-

Posts

8,503 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Events

Everything posted by Pars

-

I've been using the "Mark items as read" at the bottom every day or so, which helps.

-

Maybe not in the same league (but maybe they are?) Odyssey Stratos. Like this one: My link Or if you wanted a hybrid (tube front-end), Counterpoint SA-100 or SA-220. Here is an upgraded one: My link EDIT: Odyssey is Symphonic Line RG1 IIRC

-

Apple in talks to improve sound quality of music downloads

Pars replied to Grahame's topic in Miscellaneous

If that is typical of the quality of the forum at gizmodo, it makes head-fi look inviting Bunch of whiny bitches... -

I always thought that 6Morons was an apt name for that site. This confirms it.

-

I think those are the prototype through-hole files that I have. They don't match the gb board exactly. I tried contacting Jacob, but no response. I used the contact link through HC... not sure if that is a PM or email. If anyone has his email address, we could use the eagle files for both versions. Any other documentation he might have (BOM for the SMD version, etc.) would be gravy. I asked Kevin and he doesn't have them.

-

Apple in talks to improve sound quality of music downloads

Pars replied to Grahame's topic in Miscellaneous

Doesn't take much translation: buy more (new) downloads, and oh yeah, you'll need some new hardware too As far as they're concerned... win-win -

Gotcha. PM incoming...

-

Happy Birthday!

-

^ probably the best compromise if you want to be able to run either way and there isn't a more elegant solution. Once I do some listening to it, I would probably decide I liked it one way or the other anyway and tweak it for that. End of problem. The FET instability is more worrisome however. I've kinda put this down for awhile, but am interested to see what you encounter when you get a board (or more) built up and start looking at it.

-

Interesting post from Allan Wright on diyhifi regarding the apparently religious use of the 5532/5534 in digital equipment output stages... My link

-

I'm sure it does, and that is the reason for an opamp that can run from 30V rails. I still prefer to get offset as low as possible before relying on the servo for clean-up. And 160mV doesn't seem low to me. I can adjust it out via the pots, but there wouldn't be any quick switch between the two modes. I know Kevin told me you would need the servo for the local feedback option, so maybe there isn't any way to balance things out for low offset (without servo) for either feedback method simultaneously.

-

I usually used TL071s on 15V rails, like all Dynalos.

-

How are you guys coming along on the production version Doug? I was just over at my brother's briefly yesterday, and he is still enjoying his immensely. Thanks for letting me in on the proto phase!

-

Tested it out this morning. A slight amount of tube hiss (barely audible with head < 12" from speaker), but no hum. Gone at all gain settings. And this is with the tubes cold, so it should decrease after a bit of warm up. I need to publicly thank Alan (VivaVee on diyaudio) for his help in finding this. He is the same person who helped me fix my brother's power amp as well. Good guy.

-

Please fix that! Make it stop, please...

-

Looks decent. I don't have any experience with them, but Ayoue seems to be well thought of. Price looks good as well. I would think this would be much easier than the flood and suck method, particularly in clean up Another plus for being able to localize the heat rather than having to heat the whole board up (toaster oven).

-

Happy Birthday Colin!

