jamesmking

High Rollers-

Posts

406 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Everything posted by jamesmking

-

the smd version is at https://www.head-case.org/forums/topic/12733-balanced-to-unbalanced-board/page/2/ intermixed with the balanced to unbalanced board discussion. It looks like it is based on the 2017 through hole and does not have adjustment pots for dc offset. The 2018 through hole version has extra circuitry for controlling the dc offset and adjustments pots. I built the through hole version 2018 and found that with a 10K tkd pot on the input it had some high frequency instability with the volume control almost all the way up. I also got some dc offset with varied as the buffered heated up. The transistors gain seems to be very temperature sensitive and although I matched the pnp transistors and matched the npn transistors I could not get a good match between the npn and pnp - the slope of the curves were too different. I don't know if a smd version of the 2018 was released.

-

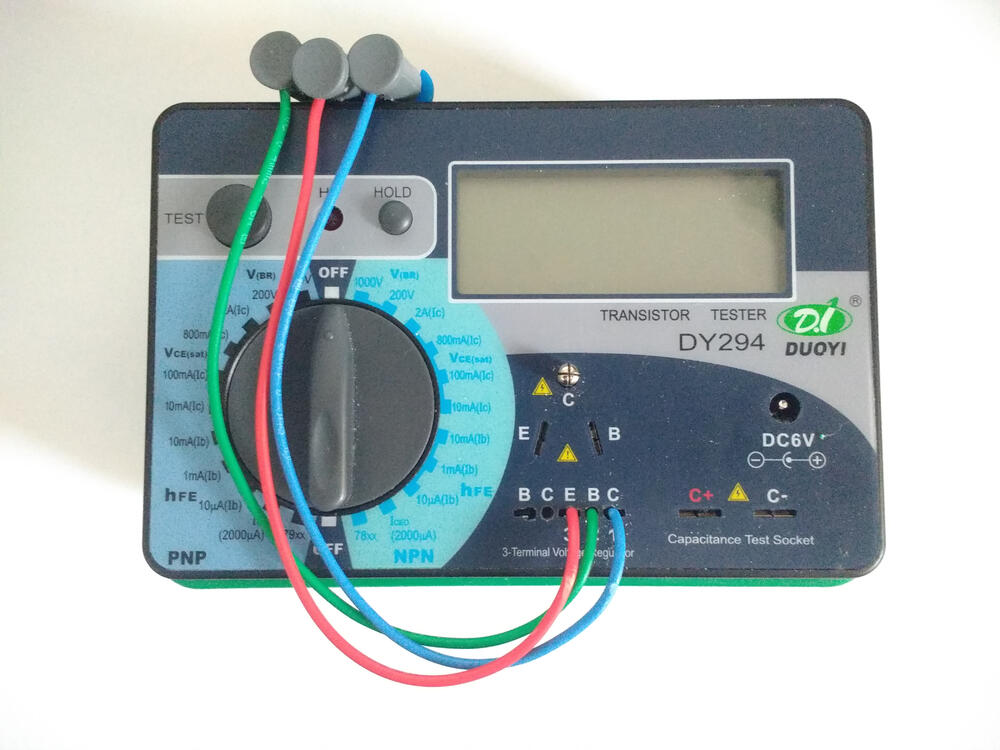

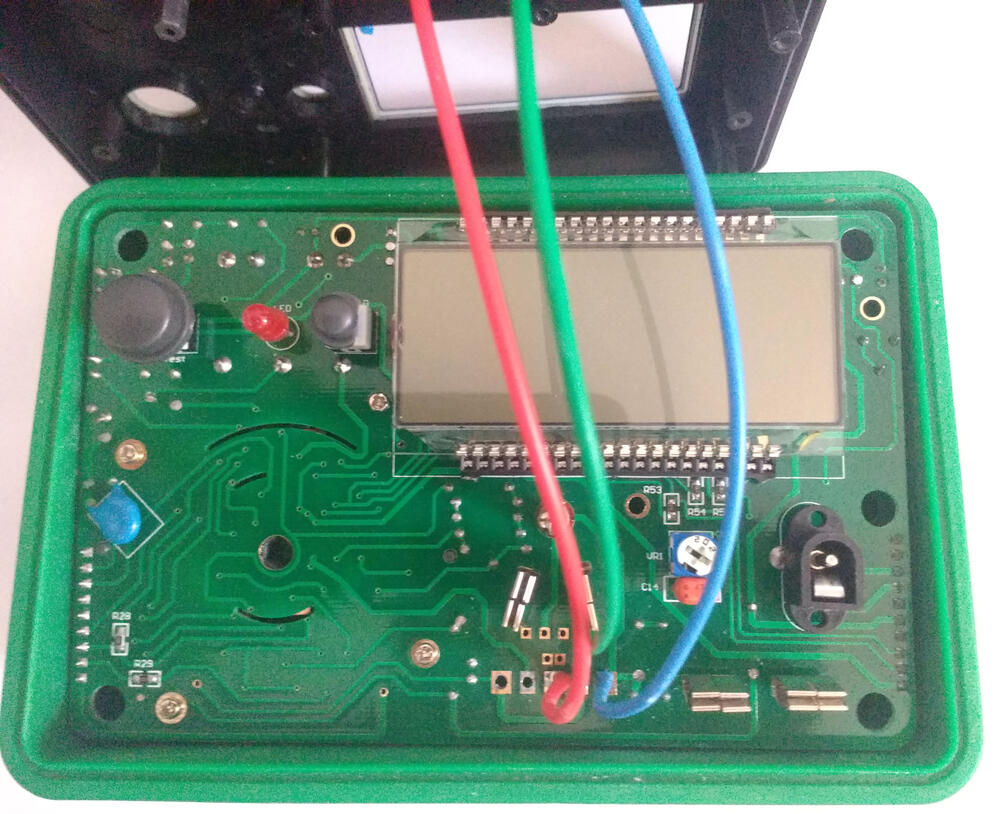

rather than create an adapter I soldered clip leads onto the pcb and ran the leads through the existing holes in the plastic case: The clips also allow me to use adapters for sot23 etc etc. (the same adapters I also use with my peak dca75 transistor tester and identifier)

-

I agree a lot comes down to how much you are going to build and your budget... however sometimes solderwick cant cut it. I once soldered an octal socket on the wrong side of a 2mm 2oz copper board.... solderwick that out 😱 desoldering station to the rescue, board and socket survived. the socket was ptfe round pin with tight pcb holes. 😬

