-

Posts

13,698 -

Joined

-

Last visited

-

Days Won

38

Content Type

Profiles

Forums

Events

Everything posted by luvdunhill

-

Go Nate!

-

Awesome! I have been working on building a trailer. Lots of fun, welding, grinding (but not so much fun painting - weather isn’t helping) and getting close to my deadline on Wed with the police to get an inspection and a VIN number for it. Then I need to get the mast cradle built. It’s going to look something like this but perhaps with a u-shaped liner out of hdpe plastic. Any other ideas?

-

When all you have is a RSA Predator?

-

Some super cool engineering going on here https://youtu.be/HR5oCVDta-w?t=462

-

Isn’t there an all black version?

-

Yeah, starting to get a feel for how much storage I would reasonably need for 4K or if it’s even worth it. Just using the Cloud Key thingy with 1TB for now.

-

I think it’s a nice clean install as well! This stuff is impressively hard. I think the countersink is the way to go..

-

.. because someone literally stole a car out of my driveway. Unfortunately for them, it had a tracker on it and we recovered it (the thief wasn’t inside) and now it’s the scene of a investigation of some sorts at an impound yard.

-

That detail was only in the part you had to read. I just looked at the pictures and gave my own opinion - is that what the kids do these days?

-

Nice! Would some small adhesive Teflon tape or something on the bottom help the drawers slide in easier? It seems if you apply the pull or push force on the end of the drawer it might bind up?

-

That looks nice!

-

“The ass end of this boat is so big” 😅

-

That’s awesome! We ended up getting stuck out on the cat today. We were in a spot of the lake where it was too narrow to tack effectively (the cat just doesn’t have the upwind performance of a monohull) and gain ground upwind.. the wind was about 10 mph straight down the middle with cliffs on each side. We got rescued by a more experienced sailor on a small john boat who said we were doomed to never get back up the lake. Heh.

-

At that point probably just best to use a hex head bolt and counter sink it…

-

Would the countersink diameter be say 3/8” - just enough to be able to get the bulk of the the square piece in? Yeah, I just need probably 4 or 5 holes.

-

I am working on my sailboat motor attachment and am using some 5/16” carriage bolts in the end of the transom so the heads are flush. The material will be something called Starboard, which is a marine HDPE plastic. It will be two 3/4” sheets put together. I am wondering how much material I need to make sure the square part of the bolts catch in the material? Should I just drill 5/16” or go 3/8”? The square part is .32” * .32” so the long diagonal of the square is .45”.

-

Here are the feet - there isn’t enough travel in them I think. I probably need another solution than the motor mount (male stud, rubber, male stud - which goes into the aluminum line footer and the shiny round circle thing on the top) idea which is stock for these VPI tables. There is a slight gap on purpose to suspect the table so it’s just decoupled via the rubber… the wood is just attached via glue dots to the underside of the plinth to hide the motor mounts.

-

-

Probably wing pins for kids first flight.

-

-

I have a defective driver IMG_2569.MOV

-

A bit of cart swapping to validate the arm board design. It has enough travel in the slots to work with the elusive DL-103PRO

-

Ok, did the bake off. [VPI mode=on]This REL is awful. It’s so bad that I am going to request a RMA. What was I thinking buying a 3D printed speaker? Bob Carver wins.[/VPI]

-

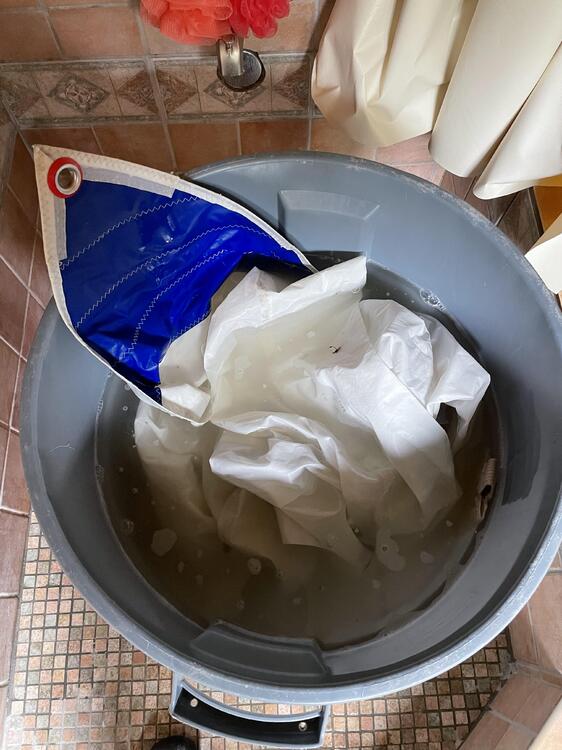

Washed the sails for the Laser and don’t think they will last much longer. Have one tear I have to patch and a batten pocket that is loosing its stitching. No clue if there is even a local sailmaker. I am guessing they are 20 years old, original to the boat.