jamesmking

High Rollers-

Posts

406 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by jamesmking

-

C2M1000170D has just become available again from radio spares. if you want to avoid mouser (currently out of stock anyway) or digikeys current pricing gouging of $9+ EACH. In radio spares select production pack not standard pack to see 1213 in stock minimum purchase 5 the price is still more than pre-silicon shortage levels but is low compared to other sellers.

-

unfortunately now mouser, farnell and digikey now have the FQPF8N80C as obsolete and no longer manufactured...

-

Want to build a balanced dac. dont know where to start

jamesmking replied to BadgerMcBadger's topic in Do It Yourself

0. lose your conscience 1. get an oem to make the thing for you (cheap as possible no need for quality/performance) 2. attach pointless bling to the oem thing (if you are out of ideas for bling try a university art department, get the students to do it as a project for zero cost. Offer the students a 10% discount on the final product as an incentive) 3. get a e commerce web site (students studying computer science should be able to make it for you again offer 10% discount) 4. bribe some reviewers (give them the product so they can give it to their mistresses) 5. get lots of media exposure (talk BS about your innovative product) 6. create a cult following (amongst the rich and famous. limited editions, special one offs etc) 7. sit back and watch the money roll in.... (get a swiss or caiman islands bank account) 8. get a good accountant and avoid all taxes 9. get your product ridiculed on head-case (who cares your are now a millionaire) 10. go back to step 1 when sales of your current product start to drop 11. if income still falls make a NFT version 12 if NTF does not make enough money invest in bit coin, lose all you money and go back to step 1 I hope this plan is detailed enough for you.... 🙂 -

I'm tempted, it must be decades since I went to a hifi show of any sort. But I'm not sure of the point i am very happy with my mostly modern t2 and sr007 combination....

-

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

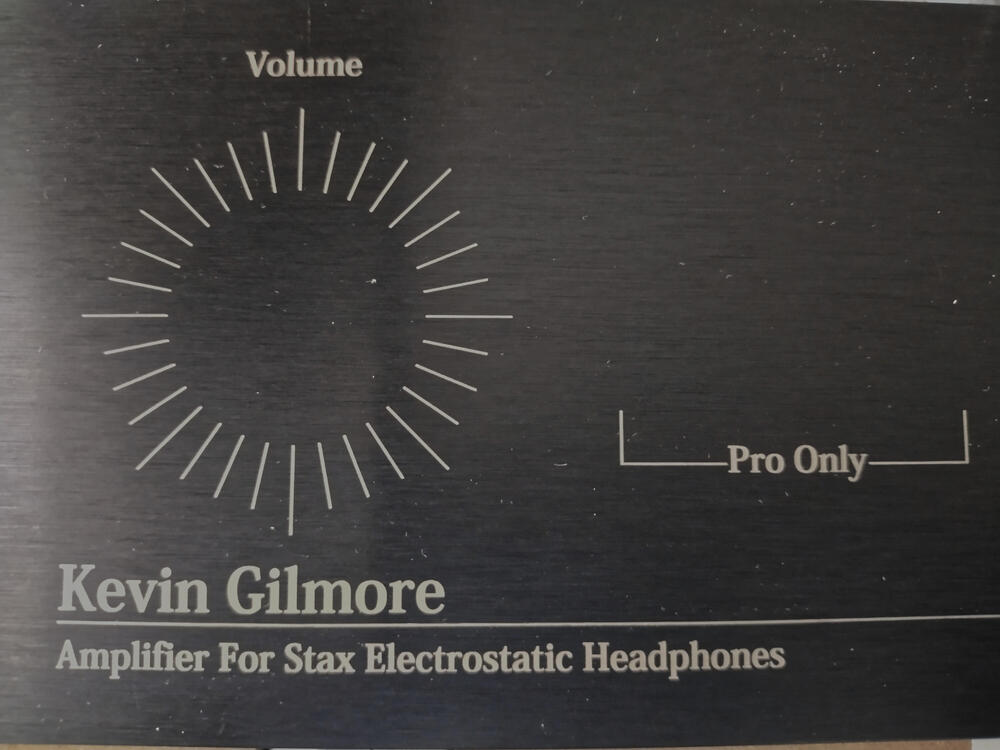

well the missing bolts arrived and the free 20W laser... so I had some fun trying to burn front panel markings. After a few experiments I realised the default settings in light burn are insane...6000mm/min movement speed no way! and 0.1mm between steps does not provide good resolution and gives a streak effect on text and slightly jagged lines... I improved by changing the settings to two passes at 90% power, 0.05mm stepover and 1000mm/min. This gives a crisp result (crisper than my camera phone can show). The result is not a shiny as engraving with an actual 10degree 0.1mm engraving tool, so I will experiment a bit more. I guess I am still not quite getting all the way through the anodizing. -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