-

good soldering technique and understanding what is going on when you solder: (a little wordy, somewhat dated and slow paced but the latter part of the video has lots of useful info). I heartily agree a good quality temperature adjustable soldering iron is essential and it will make soldering easier, more consistent and you will get better joints. Something along the lines of the hakko fx888d (although the use interface is horrible) that has descent power and is reliable and has repeatable temperatures. also good quality solder and good quality flux I would add a good quality multimeter, one that will not blow up in you hand if say by accident try to measure a 400V psu rail when the meter is in resistance mode... and yes I am speaking from experience here.... I was tired had already lecturer for 9 hours that day. its not cheap but I really like the brymen BM869s. - or one of the lower end models they seem to be very well made and robust. If the multimeter supports temperature probe(s) all the better for verify transistor case temperatures are not excessive etc. joe smith one you tube has done some excellent videos comparing and torturing multimeters for reliability and high voltage tolerance. for proper verification of stability, checking for clipping, etc a signal generator and scope are necessary. For a signal generator the bare minimum would be the analog output of a sound card on a pc and some software to generate sine waves, triangle and square. given the high voltage outputs and rails the scope needs to have switchable x1 and x10 probes (x10 is actually divide by 10 so you can get 400V down to a more manageable 40V). Scopes can be dangerous to use since the ground wire on the probes is actually earth referenced and is clipped to something in the circuit which is not at earth potential you get the possibility of a short to ground.... Some form of desordering to 1. fix mistakes, 2 make repairs. The cheap option is solderwick or a spring loaded desoldering pump. The far more expensive option is a desloldering station. For me using a soldering iron and solder wick has resulted in to many lifted tracks and is too slow and clumsy. something like this works well and is worth its weight in 2sj79s. There are many similar types out there. it is temperature controlled and has a vacuum pump to suck out the solder. For safety a variac is also very useful it allows you to slowly increase the voltage going into the psu so that if there is an issue it would hopefully manifest at lower voltages and hence reduce the collateral damage once you get more serious a transistor tester and identifier can be very useful especially to check for bad components or to post mortem when the "magic smoke comes out". It can also do small signal transistor and led matching. if you are going to do any surface mount soldering there are multiple ways to do it. fine tip soldering iron, hot air station, reflow oven. Magnification is useful - . The cheap ones can be really uncomfortable and can slide off your head easily but if your eyesight is not 20/20 I find them essential for surface mount and for generally inspecting joints etc. now some "luxury" items to make life easier etc The duoyi allows you to test high voltage zeners and also aids in detecting fake old stock transistors by providing non destructive transistor breakdown voltage testing. The instruction manual is crap and the sockets are junk. But with some modifications it works well. another luxury is an LCR meter - this can allow you to match capacitors and inductors and also can measure lower capacitances e.g. a few PF than a multimeter can manage. It can also measure the effective series resistance of caps and other parameters so you can compare caps and identify worn out caps in old equipment. super luxury items because you are addicted to building: distortion analyser super luxury? ultrasonic cleaner. flux residue can result in joints degrading over time and at the voltages some stax amps work at e.g. the T2 the residue can conduct and cause failures. super luxury: sometimes the provided gerbers are the wrong shape, don't fit your style and you wish you could change them. Sprint allows you to import gerbers, modify and re-export. Its relatively cheap. https://www.electronic-software-shop.com/lng/en/electronic-software/sprint-layout-60.html?language=en super luxury: sometimes you want to make your own schematics: https://www.electronic-software-shop.com/lng/en/electronic-software/splan-70.html super luxury: hands free thin probes for smd or when you don't have 3+ hands available. (The same company also sells hands free multimeter probes). disclaimer, all items shown here I own personally and use regularly. However, other builders may have their own favourites and peoples priorities and build styles vary. So these are suggestions and nothing more.

-

goldenreference low voltage power supply

jamesmking replied to kevin gilmore's topic in Do It Yourself

GR78xx and gr79xx are surface mount versions of the golden reference LV without the input or output smoothing capacitors. In general the golden reference LV come in dual (both positive and negative supplies on one pcb) or separate plus and minus pcbs. The gerbers can be found at: https://drive.google.com/drive/folders/0B_iJFfZStuVhSE5nOHBVdTByR1k the latest dual golden reference that I know about is goldenreference6D.zip this is marked on the pcb as version 0.45: the dual output board has provision for 25mm diameter input smoothing cap and optional output on led. https://drive.google.com/file/d/0B6JqIzEX9jZ0LTQ4ZG9HTDE2U0k/view?usp=sharing the individual rail pcbs are goldenreference6minus.zip and goldenreference6plus.zip: https://drive.google.com/file/d/0B6JqIzEX9jZ0ejFrM2lQZnFMa0U/view?usp=sharing https://drive.google.com/file/d/0B6JqIzEX9jZ0R1NpaDNuSzl4NHM/view?usp=sharing there is a goldenreference7plus.zip and minus but the pcb markings for them say 0.43 and do not have an option for a led showing the output is on, however the board allows for a larger diameter input smoothing cap at ~35mm diameter. https://drive.google.com/file/d/0B6JqIzEX9jZ0UFRaQzJSd1UwOTQ/view?usp=sharing and https://drive.google.com/file/d/0B6JqIzEX9jZ0YksyazZ0QXZ5djg/view?usp=sharing -

