-

Posts

8,475 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Everything posted by Pars

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

No. Footprint isn't close to the CP2500. Edit: BTW, anyone have a datasheet for the quad RK27? Can't find one, and Alps barely acknowledges they do a quad version of the RK27 (RK27114). -

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

As I feared, I can't go larger on the CP-2500 pad size without clearance issues between the pads noted in a previous post. Just a bad relationship between the 601 and 2500 pad locations. The only other think I could do would be to define the pads in the part as SMD pads, which I can control the x/y size and roundness on. You have to place these on both the top and bottom layer, and then drill them (or the slot) to get them to do a through hole part and plating. Might confuse Seeed. Here is the new gerber file(s) for the CP601 only board using 1.1mm drill on the pot holes. No change in board size or anything else. The dual board will not change size either once we have determined slot size. TKD 4CP601 only mod.pdf -

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

My intent was for the board to support both old and new pots. My concern is what is the convention for how much extra space to leave, i.e., what will the finished dimension of a 3.1 x 8 mm slot be after thru-plating and manufacture. I ran across the attached document the other day regarding IPC-2222 and IPC-2221 standards. Level A is for general production, and is what I think I should shoot for, but results in the most additional and the largest pad size. Unfortunately, it doesn't discuss slots. For the holes and pads for the CP601, the pins are 0.8mm. So, for Level A, the hole size would be: Minimum Hole Size = Maximum Lead Diameter + 0.25mm (for Level A of IPC-2222) 0.8 + 0.25 = 1.05. This isn't a std. drill, so 1.1. I already have this at 1mm, so can bump up. Pad Diameter = Minimum Hole Size + 0.1mm + 0.60mm (for Level A of IPC-2221) 1.1 + 0.1 + 0.6 = 1.8mm. Pads are already at 1.934, so good there. For the slots for the CP2500, I think I should bump them to 3.2 x 0.8mm If you could ask Seeed what the approx. finish dimension of a 3.1 x 0.8 and a 3.2 x 0.8mm slot would be, I'd appreciate it. I don't think I could go beyond the 3.2, as the pad would be getting too small, and there isn't room to bump the pad size up much, at least at Eagle's std. values. Let me know what you guys think. http://www.pcb-3d.com/knowledge-base/pth-dimensions -

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

If you can ask if they can measure one, that would be great. Thanks! -

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

OK, changed the slots from 2.6 x 0.8 to 3.1 x 0.8. MLA: can you check with your TKD contact regarding the pin size? Michael: can you check with seeed to see what the final dimension for a 3.1 x 0.8mm slot will be once plated? I was just guessing in terms of final dimension and how much additional size to plan for on the slots. For the CP601, the datasheet shows the pins at 0.8mm. On the part I created in Eagle, I used a 1mm drill, so we should be good there i think. I could up the drill to 1.1 if needed. Going any larger on the pad size would risk clearance issues between pins 4, 6, 7 and 9 on the CP601 and 2 of the output pads on the CP2500. -

I was looking at Thorsten Loesch's Analogue Addict's Phono Preamp, originally posted here, updated on the Pub in 2004/2006 or so, and then again on diyhifi.org in 2012. I can't find anything beyond what is in the thread there (all links/images are dead). Seems interesting though, and pretty cheap to build. It does have an add-on portion for MC, but is geared towards MM carts. Thorsten advises P-P build instead of doing a PCB, and thinks that deadbug on copper would be the best way to do this. Something I've never done before. This needs a pair of OPA637s, which at current pricing I would be reluctant to solder directly to. If anyone happens to have more up to date info on this I'd appreciate anything I could get. Apparently he had made parts recommendations (based on more current parts), etc. I sent him a PM on diyhifi, but I would be surprised if he answers it. Maybe do a teflon PCB

-

I'd be interested in some 2SJ74s depending on grade. Or maybe some 2SK170s in addition, though I still have a number of those in BL grade IIRC.

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

For the dual CP401/CP2500 pot board: I went downstairs and measured the pins on a 2CP2511 I have (never used), and the width on the pins was 3mm, not the 2.5mm shown in the datasheet. The datasheet you guys sent does show 2.5mm, but an older datasheet that I had shows 3mm, so they must have changed these at some point. I think I should enlarge the slots to 3.1 x 0.8mm just in case, and to accommodate older pots. Thoughts? I attached both datasheets. TKD cp2500ps-e.pdf 2CP2511.pdf -

I think I would prefer to stick with SS. My cart currently is an AT 440mla MM, 4mV so I don't need anything that will handle a LO MC. I was looking at AudioSector, but that one appears to be geared towards LO MC. The table is my old Thorens 320, so nothing special there.