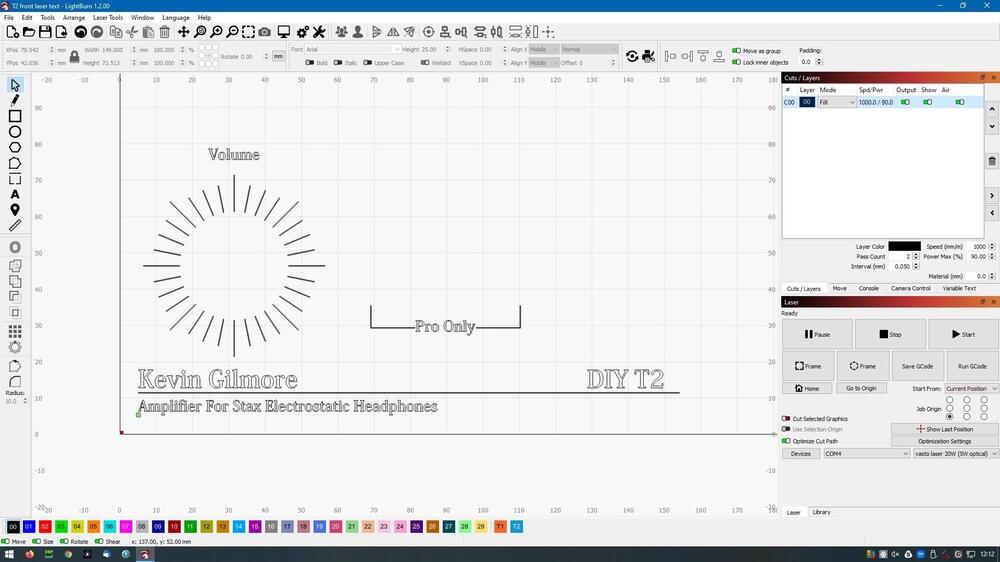

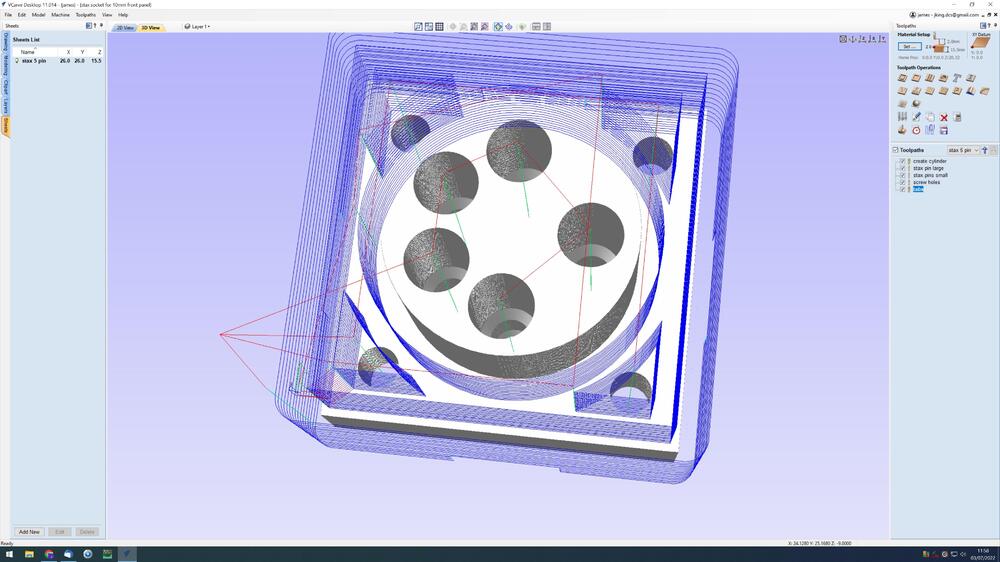

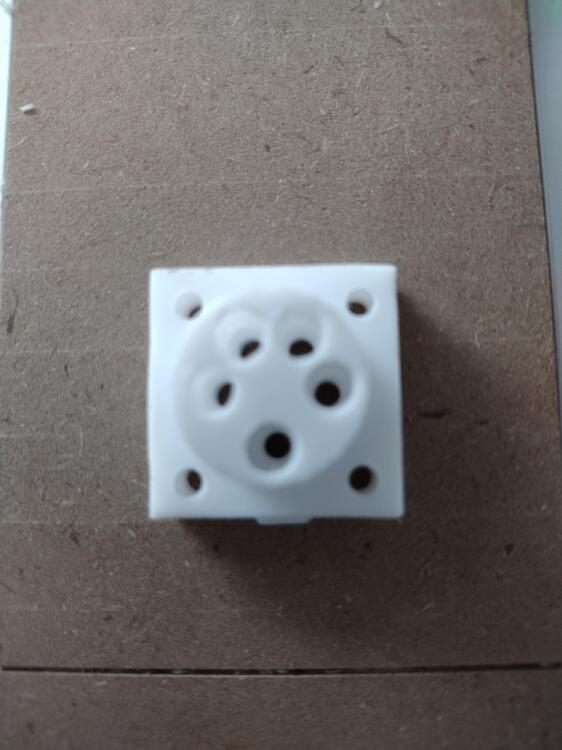

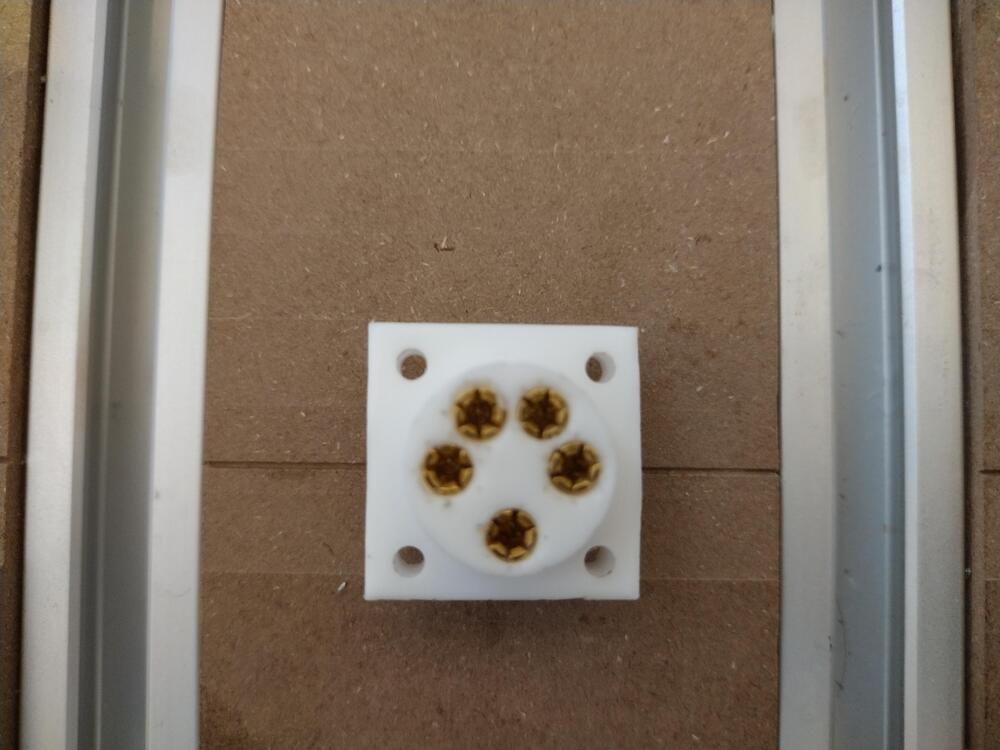

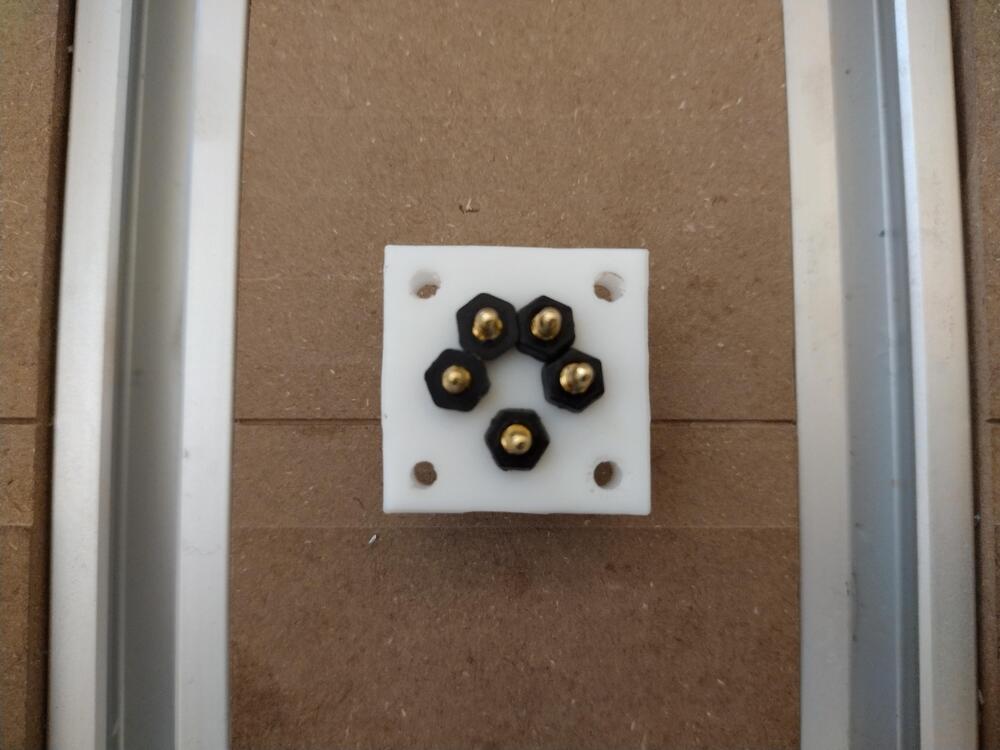

I got bored waiting for the replacement bolts to arrive and so purchased my own and finished installing the missing bolts. Here is my first CNC project: Making my own Stax 5 pin sockets using ptfe design in vectric vcarve desktop: making some (ptfe) chips and no router bits broken... final result after deburring and running the drill holes all the way through: overall I am happy with the result. The tabs holding the piece into the material could have been smaller and after test fitting the pins the holes should have been 4.6mm rather than 4.5mm but I don't have a 4.6mm drill yet. other than that I have a working Stax socket 🙂 This first version uses 3 tools: 3.175mm end mill, 3mm drill and 4.5mm drill.... its slow and boring changing tools, so I remade the tool paths only using a 3.175mm end mill, ran the code and found the drill holes were smaller than expected. I measured the 3.175mm end mill... 3.13mm... hmm... so I updated the tool data base with the correct