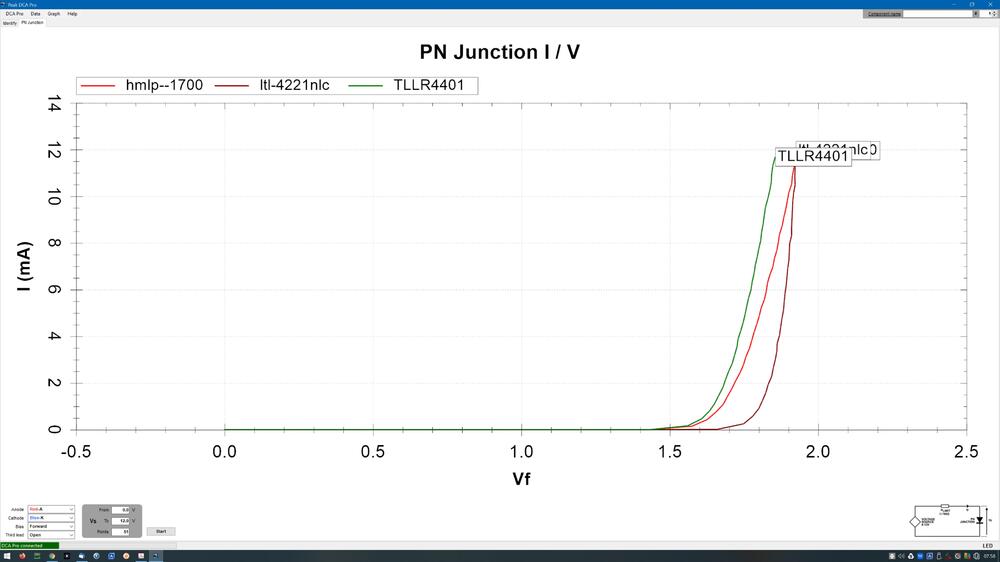

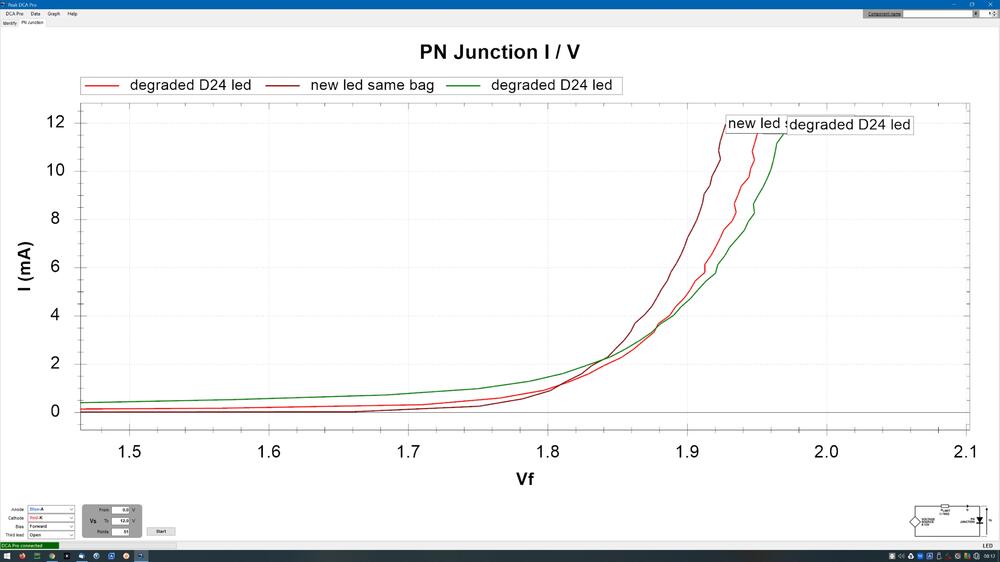

the fresh led has a sharper curve than the used ones, I am zoomed in on the curve, If we look at the full curve the LtL-4221nlc is sharper compared to the HLMP-1700. The TLLR4401 looks promising but is also not quite as sharp. I almost feel like putting 2 pin sockets in the D24 position and trying different les to discover which sound best 🙂 Xicon 273 series. Although discoloured they are not burnt. The drift from new was less 140.5K -> 141.5K so not actually that significant. I did place them on the underside of the pcb. This time I'm placing on the top side and I think that will be enough. Although 0.42W through a 0.5W part is still a little close to the limits for my tastes. I have modified my gerbers to include 4mm airflow holes under each pcb. I think one day I will build a second T2 with some modifications built in.

