-

Posts

40 -

Joined

-

Days Won

2

Content Type

Profiles

Forums

Events

Everything posted by Aumkar Chandan

-

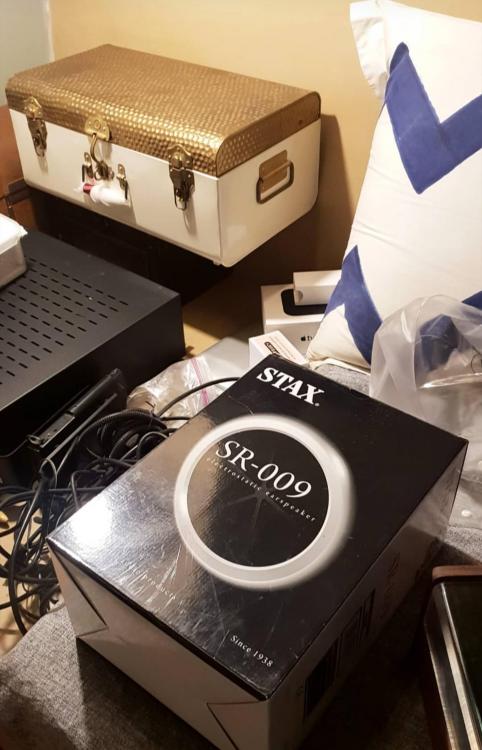

I thought I'd share this here. Yesterday, I flew down to meet some of the most prolific Electrostatic collectors in Bangalore, India. This was their first time seeing or listening to the RR1 Conquest - A lot of the people there were STAX owners of course, many owning 009s, 007s etc as well as some very sophisticated Amplification was present there as well. I also brought along the XP1, which stands for "Experimental Prototype 1". The XP1 was our original test mule that was created to be subjected to the worse possible conditions and also served as our stress mule, having over >3000 hours of service. It was on our dummy head running various impulses for 4 months, 24 hours, all day every day. It still lives but I had to open and clean the drivers once as there is intentional lack of dust protection on it. The XP1 is named after the McLaren F1 XP1, which I regard as one of the greatest examples of man and machine harmony. The XP1 is a special chassis that I intend to keep for my personal collection. Here are some impressions from the folks at the meet (I have taken a direct screenshot from the TIAF group) - I'm glad they liked it but I will say this - I don't like hype. It's the worst thing in the world. These guys are quite experienced and have been in the game longer than me but I still say, take it with a grain of salt. I might be the only Manufacturer in Headphone history to say that but, that's how I like doing business. I don't like hype, that's why I will be travelling around the world to show the Headphone this year. Hopefully, people get to hear it for themselves! Also, this was my first time listening to RR1 on the KGSSHV Carbon and oh boy! I have two "normal" KGSSHVs on order from Spritzer as my primary Amplification for international shows, I think I will need to get the Carbon too for my home setup. That thing is pure lunacy.

-

Yup. Walls, wheels and earpads. They are promethean.

-

Hello Sir, Yes. you could block the port on a dry day. The port is easy to access. Here's a picture : TPU : Thermoplastic Polyurethane, an industry common thermoplastic used for gasket/bushing applications. Our Dust Covers are glued to it and are fully sealed on top of being mechanically torqued by the housing.

-

I agree, that is what any logical person/company should do . That's why STAX has been doing it for years and what many industry people have told me as well, but..there is dust protection. The only difference is the form. STAX uses crumpled PET as well as almost everybody else. I use a Polyester based fabric which is TPU gasketed to the entire Driver from both sides. If we talk numbers, dust particle size averages from 5-500µm compared to a diameter of 12-15µm fiber diameter for Polyester. That's just the fiber diameter, not the inter-weave distance. Now, even if the Headphone was positioned with gravity, the chances of dust getting through the fabric is slim. Not to mention the inherent tensile strength advantage for the fabric over a crumpled PET which is known for tearing and infamous for a certain headphone that was opened up on this very forum here which had holes in the dust cover from the factory. Another thing, I didn't enjoy the Manufacturing process of crumpling dust-covers and don't find the Acoustic trade-off worth it. Some say it doesn't make an Acoustic difference, it did for my system hence I chose not to use it. You could but I don't recommend it as the RR1 front area is quite hermetically sealed and will inevitably lead to sweating.

-

Hi Arnaud, Yes, the design does have some impact but is negligible compared to spatial tolerances in the FR due to the inherent, narrow dispersion patterns by Electrostatic transmission. The RR1 initially wasn't an Electrostatic, I was developing a new transmission type which was an Electrodynamic derivative with a key component eliminated to reduce mass but because of budget/technical constraints, I had to stop the R&D. The system was designed to be angled. Hence, we took the same chassis and engineered an Electrostatic system around it. As you might know, Electrostatic drivers are useless at an angle. Yes, my design is indeed ported but not for Acoustic reasons. The port is a pressure/humidity relief port. My drivers don't use a traditional dust cover system like others and hence have a different reaction to turbulent patterns which make the diaphragms sensitive to collision to the Stator only if there's a sudden pressure change when the system is operating at an high SPL or if the system isn't coupled to the head while it's is baised. The port reduced the effect to a certain level but is still a characteristic of my system, no big deal to be honest but is a place where I think I can definitely improve upon. The port also helped to reduce moisture build up which was a very critical issue I was facing in the R&D - voltage breakdown. I'm in Mumbai so this triggered it more than it would elsewhere. We also experimented with Hydrophobic coatings but had no success. Without the port, the bass extension was among the flattest I've measured on an Electrostatic but, to address the stability issues, I had to port for all the above reasons. Hope this answers your questions, don't worry about me not sharing something. I could care less about keeping trade secrets. No progress can be made without sharing your findings. I've read your posts over the years and I really appreciate your service to the community. Same can be said about Wachara, Birgir etc.....