-

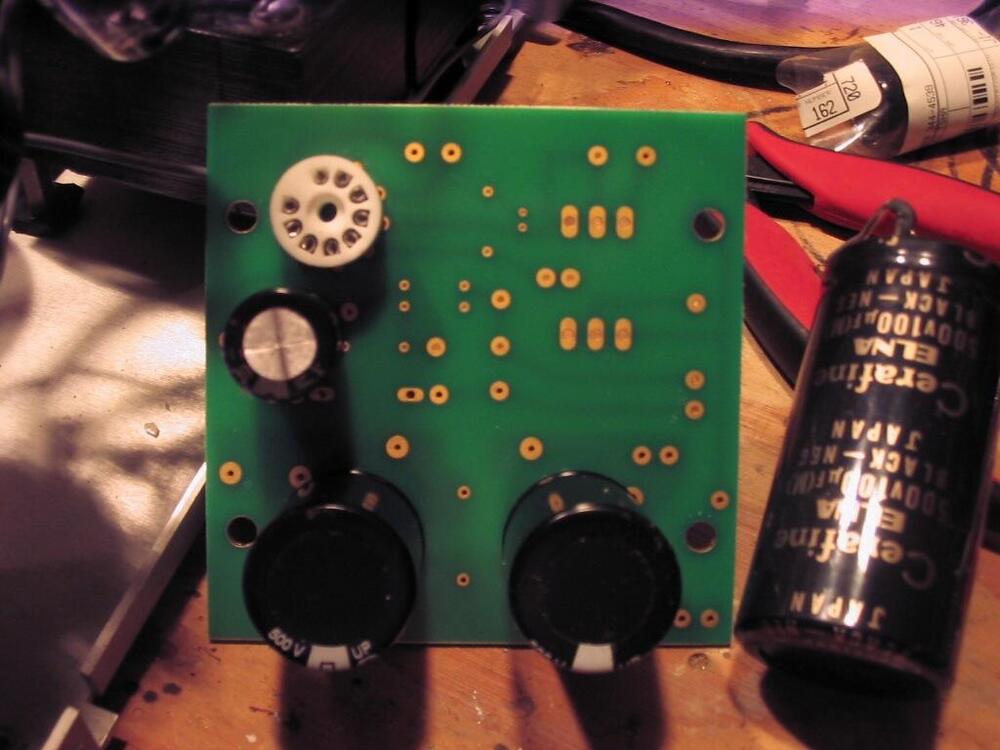

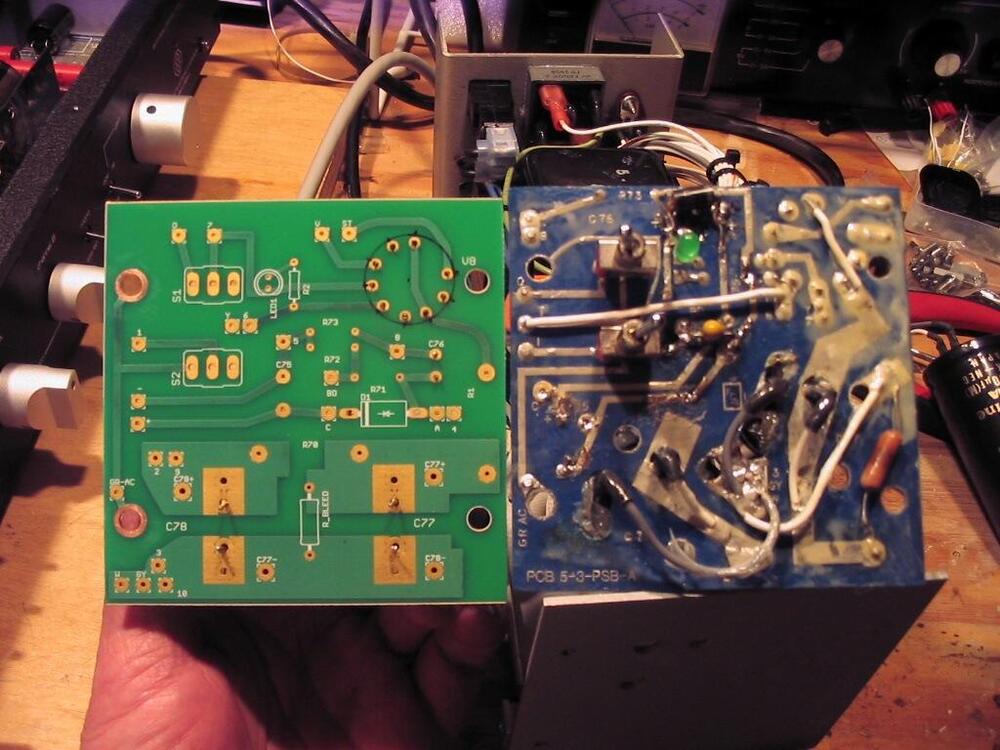

Still trying to decide whether to swap out the PCB with one I did a couple of years ago. Looking it over again, it has a couple of minor errors on it, but I think I can work around them. I didn't check the stock tube layouts in Eagle, and this turned out a bit small on the pad circle. This socket will fit, but I'd rather use the Azuma socket that is in there now, and it doesn't fit. I also don't think I will put the two 500V Cerafines like the one pictured in, but will use the Panasonics pictured on the board. The old board is coated with Q-Dope... not dirt http://i883.photobucket.com/albums/ac31/Pars1746/Counterpoint%20SA5/new_PSU_PCB.jpg http://i883.photobucket.com/albums/ac31/Pars1746/Counterpoint%20SA5/PSU_PCBs.jpg