-

the style of that 6 in the 2sk216 seems a lot different from mine. But maybe they changed font... perhaps its a 7s2sk216 (7 2sk216 is series. in a single package)... 🤪 I just tested a few of mine. Setup on the DY294 : selected NPN gate and source connected to the emitter on the dy294 drain connected to collector on the dy294 and I get around 230V breakdown. spec sheet says 200V.... ----------------------------------------------------------------------- My peak dca75 in identify mode says the following: N-Ch Enhancement mode MOSFET Vgs(on)=0.557V at Id=5.01mA and Ig=0µA Vgs(off)=0.080V at Id=5.3µA gm=25.6mA/V at Id=3.0mA to 5.0mA Rds(on)=6.1Ω at Id=5.0mA and Vgs=8.0V with body diode

-

I think it might well be thermal. About a month ago I replaced the groove tube el34s with modern production branded mullards and the bases of these run far hotter than the groove tubes so that could also have contributed more heat conduction to the leds... I did match all 6 leds in the amp by curve tracing on a peak dca75. The other 4 leds still work well and have very similar voltage drops meanwhile both the D24 leds (which are positioned close to the El34s) degraded. I did not raise any of the leds off the pcb and I think there was excessive heat conduction from the pcb into the underside of the led. This time i'm using leds from the same batch but have raised them off the pcb and time well tell if they degrade. I carefully de-soldered the degraded leds and curve traced them. As expected their characteristics had considerably changed compared to the rest of the leds in the bag. The D24 led on the left channel which is closest to the EL34 had the most change from new and the lowest voltage drop in circuit 1.4V in circuit, the righthand channel D24 is a little further from the EL34 and in circuit had 1.5V drop and is a little closer to a new led which has a drop of about 1.7V in circuit. To put the change into context I measured multiple leds from the bag and the curves almost superimposed over each other. So the drift in the D24 leds is significant.

-

testing breakdown voltages would be a good idea. Fingers crossed you have a real ones. Here is some high resolution photos of a known good one from a reliable source- and its brothers are working my T2... Markings are printed not etched and are a greyish cream colour not white. (photo has been colour balanced). Ends of legs are fairly sharp. close up of the circular area in the middle. Lighting adjusted to make the text in the dimple more readable at the expense of the printed markings. Text in the dimple is raised. The starting angle relative to the top of the transistor for the word MALAYISA and the associated number and letters in the dimple varies between the 216s I have.

-

happy birthday Kevin, thank you for bringing so many diy projects to life and for you advice and troubleshooting help.

-

Longish term modern DIY T2 reliability. I estimate its been used around 8+ hours (and more often than not 12 hours) a day almost every day since I built it. yesterday I took it apart for cleaning. I noticed all four 140K resistor strings connected to the voltage reference in the virtual batteries where somewhat discoloured.... hmmm... on further testing I found the D24 led on both channels did not light up at all not even dimly. :-(. but the amp seemed to work and sounded good. (on the left is a brand new resistor from the same pack as the 140Ks I removed from the virtual batteries.) I checked also psu voltages - good. I measured the voltage across the D24 led- about 1.4V. When the amp was originally built these leds definitely glowed as strongly as the others. All the leds where tested before soldering in and were from the same bag I even hand matched them just for overkill. The D24 leds are part of the circuit that provides base voltage and current to transistors that provide feed into the virtual batteries. I checked the virtual batteries - all were 741V on startup and the adjustment pots could adjust the output. So the batteries look good despite the slightly cooked resistors. I removed the voltage references and tested them in a glden reference LV - all good. The discoloured resistors can be explained by the fact they have about 0.423W flowing through them excluding base current draw from the 2 transistors and are on the underside of the board with little airflow - maybe1W would be better or some airflow holes in the pcb, or mount them to the topside of the pcb. So I decided to de-solder the 140K resistors for measuring and the 140K resistors have drifted slightly but all measure within 141.5K. So a little cooked but probably not the case of the problem. But why are the leds not lighting.... Looking at the circuit diagram the D24 leds should get about 0.5mA current excluding any draw from the bases of the transistors. (560V / (560K *2 resistor string to ground). I used the exact SAME leds for the other positions and it also looks like those leds get about 0.5mA excluding base transistor draw and they glow nice and bright. I de-soldered the leds and tested the D24 resistor string to ground. They spot on resistance and have not been damaged or drifted and so should provide 0.5mA current draw through the led. However the desoldered D24 leds would not glow at all with diode check on my brymen BM869s multimeter but do pass current and are not open or shorted. I tried my keithley 2015 in diode check mode (it has adjustable test current) and got absolutely no glow at 10 or 100micro amp but did get strong glow at 1mA - same situation on both D24 leds. I tested my remaining leds from the same bag and they glow on the brymen admittedly fairly dimly, and glow on the keithley at 100 micro amp again dimly but visibly. (I did test all of them on the brymen before soldering into the amp). So the leds in D24 have degraded over time . I used the same leds in the other places in the amp and they are all fine. This would explain why the batteries are working but the leds are off.... So the plan is to do some more testing on the leds and replace them with another model. But what's causing the leds to degrade in brightness on the -560V rail when the others have not? any ideas? regards and and I apologise for the long winded post James Update: I replaced the D24 leds... they now light brightly with a voltage drop across them of about 1.7V. I replaced the resistor strings with the same resistors but now placed on the top of the pcb, raised from the pcb by about 1cm. After a ten minutes with no lid on the amp the resistors reach 65C on the top and 71C on the sides. So its easy to see how on the underside of the pcb with the lid on they could reach temperatures which could cause discolouration.