diameter and re-ran the cut again.... I realise now I have to measure all my tools and not rely on the size they claim. I could not find any metal m3 nuts that fit the threads but are small enough not to touch each other so I used nylon nuts instead. I tested the insulation between the closest pins pairs to each other and got 300Gohm at 5.5Kv. -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

on further inspection the clamps held the work down ok, but the table is bowed downwards in the middle, hence the vibrations in mid way. I will experiment with the tape and ca glue. I also have purchased a thick spoil board which I will attach very firmly to the bed and level that. But I don't see much point in doing the levelling until I have put in the missing bolts which I cant do without some disassembly anyway. I also need to square the Y axis (dual motor) and square the spindle... all the axis come pre assembled - no bolts missing there and I did check all the bolts were tight. almost all the missing bolts are to things like limit switches, drag chain rails, thin guards to stop chips jumping onto the axis threads, bolts for the additional spindle holders etc. I would not run the machine if it did not feel the structural parts were not well bolted together. I could stop all the vibrations by putting weight into the middle of the work piece. The machine (other than the standard spoil board) feels really solid. the laser should arrive in 2 weeks or so. I hope 20W will be powerful enough, but its a free gift from foxalien for the missing bolts and scratches to the controller box.... I don't mind taking things slowly including the speeds and feeds i'm in no hurry - I have a lot of learning to do and a lot of experience to get. I know i'm going to break bits, ruin some work etc.. and im ok with that, hence the cheap bits and working a scrap materials. I was fascinated by wood work and metal work when at secondary school but I ended up studying computer science and university. I like the idea of making things, (I guess it was having lots of lego when I was a child) - and like the idea of making better looking front, top and back panels for my stax amps, so i'm viewing the entire thing as a learning experience a to keep me occupied now I have built all the stax amplifiers I wanted to. -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