-

Happy Birthday Steve! Glad I didn't open this thread at work

-

Looked like that to me too, curled up on the sigma22... it doesn't run THAT hot! I see you have the AA HPA in prominence as well still

-

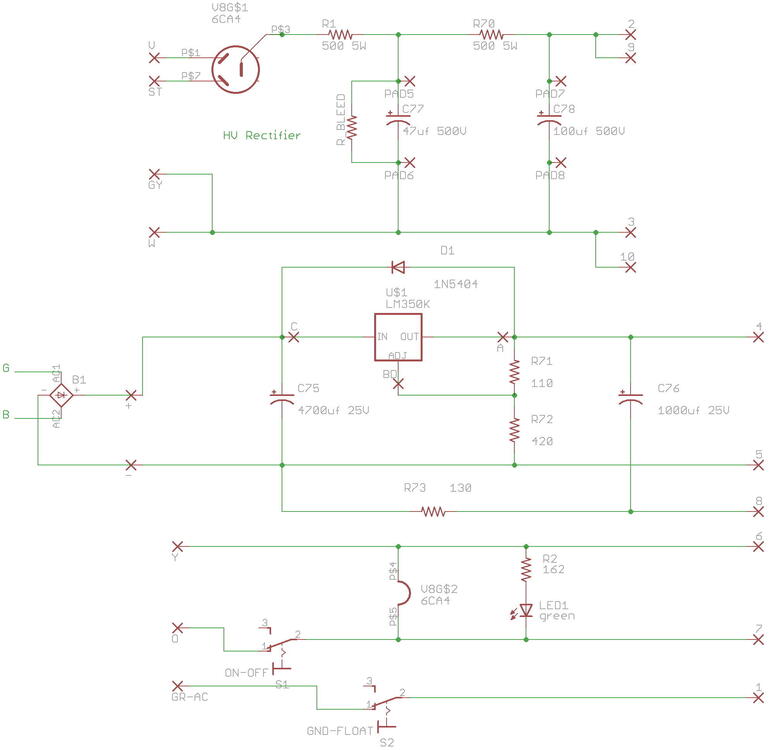

Sorry, fresh out of scotch Probably good advice. Point to point isn't likely to happen in this given the form factor (think '80s Threshold preamps with their brick PSUs; then think of stuffing a full tube pre and tube rectified PSU into that form factor) and resale value, so I pretty much have to deal with what I have. Corrected (for the .1 version) schematic

