-

Posts

13,692 -

Joined

-

Last visited

-

Days Won

38

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

Maybe after Serbia joins the EU? http://www.tubes.rs/ The gentlemen that runs that website might have a good lead for you though.

-

Congrats!

-

-

and now for something completely different part 3

luvdunhill replied to kevin gilmore's topic in Do It Yourself

I also have run those voltages through Switchcraft EN3 series which I like a lot. -

Cool. Is that the natural/ clear tint Penofin?

-

This is my first time to use Ipe. It seems that depending on how it’s cut (which seems obvious now, but anyways) there are sections that end up with this sort of mottled grain. This is normal, right? This isn’t end-grain but it’s 90 degrees to the typical smooth lines you see.. I should have better planned for this feature of the wood.. Here is what I am referring to:

-

and now for something completely different part 3

luvdunhill replied to kevin gilmore's topic in Do It Yourself

Where the wires go into the toroid is probably the place to tweak a bit. Rotate them both towards the shaft if possible. The only other issue might be getting the wires safely to the 4PDT switch. -

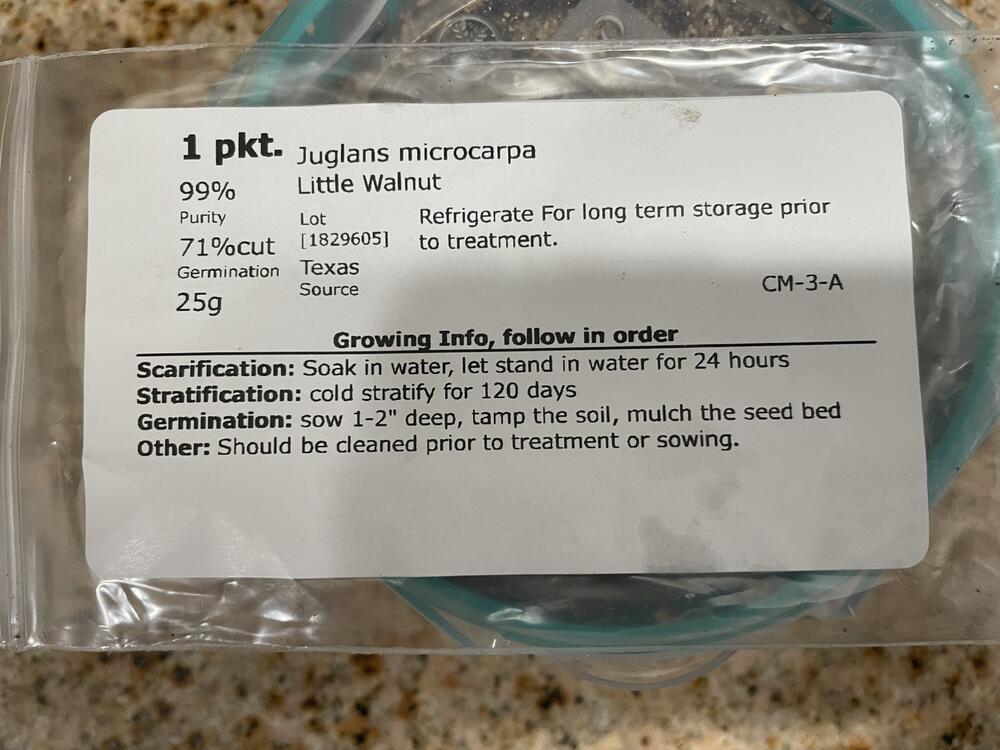

Put some walnuts (Texas Walnut aka juglans microcarpa) into simulated winter … aka in my refrigerator. i think it’s pretty cool that walnut trees give off a poison that prevents other plants from growing nearby and competing with it ☠️

-

If a cnc is a ping pong table, that thing looks more like pocket pool.

-

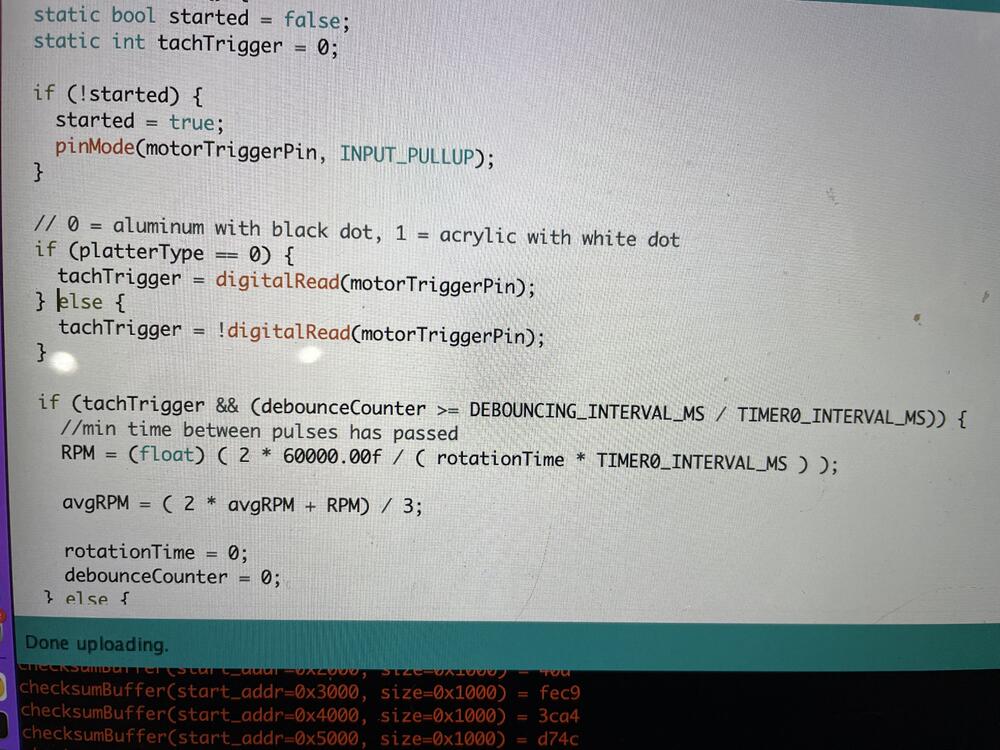

The avgRPM assignment does a bit of smoothing. There are not a lot of mechanical losses, the belt has reasonable friction on the pulley and platter, so it can alter the platter speed with reasonable accuracy without it acting like a flywheel. I don’t know how much is audible but I can say that +/- 0.03 rpm isn’t audible and it makes adjustments less than this. Gor reference, the added friction of lowering the needle into the groove slows rotation about this amount.