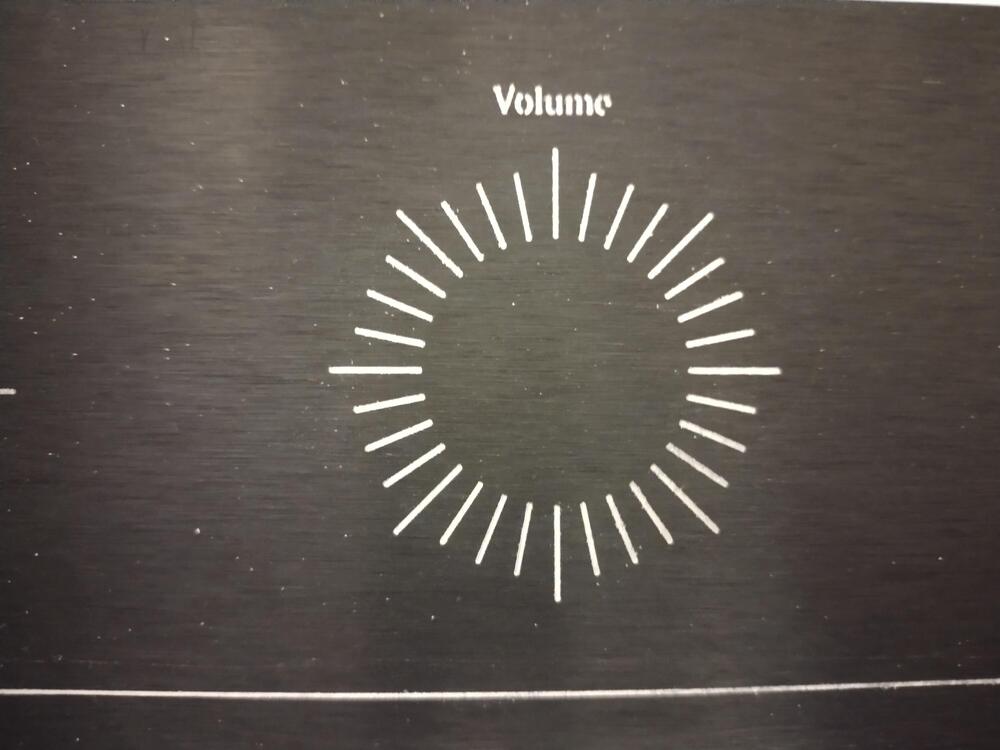

Thank you for the advice and support Kerry, I suspect the chineseium 2mm end mill is the problem.... rather than single flute it has lots of little burs on it and was garbage at clearing chips and sounded like shit at 10mm min cutting speed. I'm hoping single flute will be better. I have some single flute chinesium 3mm end mills and 6mm but I have not been brave enough to try them yet. Once I have got some experience I will get some good quality mills. I tried some engraving with a 30degree 0.2mm chinesium engraving bit and this worked much better no breakages and a lot nicer cutting sounds. I did some rate tests and got up to 160mm 0.022mm depth of cut without breaking anything. I found the line quality slightly degrades as the cutting speed goes up so I settled on 100mm min. I have not tramed the mill yet or made a spoil board or levelled it so I was not expecting perfect results but the engraving is not bad. The lines are a little thick for my liking (I made them 0.4mm wide in the cad) but I managed to cut through the anodizing without an issue at 100mm per min and 0.022mm depth of cut. Part of the e is missing in the volume text, but the text is quite small (which I knew would happen from the cutting simulation. I need a smaller angle engraving tool for the fine detail on the e, so I have ordered some 10degree 0.1mm engraving tools which the simulation shows will fill out the entire e). (sorry its slightly blurry just used my cheap phone could not be bothered to go slr and tripod) For software I tried fusion360 - gui and user experience is diabolical as a lecturer I can get it for free but I hated it. I settled on paying for vcarve desktop - it does what I want, is easy to use - I just wish it had adaptive tool paths. For sender software i'm using candle although I will probably go universal gcode sender. I just tried 3.175mm single flute end mill and got chatter and lots of vibration of the aluminium I was cutting when going above 0.1mm DOC at 250mm/min. I suspect this is because: 1. I have not levelled the supplied spoil board, 2 I only used 4 hold cheap down clamps (material 430mm long, 90mm deep and 10mm thick) and I think painters tape + superglue might be better, 3 my machine is missing half the bolts. (carton containing all the bolts and washers split open in shipping and about half of everything must have fallen out of the box on route) 😞 On the other hand I did not break the tool 🙂 So I'm pausing experimentation until the rest of the bolts and a thicker spoil board arrive, then I can level and make more meaningful experiments... -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

Well I'm no longer a cnc virgin finished building the machine yesterday. Broke my first end mill today. 2mm carbide endmill trying to mill 27mm long ventilation slots in 3mm thick aluminium... first two slots went ok taking tiny nibbles at 0.2mm depth of cut and a feed slow increasing from between 10mm to 100mm per min. Then I got a little too ambitious with the feeds going for 200mm feed and 0.4 and then 0.6mm depth of cut. Instant SNAP I guess this is to be expected.... I did hear the sound of the cutting change a little before hand but did not react in time...Post mortem on the end mill shows it got clogged up... guess I need cutting fluid a single flute end mill and more experimentation... I literally had to use plyers to extract the broken end from the aluminium it got welded in. well just broke a second bit... 100mm feed 0.3 depth of cut is too much for the cheap chinesium 2mm endmill again the end mill bound and clogged up.... need to wait for some (hopefully better) single flute 2mm to arrive.... -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

a speed and feed calculator. https://fswizard.com/ -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

this stuff looks interesting Cermark Spray for making labels on steel, unfortunately does not work on aluminium- Starts at 25:32. marking aluminium with a lesser -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

A few useful basic CNC beginners videos I have found. calibrating axis setting up a spoil board. problem solving issues guide to bits some speeds and feeds for aluminium and steel - starting at 20min 20secs -

CNC metal machinists (for Stax amp cases) unite?

jamesmking replied to jamesmking's topic in Do It Yourself

Thank you Kerry. My plan, to begin with, is to modify existing hifi2000 cases and just cut holes for connectors and valve bases, do some engraving and more ventilation slots etc.. . I can't see myself scratch building a case any time soon, but I agree if I go down that route I will need more power and bigger tools. One thing that I am a little concerned about is the lack of software spindle speed control and I don't think there is a tachometer to tell you what the spindle speed actually is. But I guess I could get a hand held tach. I notice that most high power motors are water cooled. I wonder if I could use my pcs 480mm r(4x 120mm fans and 80mm thick) radiator 🙂 -

I could not help but notice that the dead tree carcass machinists have a thread on wood machining. But dead trees do not make the best cases for stax amplifiers. So i'm a little surprised that there is no thread dedicated to CNC machining metal. The motivation for this thread was that I turned 50 years old a few weeks ago and for my birthday I decided to buy myself a CNC machine so that I could make my own cases for my stax builds. I decided to buy the foxalien Vasto, https://www.foxalien.com/products/cnc-router-machine-vasto?sca_ref=725103.t6qfXeHAnx based on not much more than I needed to machine 400mm by 400mm and the reviews on youtube are very positive. I'm waiting for delivery so I can't comment on if it is any good and I am a complete CNC newbie so I'm hoping this thread might become popular and eventually contain some advice for people who want to build cases for their amps. regards and best wishes james