-

water cooled data centre means you can overclock the cpu(s) more....

-

fantastic. I was about to lose all hope. thank you to everyone involved in getting head-case back online

-

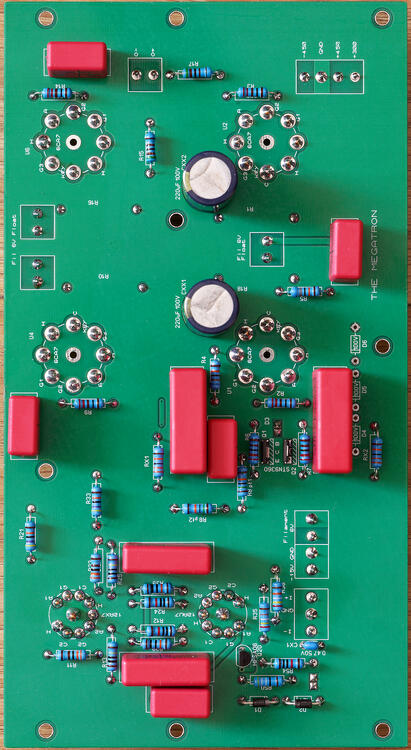

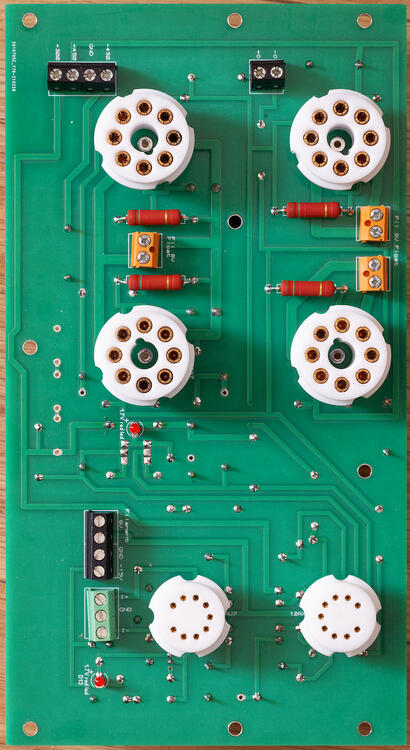

Megatron Electrostatic Headphone Amplifier

jamesmking replied to kevin gilmore's topic in Do It Yourself

My megaslow build. Thank you JoaMat for supplying the 3 mosfets I needed for the golden reference psu. The megatron is workingish. This build was a little perplexing. I used groove tube 12ax7, electroharmonix 12au7 (gold pin) and groove tube el34s. I implemented the 12ax7 increased current modification form the outset. I found that I could only get about 220Vrms output before clipping. The clipping was not symmetrical and it was the bottom of the wave on the +O that was clipping only. I started to probe with a scope and found that the voltage drop at the 330K anode resistors on the 12ax7 was only about 19V on the +O side and about 35V on the -O side. Everything else looked fine. I scoped the output of the 12au7 when the amp was fine - no clipping when the output of the amp clipped. I checked all the psu voltages - no problems. It was the output of the 12ax7 was asymmetrically clipping. I took the valves out and measured them and the 12ax7 was only managing about 0.5mA output on one plate and about 0.8mA on the other. The avo manual said I should be expecting about 1.2mA. I was not sure if the amp had damaged the valve or if the valve was weak. So I checked the amp and removed the extra current modification and tried with a stronger 12ax7. Now both the +O and -O clip at approximately the same point but the clipping is still asymmetrical. I'm getting about 35V to 40V across the 330K anode resistors on the 12ax7. The bottom of both outputs clips before the top, and I am getting about 440Vrms output before clipping. I got in an email conversation with watford valves and the proprietor said that almost all new production 12ax7s are only capable of about 0.8mA and that only new old stock could do 1.2mA. So the high current mod might not be an option if you are running new production 12ax7s. I did some frequency response measurements and found the -3db point was only at about 23-24Khz... which seems rather low. Could someone tell me what output voltage rms they are getting before clipping and the -3db point for verification. thanks in advance James -

