD components should be installed first, followed by through-hole components and tube sockets. To simplify the process, I used a paste stencil and a heating plate, which significantly saves time. For the other side, I used a syringe and a heat gun. A more efficient method would be using a heating plate for both sides, with two different solder pastes. For example, using 183°C solder paste for one side and 138°C solder paste for the other. Notes: Don’t forget to connect the +15V jumper and the servo jumper. Otherwise, the balanced voltage may stay at 400V, potentially damaging the servo. This damage may not be immediately obvious, but you might notice the servo stabilizing more slowly, tiny background noise, or excessive sensitivity of the EL34 filament power supply to external interference, leading to noticeable microphonic effects. The T2 Mini’s heat dissipation is moderate, somewhere between the Grounded Grid and KGSSHV. If your enclosure is large enough (not wooden), power transistors like KSA1156 can be directly mounted to the chassis. However, a better approach is to use an L-bracket mounted to a heatsink. My enclosure measures 300mm × 297mm × 62mm, resulting in an internal temperature of around 45°C. Do not use this approach for KGSSHV, as SiCFETs generate a significant amount of heat. 01N100D must be properly insulated. Use single-point grounding as much as possible to avoid ground loops. If using aviation connectors, ensure they are rated for at least 500V. HN4C51J and HN4A51J look very similar—don’t mix them up. Ensure correct polarity for LEDs and 1N914 diodes. Test all components before powering on to verify continuity and check for shorts. For EL34 filament wiring, use at least 18AWG wire. One Last thing: Enjoy the build🙃

-

The STN9360 has no problem in megatron build. Make sure to check the pin out as I remember that the adapter board needed to be rotated back.

-

The picture is from your earlier post. I will go through other files to check for any errors this weekend. Congrats for your new driving toy. I remember the Z06 comes with a flat-crank engine which sounds insane. Does it have bucket seats?😍

-

Based on the megatronxl layout, the second 100k resistor on the top left is float, any reasons for that? And what is the purpose of those 10K trimmers? I assume they are for grid bias.

