-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Earspeakers

-

Doh - my mistake. The way the chassis is, it's difficult to read the legend. Handy to have spare boards to compare to, yes one is balance and the other offset. So what is balance then (did a search but it's not clear)? From the mask looks like it is a resistor between two FET's, maybe source resistor. I'll take a guess, updated version for adjustment Adjust PS test point to 580V DC headphone bias Adjust each amp board Offset pot to give 0VDC between + and - Adjust each amp board Balance pot to give 0VDC from either + (or -) to ground Correct?

-

Smoke test with amp sections, servo jumpers out. LED's no comma on, not good. Turned down variac, scratched head and found one channel had chassis wired +-15 backwards. Well, it's like a stage play, something has to go wrong. Easy fix and now it comes up with LED's. So today I'll adjust bias and such, double check me. Bias - test point on PSU, adjust 1M until 580V approximately Amp DC offset - Plug in jumper, use the two trim pots, fine and coarse, put DVM between + and - output pins on channel and adjust until approximately 0VDC between them (also - what is the jumper there for?) Then if all good, should be ready for test with headphones.

-

Fortunately I have a workplace with a big lab stock that is supportive of home electronics projects (as long as you're learning something). Quick trip into work ... fixed. We have bias!

-

Burp. Thanks. Speaking of which, what is the test point for, the bias?

-

Passed power supply smoke test. B+ and other supplies come up fine, except "Bias" has nothing on it. I see a reference here on this thread to a trimpot but it's not clear if that's on the PS or the ones on the amp boards. I don't have a trimpot on my power supply, but there is a mystery "1M three terminal spot near the output jack - is that for a 1M trim? It has a null symbol next to it (zero with a cross through it) which I took to mean no-op.

-

I found a source for a board set thanks, ordered the silicon (DAMN THAT HURT BAD), Penny and Giles pot (already numb from the silicon), and transformers. All the major parts. KGST smoke test today, KGSSHV in a month, Megatron about 3 months out, T2 by end of year.

-

I have a minty SR5 gold coming in next week, really looking forward to it. On testing I have a 207 I use with a long burn in period. Probably unnecessary, but I'm more comfortable than using expensive and/or out of manufacture headphones. You mean they just recently standardized this? Wow, that's unusual.

-

OK, they must be unusual. Small manufacturer.

-

Agree, but that's not what I'm saying, which is that it is unusual for a company to make changes (beyond bug fixes and small tweaks) in an existing product line. Of course they are evolving. Now we're talking about amps, maybe I wasn't clear but I was discussing headphones above. When circuits are involved as you well known parts and suppliers are much more volatile. In this case more variation is certainly possible for a small manufacturer who can't secure production agreements. This doesn't contradict my point though, as these are changes forces onto OEM's by suppliers. And yes with change oftentimes tweaks will slip in there too. Which is? Usually it's for reliability, manufacturability or cost reasons.

-

Speaking of which, I question the idea that Stax is extensively changing or even tweaking these production lines. I work in a similar business. While we're not as small as Stax by far, my product is the best scientific instrumentation in the world for this particular application. The devices are expensive ($100k), small (handheld), and specialized. I've also worked in similar industries so have experience in these kinds of production lines. FIrst, it would be very unusual for a company to change an existing line while in production, for several reasons. Motivation: there is none. Extensive R&D has gone into the existing design, who in their right mind would want to mess with it while trying to get product out to customers and make bills? Another way to say it, "don't mess with your cash cow" Difficulty: it's called "changing the airplane engines while in flight". Any change has potential side effects that only show up over time, who would do this on an existing production line? Staffing. R&D is always tasked for the next products, why revisit what is working and selling, and who has staff for that? Cost. Small production lines are expensive. Suppliers only want to do one, simple thing. Changing and making variations costs money and time. Certainly some things like coatings are not changed, except for necessity or good reason. Additionally it would be unlikely there would be great variation across the products for the basic components like film and coatings, it's too expensive (another topic would be production line design, which is how to create a myriad of seemingly different products that are actually just small variants of each other) Change sells. In other words, say you figure out an improvement, why would you give it away for free and unannounced on the existing line? You'd be crazy to do this, what you'd want to do is create a new product and trumpet the improvement. I've never seen it at any company that anything changes in production except for bug fixes, and reluctantly at that. Now note I'm not arguing whether people are hearing some kind of variation with the existing production line, but it's highly unlikely they've actually changed the line. If it is true, then it's highly likely to be sample variation. And if that was true, I'd say either Stax has poor control over production (seems unlikely), or that the headphones are so difficult to manufacture that there is an inherent degree of variability (this happens frequently, such as with silicon). And if that was true, the variability wouldn't be systematic, but instance based. Meaning a batch of headphones from one day would all be different. Systematic variation would have to be due to something like what the humidity was when they made the headphone (just an example, Stax appears to assemble in a 'near cleanroom' environment). Edit: I'll add that I happened to work in Japan for years in this industry, so have a sense of how the Japanese electronics industry works. Production engineering is mostly the same world wide, but for a Japanese only company like Stax I'd opine that it would be extremely unlikely for them to do this. Japanese companies are very conservative in this way, only the Germans are their equal.

-

I wouldn't hyperventilate if I was you. Spritz likes one kind of tone and found a pair that does that, you might like another. With Stax I'm not seeing that theres a holy grail of headphones. They're all much more alike than they're different, and the differences are subtle and basically come down to dialing in delicacy-punch and detail-warmth. Others may disagree, but that's what I'm hearing so far from some 10 different models in hand (pretty much the complete Lambda line). I'll have the latest 007 to compare to a mk 1 (carbon box) next week. Just a name people are using.