it seems like at the moment the only thing in stock is out of stock notices.... 😞 check the height of the 1000uF cap... at 105mm tall its a beast which will not fit into a 2u case. (around 65mm depending upon the height of the standoffs for the pcb is about as tall as you can go for a 2U (80mm tall case)... are you going 120mm tall 3U case? the issues with very large capacitance input caps is that they will create a very large inrush current on switch on so you may need a larger value fuse than you would otherwise. Also the larger the cap the more diode switching noise it will cause because the caps will pull more current for shorter periods of time from the diode bridge rectifier. For the output cap some psu can become unstable if the output cap has a too high (or too low) capacitance. You may want to send a private message to kevin gilmore - the designer of the golden reference psu to get his input. Personally I use 470uF most of the time on the golden reference because I could not find any 680uF caps that would fit into the 2U cases I use.

-

if you are referring to the high voltage lines on a diy t2 - those psus use two 450V caps in series for double the voltage rating of one cap at the cost of halving the capacitance (except for rails bellow 300VDC output). The golden reference does not use series capacitors like this. the golden reference uses a single input and output cap per rail. So the each cap has to withstand the full voltage by itself. if the output is 400V then 450V is ok for the output cap giving you 10% or so margin. the input cap will need to have a higher rating than this because all regulated power supplies require more input voltage than they provide output voltage so they can maintain regulation. I think, if I remember correctly, the golden reference is about 330VAC input for 400VDC output. 330VAC once rectified through the diode bridge will give 330* squareroot(2) ~ 466Vpeak. Plus main voltage can vary, plus transformers can vary so to be safe you would want at least a 500V input cap. You may be able to get away with a lower input VAC if the golden reference can maintain regulation and your line voltage does not sag. Also consider that the higher the current draw the lower the output of a transformer and visa versa. So if you over spec your transformers current capacity the output voltages can be higher than you expect...

-

the quick 861dw comes highly recommended its also useful for drying out pcbs after ultrasonic cleaning, removing surface mount components, heat shrink etc.

-

I did some experimentation and found that low airflow and fairly high air temp worked best for me. I have a quick 861dw hot air station. I set the airflow to 5 out of 120 and set to 360C (the temperature will depend on your solder paste melting point). I hold the hot air nozzle with one hand and with the other I use tweezers to keep the smd part in place. If you do not hold the part in place almost any airflow will send components into low earth orbit. The tweezers I use are curved on the end which makes it easier to place components, keep your hands away from the heat and easier to see what's going on.