-

I have not ripped the telarc lps but I do have telarcs lps, cds and sacds issues of several classical recordings including the famous 1812 and the holst suites, Stravinsky firebird and pictures at an exhibition. I don't have a setup capable of playing back sacds without converting to pcm. I can bit for bit rip sacds. (hint early PlayStation 3 with early firmware could run alternative operating systems and could play sacds)... later firmware releases stopped this possibility and there is no way to downgrade after a firmware update. The telarc cd issues do suffer slightly from the down conversion... for example some of the cd issues do not use all 16 bits per sample. (My rme aes32e sound card has some analysis software and it shows the bottom 1 or 2 bits on some of the cd issues are not used and strangely the number of unused bits can vary between the channels!!). The sacd issues unfortunately do not give any details of how the conversion was preformed. Sound wise I find the lps more musical and a bit less muddled than the cds ripped to flac and played through my dcs elgar plus. However, there is not a lot in it and its possible that this is a limitation of the elgar plus - it was top end in its day but that was a loooong time ago. The sacd rips converted to 192K 24bit pcm do sound different to the cd, slightly less dynamic but more "cohesive" but this could be the effect of the dsd -> pcm conversion. Its also possible since the original recordings were 3 channel that they slightly tweaked the balance between the centre channel and the left and right to reinforce the centre a bit... Again the sacds don't give any details of any adjustments made to the mix... I have done transfers of my sheffield lab direct to disk lps - sheffield labs did release on them cd and I believe my recordings have better bass and more warmth and are more musical. The official issues do have a little more snap to plucked strings and possibly a bit better imaging. I run a highly modified garrard 401 with regenerative psu, upgraded bearings etc. But the official issue does have lower rumble than I can get from my garrard but the bass of the official issue is rather dry. If I run my recordings through izotope rx9 I can get rid of almost all the rumble and still sound better than the offical lp to cd transfers in the bass end. I suspect my cartridge is the limiting factor for the treble end. Running through the rme soundcards spectrum analyser I can see a fair mount of music above 20Khz in the lps which is cut off by the cd brick wall filter it looks like they did not low pass filter at 20k when doing the direct to disk. Extension past 20k varies from disk to disk - confederation does not have a lot, however the three Harry James lps have quite a bit due to the harmonics in the trumpets and brass instruments in general, cymbals etc. I am really sensitive to bass quality and I almost never play the official cds - I play my lp transfers. I also have also recorded some of my opus 3 lps and compared to dsd downloads available from dsdfile and in a few cases the offical opus 3 cd issue. (dsd file got the original master tapes and went direct to dsd) here my lp rip setup to the dcs 905 adc can't complete with dsdfiles' top end tape deck playing the original masters - the dsd macro dynamics are better, stereo imaging is better, treble extension is better and snappier, bass is deeper and more solid. Again there is some output above 20khz on the lps and dsd but it falls off above 20khz fairly rapidly which I guess is just the response of the analog tape deck used in the original recordings or possibly some mild low pass filtering. The potential problem with telarc sound stream onto dsd is, yes sacd has a higher sampling rate than cd but dsd has lots of high frequency noise which either need to be filtered on playback or "ignored" - if your playback system has little bandwidth above 20khz. Secondly you still have do do maths to convert from soundstream to dsd- the bit format for sacd and so will not give you a bit for bit copy of the original. I can't make a fair comparison of the cd vs lp vs dsd sound since my setup in London does not have native sacd support and so I reply on Jriver media player converting my sacd rips from dsd to 192K 24bit pcm. I do have a dsd capable dac - dcs elgar plus, but it can only do dsd via 3 bnc connectors and I dont have anything which can take sacd and provide that output (ironically my dcs 905 adc also supports recording dsd and has the same 3 bnc output). The rationale for sacd/1 bit recording was that you don't need to brick wall filter during recording and that its these filters that damage the sound. The filters cause phase shifts and also almost all symmetrical filters have pre ringing - i.e. echoes of the sample before the sample is played. However, with dsd you still need filtering on playback... In fact both the dcs elgar plus and dcs 905 adc have selectable filters for pcm and dsd for playback and record respectively. Considering non audiophile labels for example the Philips remasters of 1970s classical music - e.g. Marriners complete Mozart symphonies vs my lp transfers there is absolutely no contest. Many of the official cd transfers where from lp - if you spectrum analyse you can see low frequency warps and you can even hear the occasional click and pop of dust. The cd transfers from philips have awful treble, glassy, hard and "stringy" typical early cd sound - are lean, lack of bass almost no warmth. This is particularly bothersome with some of the early symphonies that are mostly just strings and the result is the cds are bit painful to listen to. My Lp rip vastly more musical and better balanced. Philips uncaring cd transfer vs careful lp transfer sound as different as stax sr407 vs sr007. I have not riped any of my lps to dsd for the simple reason I have no ability to edit the results without converting to 192K 24 bit pcm editing in pcm and converting back - which is not a bit accurate conversion... however unfortunately this is how many dsd recordings are edited. The dcs 905 also has the ability to do 384Khz but this outputs in a special format for a certain nagra digital recorder and I have not bothered to write any software to convert nagra 384K to pcm 384K although it should be possible and should be bit for bit accurate since the nagra simply spreads the stereo 384K over 4 192K channels as it does not have enough bandwidth to record 384K on two channels.... but I don't have a dac which can do 384K anyway. So for me, my general feeling is: well made original recordings on tape transferred expertly from the original masters to sacd or cd would require a ridiculously expensive lp setup to rival - definitely £20K+ for cartridge, arm, deck and phono stage even without factoring in the adc. Mass market classical cd issues of analog recordings different story.