-

Ha, it is! The real name is "psychological adjustment". At least when it comes to Stax - dynamic drivers do actually loosen up. Ah, thanks. See below Bingo. Staxen sound more alike than different, but I'm hearing two axis which do change. One is detail - the lesser Stax don't seem to exactly lose detail, but it gets "fuzzed". Most obvious in the bass region in my experience - the contextual detail of the sound (i.e. a cello string) seems to be there, but it's fuzzed out compared to a better Stax. So there seems to be a sliding scale, the 207 being low on that, and the 009 and 4070 being high. Two is weight, presence or "meat" as you say. The 4070 has this the least in my experience so far, and yes the 009 has this quality (thin/delicate/airy), as does the 404LE. The new Lambda line has quite a bit of oompah. The Nova is a little unique, a bit on it's own as not too fuzzy, not too meaty, but warm and in the middle there. Now with the oomph the downside is that you lose the delicacy and some of the "air" of the other ones, which have a more refined sound. Anyhow that's what I'm hearing so far - love them all and listen all day while I work. I'll switch headphones for variety. And in terms of personal balance between these two axis which do I like best? I'd have to say the 404. Seems to get enough of everything just right, but I still don't want to listen to just one for 12 hours.

-

I'm already getting that! I have yet to meet the Stax I didn't like. Though the 4070 came dangerously close until I got to understand it. Next test is the Siggy coming in after repair.

-

Interesting, I have a new 009, with a new 007 (mk 3 I guess it's getting called) and 007 mk1 Carbon Box coming in. Will report what I hear.

-

Question on the 404's, I have a 404 Sig and 404LE and they BOTH have the red ring drivers. I had heard only the 404LE was red. Interesting things comparing up the Lambda line, Nova, Lambda sig, 404's and moderns.

-

Any advantage to either? Other than having to solder surface mount STN9360, which is easy as long as you have paste.

-

On the KGST, dumb question but the schematic is out of date and it should be documented here, it's either the A1486 or the STN9360, correct? Not both. I soldered the 9360 already so it's hard to see the traces, but it looks like they're both connected so it should be one or the other.

-

That was clever. Surprising how sensitive you guys are here, though the post obviously wasn't meant for experts. Well we don't really know, as there would be no evidence for deleted threads. I PM'd n_maher to please delete it but he's ignoring me, no doubt to punish me for the transgression.

-

-

A one tube simplified KGST IIRC, or something like that. I came across it here I thought, but am unable to find it again. Edit: I think this was it, but no elaboration. The layout files are up on Kevin's site, but no PDF schematic

-

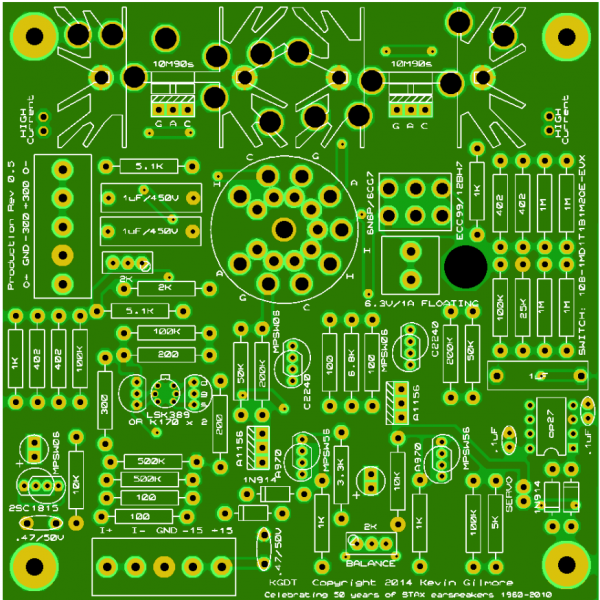

Got any boards? My goal is to build every Mafia Stax amp Here's a KGST, KGSSHV and Megatron being built simultaneously. KGST is practically done, T2 is on its way

-

Aladdin rebrand of 70's RCA? That's a new one. Thanks, I picked some up, I'm sure they'll be used somewhere in one of these amps. I'm assuming they're no different (sonically or other) from the 2SA970?

-

Thanks spritz. Rhetorical question: do the Mafia ever produce an amp that doesn't take an obsolete part? Well I do love your work; about to finish a KGST, a KGSSHV is partially done, a Megatron has been started, and just assembled the parts for the T2.

-

Edit: on overkill, it usually does come with downsides - cost and difficulty for one. But just a simple example, it's popular here to go for thick boards with 4oz traces. Good right? Yeah, until you try to solder them. Unless you have a Metcal station they're a pain to solder and take careful technique. You're more likely to end up with a cold joint, and for what? A thick board which still probably has a bit of that fiberglass bend in it. Anyhow ... I'm looking for a source of 2SA970 or MPSW56, can I trust these? http://www.ebay.com/itm/100pc-PNP-Transistor-2SA970-A970-TO-92-hfe-GR-Low-Noise-Audio-Amplifier-TOSHIBA-/140730909646 They do show a Toshiba box at least. Any other suggestions?

-

Yeah, I saw a post down below of somebody asking for advice on a $80 soldering station, rather than reply I thought to make a thread for a bunch of tips. I thought it was obvious that it wasn't for the experts. Since your a mod just delete the thread please.