-

and now for something completely different part 3

jamesmking replied to kevin gilmore's topic in Do It Yourself

opa134pa is exactly what i am using and is fine the LT1021DCN8-10#PBF is about half the price of the version of the reference your are proposing. The output accuracy is a function of the accuracy of the LT AND the divider network (which sets the output voltage) by taking the output and dividing it down to a nominal 10V. This is fed to the opamp which acts as a comparator between this and the LT. Unless you are going to use 0.1% or better tolerance hand picked resistors for the divider network there is not much point in spending $$$ on a very accurate version of the reference when the divider resistors are 1% and will drown out any extra accuracy a more expensive version of the LT will provide.... If you want high accuracy and don't want to spend $$$ you can always hand measure and match the resistors to get a more accurate output voltage (if you need that level of accuracy). -

Megatron Electrostatic Headphone Amplifier

jamesmking replied to kevin gilmore's topic in Do It Yourself

well my amp boards for the megaslow build finally arrived today. I have decided to use a golden reference HV psu for the +-450V and a second golden reference hv for the +300V. The psus are finished other than I don't have and cant source the pass mosfets.... *sigh* One question. since I will be using a 300V psu do I need to populate the 3*100V series zener string connected from the 300V line down to ground? I assume the zener string is there to stop the 300V line rising above 300V with respect to ground if the 300V line is derived from the +450V line via a dropper resistor.. or is there another reason why the string is there? -

The pcb files are in zips with the contents in a format called gerber which can be uploaded to a pcb manufacturer like jlcpcb. The gebers contain all the necessary information for the creating the copper tracks, drilling of holes, silkscreen printing etc. Often there are minimum order sizes of around 5 of each type of board so often people have spares... There are no step by step instructions. There is an assumption that you can read a schematic, are prepared to read through some very lengthy forum threads and do basic drilling for mounting boards to heatsinks etc. the information is a bit spread-out. In general you need: BOM - bill of materials to get the right value and size components. Downloads from the appropriate forum thread for your build (and possibly two threads - the second thread being for the power supply) schematics - for troubleshooting etc in the forum threads and or download from https://drive.google.com/drive/folders/0B7egryukiT7_TFlEQlBRejdVdDQ the gerber files for getting the pcbs made in the forum threads or download from https://drive.google.com/drive/folders/0B_iJFfZStuVhSE5nOHBVdTByR1k the specifications for the transformers. in the forum threads. advice. in the forum threads and ask in the threads. in general the markings on the pcbs takes precedence over the schematic or bill of materials (unless the pcb has a silkscreen error). Some amps have more information than others - the threads grow organically over time depending upon popularity, etc. In general support is available for everything on a voluntary basis. You post questions on the appropriate thread hope for someone to answer. There are some very knowledgeable and helpful people active in the forum for example Kevin Gilmore, Kerry, JoaMat. Often the people who created the design will answer questions in the forum posts or people who have actually built one or even modified one. Unless you have lots of money/luck/ or existing stocks of obsolete components obtained from known good sources, I would stay away from any design which requires no longer manufactured transistors. There are many fakes floating around which can and will fail catastrophically on first switch on and non fakes are rare and there are few trusted sources willing to sell to non friends. I would advise reading the forum threads from start to finish and making notes, that way you can see the different versions/modifications emerge, see issues with certain components for example in the DIY T2 thread the voltages are high enough that some makes of resistor sparked and the insulation broke down.... Look at what people did that worked or did not work and learn from their experience. Finally if you can, give as well as receive. Post what works for you, post pictures, post updated bills of materials etc.

-

I also have the peak dca75 and several adapters. It can't test at high voltages or currents but its insanely useful for identifying transistor pinoutsand the type of transistor. I have used it several times to identify bad/failed transistors making troubleshooting much easier. The windows software also provides curve tracing which is useful for matching small signal transistors and leds.

-

Digital-First Retail Limited owns Maplin. the company did not exist prior to 29 June 2018... and has changed the location of its registered office no less than 4 times since then... The original director of the company resigned 6 oct 2020. The accounts only show 2 employees ... so im guessing its a shell company. The accounts is interesting section 476 means no requirement for external audit of accounts, section 477 companies act 2006 exemption from audit and exemption from publishing a full statement.... so the entire financial statement is simply one line current assets, one line creditors amount due and one line net assets. current director is director of 1 other company and previous director of another - all from the same address.

-

quick heads up KSA1220AYS transistors are now END OF LIFE https://www.mouser.co.uk/ProductDetail/ON-Semiconductor-Fairchild/KSA1220AYS/?qs=ljbEvF4DwOOJTVoo5AYsWQ%3D%3D 😞 mouser is currently out of stock radio spares has stock farnell is out digikey is out