-

I must be dense... the "Y" part

-

Seems to not be finished... What are thoughts on RJM's stuff on diyaudio, particularly the phonoclone?

-

Yep. 27" wheels are ISO 630 while 700c are ISO 622, so you will need 4mm more reach on the brakes. Sheldon Brown (RIP) has a section on his site regarding cold setting. Your Panasonic was probably already 126mm for 6 speed. Spreading a 120mm 5-speed frame requires a bit more care, but you are still only opening it 5mm per side.

-

You can use some appropriate shoes (non-cleated) with your current toeclip/strap setup. Adidas Samba soccer shoes apparently work pretty well. The old Avocet shoes were great though (model 30), used to win RAAM in the '80s. As for the wheels, what kind of hubs? You could rebuild them with 700c clincher rims (Velocity, Mavic, etc.), new stainless spokes, etc. This would open up your tire selection, though you can still get some tires in 27", such as Panaracer Pasela. It wouldn't be much of a stretch to spread the rear to 126mm for std. 6 speed / ultra 7 freewheels. You would have to replace the axle for the rear hub with the appropriate length and increase the spacers a bit for that. The frame could be cold set to 130mm for a modern group also, but getting harder to find in silver alloy. Stuff like what jose just bought doesn't look at home on a vintage frame. Wiggle / Ribble / Probikekit, etc. have pretty good pricing on many groups, but you will also need wheels. Or grabbing a donor bike would be the most cost effective. Should all be English (BSC) threading. Many time you can use the existing crankset, though the modern ramped ring ones will shift a bit better.

-

Any recs for a decent cheap phono stage? DIY fine as well.

-

Very tasteful build John!

-

Great news on Andrew!

-

Strange... I also have an original Dynalo (built on one of Justin's headamp boards, back when he sold them), plus another one that is built on rev. b/c boards, but powered with an Elpac wallwart. While I still don't think the SUSY version sounds massively better, it is at least as good, and certainly not inferior. My SUSY is using the FET input (K179/J74), and a 10K pot. What is your biasing on the SUSY? Mine is using +/-16V supply IIRC, and running around 17mA. I don't recall what I have in there for resistors, maybe 301R? Also, I recall that I was not impressed with the SUSY initially, but had some pot wiring problems. Once corrected, it sounds very good.

-

Dan Gardner was the one who actually did the Rev. b and Rev. c boards. He isn't on head-case, but you might be able to contact him on that other site (you know the one). I don't think I ever had the gerbers and I don't know if Kevin ever did or not. Dan might still have them. I think his user name there was dgardner, but I could be mis-remembering.

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

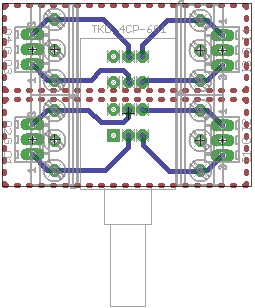

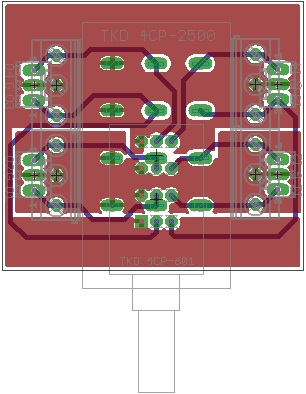

Here is the 4CP601 only board that Michael requested, along with the Gerbers for both the dual CP601/CP2500 board and the CP601-only board. Change the extension from .pdf to .zip (HC won't upload zip files). TKD 4CP601 only.pdf TKD 4CP board.pdf -

Happy Birthday Jack! Hope all is going great, and you have a great one!

-

Stupid question time (don't slap me!). For a dual secondary transformer, could you wire the secondaries together in phase (1 end of one secondary to the opposite phase end of the other secondary), and use that as the "center tap"? Va 0a Vb 0b Tying 0a to Vb for the CT...

-

Hmm, hadn't checked in awhile 125.7 up / 23.7 down

-

lead free is bollocks, based on bollocks, IMHO

-

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself

Center image is a 4CP-601. Right image is a 4CP-2500. As far as the board layout goes, do you guys more experienced with PCBs and fabs think that the 0.1mm oversize on the slots is enough, particularly considering thru-plating? Or should I go a bit bigger. I haven't measured the pin size on the 2CP2500 I have downstairs, and was going by the data sheet. EDIT: Michael, I want to adjust the board size and spacing to make it as small as possible. I assume the last one I posted, with the split ground planes, is the one that all of you want? -

TKD 4CP-601 & 4CP-2500 4-gang volume pot and PCB GB

Pars replied to mwl168's topic in Do It Yourself