-

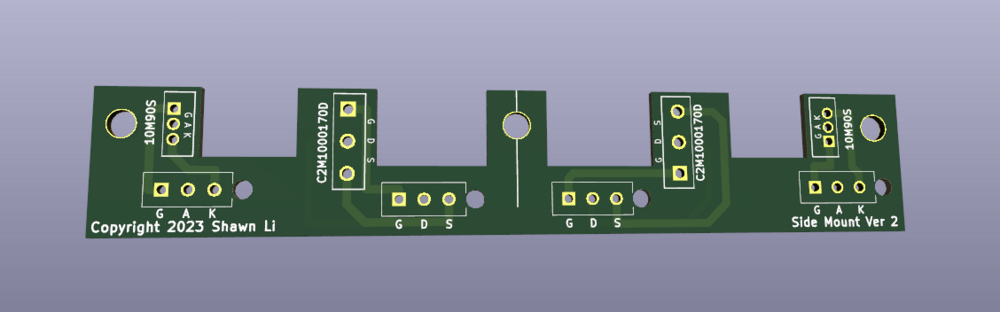

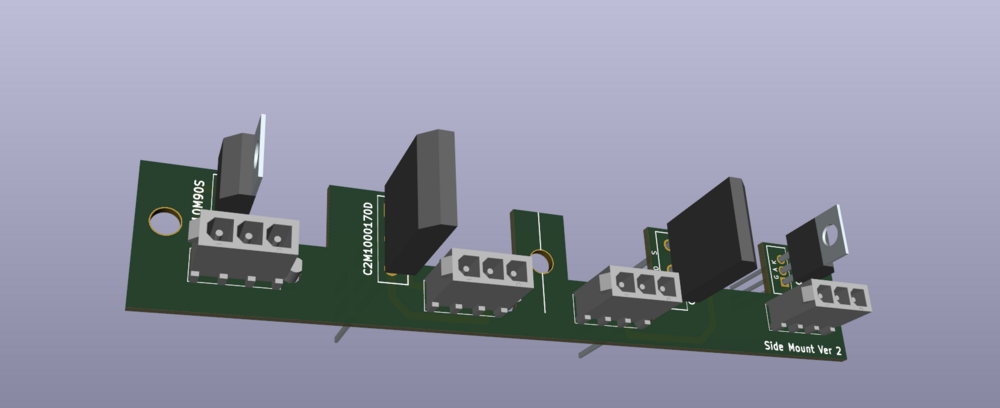

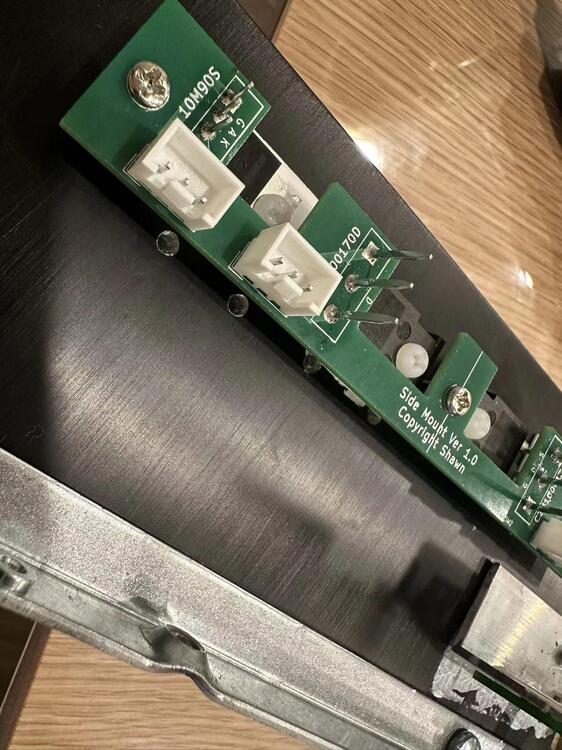

Another KGGG alive. I separated the GR power supply and the GG amp into two chassis, making it easy to reuse the GR power supply for the next project. The four holes with the rubber blocker on top of the amp are for balance and offset adjustment. I made a side mount board for the 10M90S instead of using the L bracket. The side mount board is attached if someone is interested in it. It is a 450V version, The tail resistor near the offset pot is 200ohms to track the offset voltages down to 0. To make the servo work, offset voltages must be higher than 15v. The power supply comes with a soft starter of about 50s. I don`t want to talk more about the sound since many comments were mentioned. Pretty decent with my Omega and 009. Thank Kevin Gilmore for bringing the project to the table. SideMountV3.zip

-

CNC metal machinists (for Stax amp cases) unite?

Shawn replied to jamesmking's topic in Do It Yourself

Another option for the desktop CNC machine that I purchased from Snapmaker works as well. The working space makes it easy to fit the whole chassis unit with the enclosed cover. It has two different laser modules that work perfectly for engraving. I have some pics shown while I was working on the GG upper and front panels. Milling the holes for tubes, Stax jack, and screws. I settled the speed to 100mm/min and 0.1mm step which gave me the balance of speed and a nice outcome. The bit is from Datron, 3mm Single Flute End Mill. I have another 2mm ball end bit from Snapmaker which I also used for milling the M2-size screw holes. The only complaint about it is the limited 200W CNC power which does not allow the drilling process. The 8nm laser module is the most satisfying. Easy to manage and nice outcome for the front and back panels engraving. -

-

-

and now for something completely different part 3

Shawn replied to kevin gilmore's topic in Do It Yourself

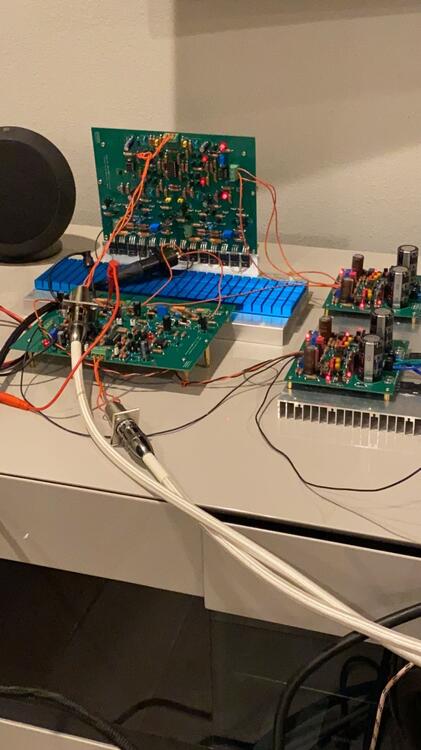

I just completed it last week by setting it to ZF and 100ma bias ( +-20V rail). Still waiting the chassis and soft starter. Sounds better than my dynalo\hi with my HD800 and K1000. -

and now for something completely different part 3

Shawn replied to kevin gilmore's topic in Do It Yourself

Thx for the suggestion. Seems like I real need a softstart borad to built.