-

Do you mean does the motor alter its speed at each rotation?

-

Yup - I guess in this case the difference was black and white.

-

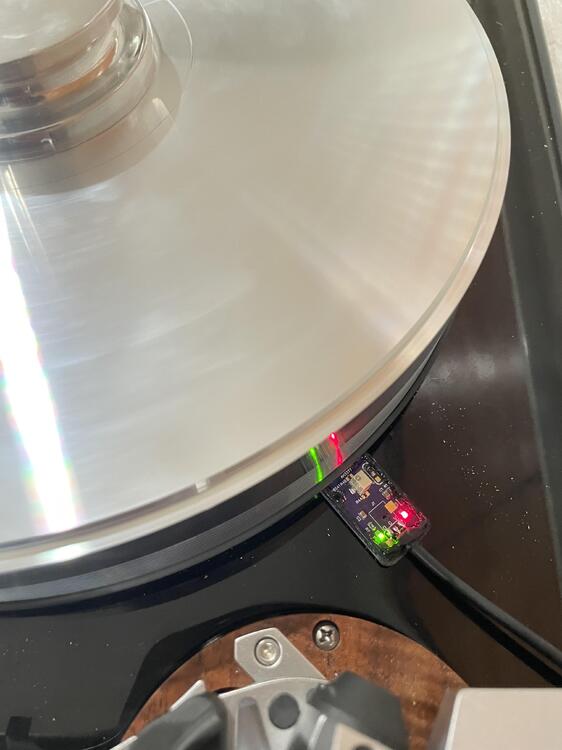

My little box works by counting the number of times it sees something pass as the platter spins. You need to check fast enough so you don’t miss the thing as it passes by. The faster you can check you can increase the accuracy of your measurement. Originally I used a magnet and this worked well but seemed a bit less than ideal near a sensitive phono pickup. So I changed to using light. In order to make the sensor work with other types of light present (such as the light that comes out of a light bulb) I used certain frequency of infrared light. This light is emitted by my box and then when that light is reflected back from the object it notes that the object has passed and it computes the speed. With an acrylic platter with a record on top when the box asks if it has seen the reflected light, it says no until the white dot comes by, which reflects all frequencies of light and registers a “yes” with the system. But when an aluminum platter is used it always reflects the light. So I needed something that didn’t reflect the light I was using, which ends up being a black dot which absorbs light. One made the “physical” change in how the device operated I made a simple change in the code that basically looked for when the reflected light wasn’t present - which was the exact opposite to how it used to work with the white dot.

-

So, a bit of a stretch for this thread and I am doubting anyone will see the humor in this. But as y’all know o have been working in a tachometer feedback loop for my platter. With the lid off it looks like this: Previously I had an acrylic platter with a white dot that triggered the IR sensor each time it went around and used that to calculate the platter speed. Now I have an aluminum platter. To make it all work I had to add a black dot and update the code as follows. .. anyways I found this humorous.

-

-

-

Send all the extras over here for proper disposal

-

So I received the bushing set a day early and think I got it all setup. I guess the dust collection has to come off when using the bushing insert?

-

So working to get my sacd player back in rotation. That means I need to stack two components on top of each other. my rack has one open location, then two shelves behind a door. I have: Pass XP15, Esoteric K-05x, MiniDSP SHD, Berning MicroZOTL (old style) I was thinking of the digital spinner on the bottom, as it needs the rear cutouts for inflexible cables. I like the amp visible on top. That then means stacking the miniDSP on the photo stage or under the amp and not sure which one is better. It’s a tight fit either way. As an aside I will run the spinner single ended as I need the extra balanced voltage swing for my low output carts. I haven’t done this yet so that will be a bit of a change. I guess I need to find a cable long enough - been a while since I bought a RCA cable Any suggestions or thoughts?

-

I found a 6” black and decker polisher for $30 on sale that works really well.

-

Ok, I think I figured it out. I want a 2.5” finished circle, using a 1/2” bit and a 3/4” outside diameter bushing so I need a 2.75” inside hole and a 4” outside diameter. The thickness would be best if more than 9/16” (that’s the height of the bushing). Did I pass the math test?

-

Hm I am not exactly sure. I have a router with a “Standard U.S. Guide Bushing Adapter” (Festool OF1010 EQ Imperial) but no guide bushing (or at least I don’t see one in the box). I have various straight shank bits in 3/8”, 1/2”, 3/4”. I need the finished inside diameter to be 2-1/2” and then the outside diameter to be 3-1/2” (or up to maybe 4”) and enough surface to make sure it sticks down real well.

-

-

Oh yeah that project - I need a circle router template so I can recess the nut a bit on the back of the plinth. Ideal template would be a circle on the outside too so I could use that outside edge to cut away the dampening rubber backing on the plinth.

-

Quite possible. I don’t compare their BAI’s - now you mention it, it wasn’t cheap. Then they figured out that another one of these can’t move itself. So maybe they will fetch a crane.