-

Posts

6,665 -

Joined

-

Last visited

-

Days Won

36

justin last won the day on June 24 2023

justin had the most liked content!

About justin

- Birthday 01/01/1872

Profile Information

-

Gender

Not Telling

Contact Methods

-

Website URL

http://www.headamp.com

Converted

-

Occupation

www.headamp.com

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

justin's Achievements

Super Secret Ultra Gold Member (6/6)

2.3k

Reputation

-

and now for something completely different part 3

justin replied to kevin gilmore's topic in Do It Yourself

600 or 680 can be used. 680 will be slightly higher front end gain 300 is correct 4.2k is just higher gain than 1.9k I don't remember what the 50k and 25k are -- SS feedback resistors? if so also just higher vs lower gain If only using SS, it's possible you can eliminate the 4.2k, as long as there is still another resistor in parallel with it. what you would do is measure the gain with and without the SS feedback resistors, and choose values so you have ~6dB less gain with the SS feedback resistors installed -

and now for something completely different part 3

justin replied to kevin gilmore's topic in Do It Yourself

you may be hearing residual DC offset from the amp boards at the time the relay engages, as it can take a short time for the servo to null this voltage completely - possibly longer than the delay on your power on relay. things you can try: - use ground as the input signals to the protection board, do you still get turn on noise? - measure the DC offset at the time the relay engages - significantly increase the delay of the relay - measure the min. +/- DC voltages that cause the protection circuit to engage, for each channel - lower the threshold of protection -

and now for something completely different part 3

justin replied to kevin gilmore's topic in Do It Yourself

I cant even tell if this is a stupid question but where are your heatsinks? if you try to power it even for a short time without heatsinks the bias is going to be very unstable 3.6V sounds right to me, 5V would probably result in about 700mA bias -

Frank Ricard still did a better routine

-

The output ripple voltage of a DC/DC converter is often specified at a 20 MHz frequency to provide a more comprehensive view of the high-frequency noise performance. Here's why: 1. **Switching Noise and Harmonics**: While the switching frequency of the converter might be relatively low (e.g., hundreds of kHz), the switching process generates high-frequency harmonics. These harmonics can extend well into the MHz range, and measuring at 20 MHz helps capture the impact of these high-frequency components. 2. **Measurement Standardization**: Specifying the ripple at 20 MHz has become a common industry practice. It provides a consistent benchmark for comparing the performance of different converters. It also ensures that any high-frequency noise generated by the converter is accounted for. 3. **Real-World Performance**: In real-world applications, the DC/DC converter might interact with other components that are sensitive to high-frequency noise. Measuring ripple at 20 MHz helps ensure the converter will perform well in a wide range of conditions and with various loads. 4. **Electromagnetic Interference (EMI)**: High-frequency noise can contribute to EMI problems. By specifying the ripple voltage at a higher frequency, manufacturers provide a clearer picture of potential EMI issues, which is crucial for compliance with regulatory standards. Overall, the 20 MHz specification helps designers understand the converter's behavior across a broader spectrum of frequencies, ensuring more reliable and noise-resistant designs.

-

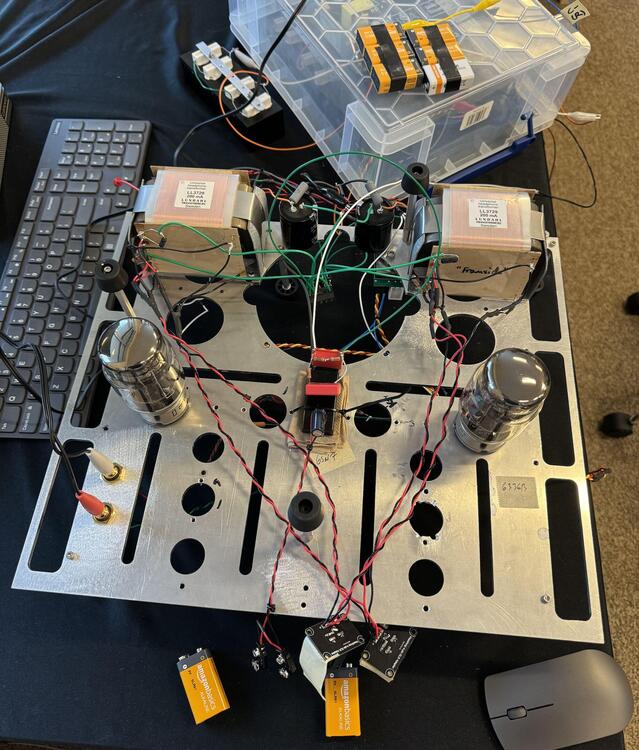

Universal output HP amp with custom Lundahl transformers

justin replied to justin's topic in Do It Yourself

This is all that was provided: I think I would prefer to use our 2.5kg (5lb.) > transformers, as the high voltage secondary needs to have a lot of insulation > to keep capacitances down. > > Spec: > Transformer for SE amplifier, size as LL1620 etc. > > Primary 1.2k impedance, 280V anode voltage, > standing DC current 200 - 300mA (you will need to specify) > Input signal power around 10W > > Secondary 1 (electrostatic speaker) 1600V P-P > (turns ratio 1 : 6). > Does this output need a centertap for offset > voltage or for ground reference? > > Secondary 2 (low sensity headphones) , 15W > into 50 ohms -> approx. 27V rms (turns ratio 3:1 for 1.2k : 50) > > Secondary 3 (6 ohms loudspeaker and sensitive > headphones), 15W into 6 ohms -> approx. 10V rms (turns ratio 14:1 for > 1.2k:6) 3729_SE_connections.pdf -

I met Per Lundahl at Capital Audio Fest last year, and in trying to figure out what I could use I'd have for Lundahl transformers I asked about winding something that can drive e-stats, planars, low impedance, speakers from separate taps. I had also just bought a bunch of 6336B dual triodes, so thought that might work. The transformers came and many months went by but finally rigged something up. Basically right now it's just 6336B with both triodes in parallel, running about 200mA with a B+ of 260V. There's an e-stat output that steps up, and also 50 ohm and 6 ohm outputs. The grid voltage is set by a bunch of 9V in series. The black box in the middle on top of the Wendy's napkin is a little 4W 12V to 600V DC/DC converter for the e-stat HP bias. I'm actually driving it from the headphone jack of a Ray Samuels Raptor right now 🤣 Have sound coming out but no chance yet to do much further testing

-

here is actual footage from Bing

-

tbh I wrote the post BEFORE I noticed subliminal?

-

Are those Monster cables?

-

thank you for your service

-

and now for something completely different part 3

justin replied to kevin gilmore's topic in Do It Yourself

have to look, probably either a OPA2134 or 2132 But I also tried it without the servo and using a pot instead -

I was thinking maybe Roonba or the poon as a Neil Young/Schitt homage

-

I've thought about making a pocketable, portable amp for Roon, does anyone have any ideas for a name?