-

the telarc recordings were half speed mastered with no transformers in the signal chain and a frequency response down to 12hz or so with no compression or limiting or any type. They tried to get the entire signal chain as high quality as possible and muck around as little as possible, right down to using only using 3 high performance microphones and not multi milking, spot lighting etc. They designed for proper hifis and not for the average consumer grade kit. The soundstream digital system also sampled at a higher frequency than the competition (or cd), and unlike early cds, telarc could actually do editing and splicing digitally whereas all the major record companies took the digital recorded it onto analog tapes edited the analog tapes and then played the edited tapes and digitally re-recorded (but still lied and claimed the signal chain was DDD throughout)... or recorded on their didital system and then converted to soundstream edited and then converted back. Even when DAT and proper computer editing took over the sample rate was higher than cd and had to be down converted and anti aliasing filters applied... the stream of data off cd also has a delay between the right and left channels. many early cd players did not correct for this which I think was one of the reason the treble was so sharp on the early cd players. A few high end players ended up having two dacs and a time delay circuit to realign the left and right channels. But I never got to hear one at the time. In many many cases the record companies transferred analog masters to DAT, and then threw away the analog master tapes... DAT had almost no error correction built in and a few years down the line the DAT tapes were unreadable and the master tapes were gone. So many of the cd reissues of classic analog recordings where actually digital recordings from the lps anyway, and the lp system they used for play back was garbage, the "remasters" sounded bad then and they still sound bad now. I could make far far better recordings from my lp system going through a dcs 905 adc at 24 bit 192Khz sample rate. Telarc digital on lp vs philips "remasters" of classical lps on cd... no contest. I played the telarc 1812 no issues on a decca black with decca pod, modified tie wire system and a proper line contact diamond. My ortofon cadenza bronze has no issues either and thats a moving coil. Both on a heavily tweaked haddock 242 unipivot arm. (ALL hadcock 228 arms had incorrect geometry and the aluminium arm tube versions lack the weight to properly press down on the inverted uni pivot)). And of course ALL telarc sound stream recordings have to be down sampled and anti aliased to go onto cd... The sound stream digital was far better sounding than the early Philips PCM - which DID NOT have even 16 bit resolution... it was about 12-14 bits + deliberately added noise because the 14 bits was not that linear and low level signals had about 25% - 75% distortion and looked like square waves.. apologises for incoherent rambling but for me the message from sound stream was make the record chain as good and simple as possible, make as few compromises as possible and don't muck up the sound with filtering or compression and aim for an audience with proper hifi... lessons many recording companies never learned and still need to learn today. I also wonder if the average person listening to music through their mobile phone gets higher auto quality than the average person in the 1960s or even 1950s... (when a good hifi seemed to be a part of most middle classes lives). I have listened to a friend playing some music through some cheap Bluetooth speakers via their mobile and I seriously wonder if (apart from the surface noise) the sound was better than a 1940s 78 on a good player. James

-

if you are using a multimeter with a 10Mohm input impedance then you will not measure the actual voltage. The stax bias output is very high impendence i.e. provides very very little current and so even the current draw of a 10Mohm multimeter will load down the bias and you will measure lower than expected. Either you need a meter with a Gohm or higher input impedance at 1000V or you need to measure before the current limiting system on the bias output. For example the golden reference HV power supply bias circuit has a 4.7Mohm current limit resistor just before the output so you need to measure before that limiting resistor and of course be careful because if you multimeter can't handle 580V or you touch the probes etc you will get a non-current limited 580V DC shock which is not going to be good for you. incidentally I get about 378V DC at the socket on my diy T2 (pro bias only) into a 10Mohm meter BUT this value is going to be very dependant upon the value of the current limit resistor in the bias circuit. So if you amps current limit resistor has a lower value then 420V is not necessarily unrealistic.

-

I dropped a valve on to a hard wooden floor and although it looked intact the insulation between the heating element and the cathode was damaged. (I checked it on a avo iv valve tester and it had <1Mohm insulation heater to cathode) it was even possible to see a little of the white insulation lose in the bottom of the valve. So this is one possibility.