-

This is what a "Bespoke" RR1 could look like, this is just a pretty random spec I came up with. Anything is possible, really. This is the regular production spec (full stealth) -

-

Yes, there will be a "Bespoke" program where the RR1's can be customized to whatever you desire. I'm still working on my website where all the details will be mentioned with lead times for production, costs & other customization possibilities (technical as well as aesthetic)

-

HI Jose, Majority of sales will be through my website (direct). Distribution will be hard to achieve but of course, if I can strike an acceptable deal with distributors then we will definitely build a network. Wachara, my film isn't different from regular PET. We just make it ourselves which I find a little cool! Kinda like how Grand Seiko grows their own Quartz crystals. The RR 1 Conquest is almost 98% made in-house. The only part we don't make ourselves is the Earpad, I spent a year trying to make one that looked production quality but did not succeed. I finally had to go to China for it. Our Earpads are made at the same factory where many big name Manufacturers get theirs made as well. RR 1 Earpads are bespoke, not off the shelf.

-

Wachara, Total area is 80 x 70mm, well...79.90 x 69.90mm to be exact. Diaphragm is a in-house sub-2 Micron PET. We tried 600Nm but due to the poor Young's Modulus, it was almost impossible to tension and/or get any decent bass. To successfully use a Nanometer film, I personally think the Matrix requires better filler geometry to improve the Young's Modulus but, with current Polymer technology it is difficult to produce such filler based thin-films at such thicknesses. Diaphragms are manufactured by our other family owned Polymer company.

-

We will be exhibiting at a certain Headphone show in SoCal this June. I think by then I will start taking orders. I didn't do any pre-orders because I don't like holding my customer's money like a lot of other companies. I will only take orders when I have enough inventory to sustain a ship within a day or 48 hours policy. Currently, production is my main issue as all our Stators are Aluminium and require strict dimension accuracy while drilling. Aluminium unlike FR4 can be easily bent and cause several non-linearity issues. There are better ways to machine a Stator other than on a CNC but it understandably increases the production cost and complexity. Our D/S gap is 0.45mm and our spacers have a maximum tolerance of 0.005mm measured across 250-200 points which is as good or even better than STAX. STAX uses brass to combat machining challenges, we use Aluminium with more methodical operations. I am trying my best to increase my production output but there's only so much I can do without comprising QC. If I was here to make a quick buck, I would take taken pre-orders already. Regards, Aumkar

-

Hi Jpleg, I don't think that should be a concern. I don't see myself jacking up the price. Let me give you a quick background about me and my Company. My company is "Kaldas Research"- as the name suggests, we are a Research company. Our main Business is contract R&D and Manufacturing. "Kaldas" is named after my Grandfather Mr. Gokaldas Chandan who was a big inspiration for me as he started with absolutely nothing. Making my own Headphone was a very old dream. I started as an enthusiast with my HD650 around 8 years ago, what rekindled my dream was when I visited Beyerdynamic in Heilbronn back in 2015. The factory and family owned spirit of Beyerdynamic was a big moment for me to consider making my own Headphone. I have been lucky enough to visit G.R.A.S. in Denmark as well as Klippel GmbH, all of them had an impact on me in one way or another. As to your concern, why am I selling at $500? Is the Headphone cheaply made? Does it sound like Garbage? For me, it's simple. I am personally sick and tired of the over-inflation in prices of recent Headphones. Most people are trying to get into the Headphone industry to make money. I am not. I think there are better ways to make money than to get into an overly crowded industry. At the end of the day, I'm just a kid with a passion. The skepticism people have is beyond my control. Regards,Aumkar

-

Hi, I didn't have a reference per se. My main goal was to improve on the Low-Frequency extension compared to most STAX out there and we achieved that. Here are the graphs vs the 009. I wouldn't get into my subjective opinions but I've had two people, one 007 MK1 and MKII owner come and place an order on the spot and another 009 owner who also couldn't tell apart the 009 from the RR1 apart from the LF response being more extended on the RR1. Anyway, here is the link with the Measurements (I have an upload limit here) - https://www.dropbox.com/sh/3rev8hq54sd3feu/AACb7Zs1DFcKZFYhs3co7Ecta?dl=0

-

I agree but the system is fairly safe due to the orientation of the male and female. There's no real way to get shocked even if a certain Aftermarket cable builder screws up Bias with + or -. Let's say they manage the impossible and intentionally try to get shocked. Due to the inherent lack of current and thanks to our reflex action, you might get a cute shock which will only affect someone emotionally for their poor skill of Electronics handling. Thank you for your kind words. I am trying my best to get a unit out to Spritzer as soon as I can for the Stax community. I understand that there's a lot of crap coming out nowadays and it's hard to build trust. I am an enthusiast as well. My personal collection includes an original SR-1, Sigmas and many other vintages.

-

Hi, I’m Aumkar. I’m the guy behind the RR 1. Yes, I will be sending Birgir a unit once our first batch is ready! Haha, yeah. We used it just for the shoot. I didn’t have a KGSSHV at the time. I will be ordering a few soon from Spritzer for our shows (CanJam)

.thumb.jpg.dc88573ff8e6d7c35cefb28a08b13809.jpg)

.thumb.jpg.1333e43f017a51f9f9ba00575cfd690c.jpg)