-

Windows Drive Cloning Software

jamesmking replied to dsavitsk's topic in GoRedwings19's Computer Help Hotline

The user interface on macrium is not as intuitive or as pretty as acronis, and I cant cmopare the tech support because I never needed marcium support. My general feeling is that marcium is still a focused product. The only "security" thing Macrium does is that programs outside of macium cant delete or modify the back files you create with macrium.. which is sensible and ithis protection feature can be switched off. -

Windows Drive Cloning Software

jamesmking replied to dsavitsk's topic in GoRedwings19's Computer Help Hotline

I used to be a long time user of acronis true image more than ten years... I even was on their beta test program for a number of years. In my opinion acronis got worse and worse after about 2015/6 as a product and a company - I believe they got bough out by a venture capital company. Basic things were either removed or did not work e.g. you do differential backups. There was no way to delete a differentials from inside the program and if you deleted one from outside the program the index files messed up and you could literally get hundreds of error message popups one after another all saying could not find file x. The tech support in the forums basically stopped replying to peoples complaints - I must have complained for about 4 ot 5 years before they put deleting differentials back into their software. Then acronis decided to start offering yearly licenses automatically renewing and added pay per year per GB cloud and anti virus into a backup program rather than fix the backup program they had, then they decided to go pay per year rent only NOT even allowing existing users with permanent licenses to buy more licenses for the software they already had full licenses for. At tis point I jumped ship to macrium reflect just as Acronis did a product rebranding exercise rather than fix the things people where complaining about... Their backup software did not even allow you to select your own drivers from your own windows install so if you had fancy network cards, host bus adapters etc your recovery image had no support so you could not recover. There was no bit locker support so if you had bit locker encrypted drives you could not read them from their recovery medium.. it took an acronis forum member to write scripts to inject drivers and bit locker support to make the recovery medium actually useful to recover with because acronis could not be bothered to do it themselves.. In my opinion without the forum contributed scripts acronis would have been abandoned long before their product lost focus and became pay per year only. In my personal experience acronis lost the plot... just look at the stream of complaints in their support forum... macrium reflect on the other hand allows you to select drivers from your existing windows when you build recovery media, allows deletion of differentials and the recovery medium supports bit locker out of the box and is still buy once own forever.. They also dont seem to bring out a new version every year with lots of useless features. -

just XOR each byte of the data with binary 10101010... The algorithm is extremely fast to both encrypt and decrypt, is one of the few encryption systems that takes the same time to encrypt as decrypt, the encrypted data is no larger than the original data It does not rely on a "random" number generator backdoored by the NSA to be predictable. It is also one of the few encryption algorithms that is exportable without a license and can be used in products sold to countries such as North Korea. Almost all processors implement XOR in hardware providing hardware accelerated encryption the algorithm is simple enough to be implemented on 8 bit and 16 bit architectures providing true cross platform portability and compatibility. To make the encryption key more difficult to guess it is optional to rotate the key by 2 bits to either the left or the right i.e. 10101010 -> 10101010. Implementing the key shift does not break compatibility with systems that don't bit shift the key, this is true even if the data is encrypted on a system that left shifts but is decrypted on a system that right shifts the encryption key. Similarly deciding when to do the shift e.g. after each encrypted byte, after a block of encrypted bytes or after a certain time does not break compatibility with systems that implement a different algorithm for deciding when to shift the encryption key. It is even possible to make multiple copies of the key and encrypt the key with the data and still maintain compatibility with systems that encrypt the data with the key.. it is possible to increase the size of the key in 2 bit increments to any size up to the length of the data being encrypted allowing for keys far larger than supported by AES, DES, etc. Encryption key distribution is often a weak point in a system especially if the key is sent over untrusted networks like the internet. With this algorithm it is totally unnecessary to provide the receiver with a copy of the key, avoiding key distribution entirely. If you forget the encryption key you can recover it by XORing a copy of the unencrypted data and the encrypted version Overall the advantages to this algorithm are considerable.

-

Like most pre-amplifiers the blue hawaii topology is actually an attenuator followed by fixed amplification stages. (in the case of the blue hawaii totalling x1000 times gain). The amplification stages will amplify by a fixed amount regardless and independently of the blue hawaii volume control. The blue hawaii volume control simply reduces the input voltage before it is then amplified by x1000. This means any noise on the inputs will also be multiplied by 1000! if you bypass the volume control so you need a quiet pre amp and sources. One thing to be cautious of is, when you switch off anything connected to the inputs of the blue hawaii if thing being switched off creates a thump or generates a dc offset as it is shutting down the blue hawaii will be multiply it by x1000 and sent it to the headphones... THUMP! SIZZLE! So its highly recommended to have the blue hawaii volume at full attenuation before you switch anything else on or off. You can get a similar situation if you switch off a preamp before switching off the power amp in a loudspeaker setup. Other than this their should be no problems and in fact some forum members have built blue hawaiis and similar without volume controls in them.

-

I think you might be correct, mouser has it as end of life, but on semi does not and none of the other usual suppliers do. Hopefully mouser is wrong. So hopefully it is not EOL..

-

I just sent him a private message on this forum. I told him that I wanted them for a mostly modern T2 build and that I just needed a few - enough to build one amp and a set of spares in case the build went wrong, and was not going to resell them for scalper prices on ebay....I suspect he might be less inclined to supply if the intent was to resell - especially for a profit.

-

I have purchased 2sk216 and 2sj79 from spritzer for a mostly modern t2 build. The prices might not be cheap compared to the price of the transistors when still in manufacture but they are now increasingly rare and the market is flooded with fakes. You are getting genuine parts if you buy from Spritzer - unlike pretty much every seller on ebay which are selling fakes and ebay does not give a care.