-

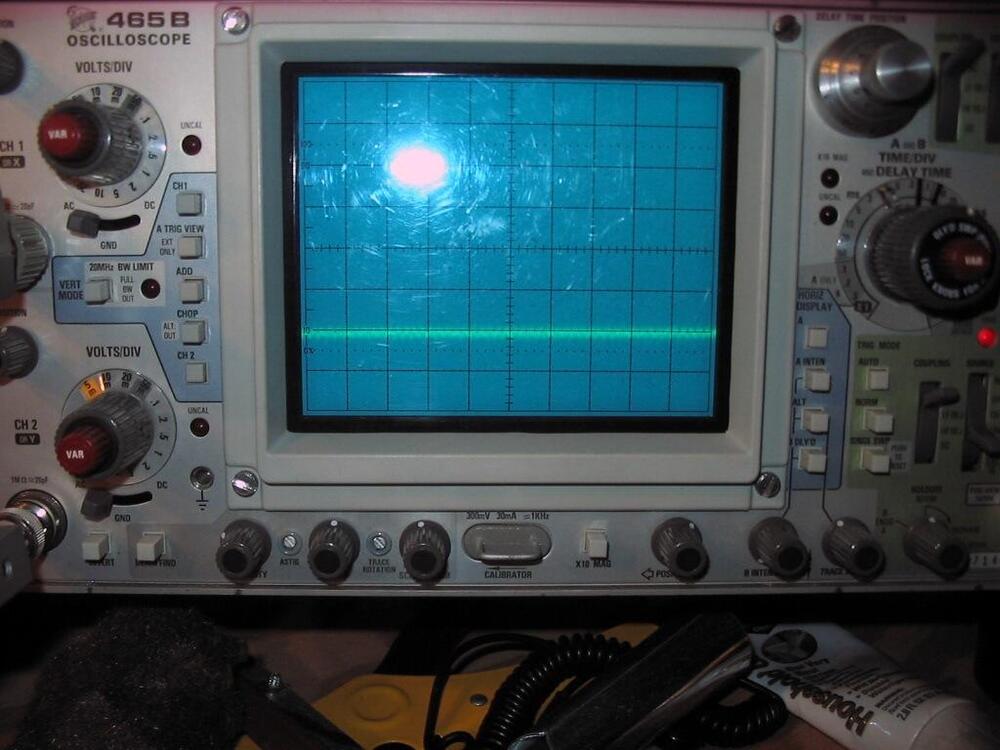

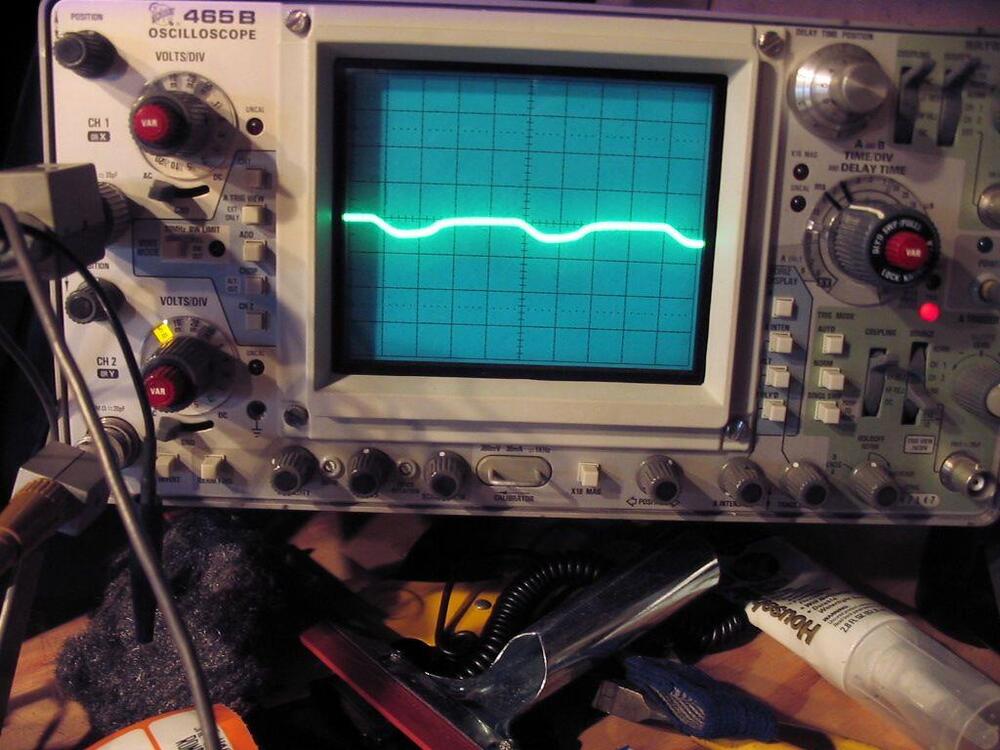

I've been messing around with a Counterpoint preamp I have owned for several years on and off. It's always had a slight amount of hum, not real bad, but it bothered me. Over the years I've managed to make it worse, and then much better, but never quite gone completely. After dealings with a couple of former service techs on diyaudio, I finally decided to try once again to rectify this. I was prodded to look at the PSU, particularly the heater supply (I'd already done some work and parts replacement in the HV section). Looking at the heaters, I had recalled seeing some ripple on them back when I rewired the umbilical (both before and after). About 50mV of ripple at 2x line frequency (120Hz). 50mV/division (x10 probe). After being pointed in the direction of board layout, I noticed the following (once it sunk in): C is the lead to the input of the LM350K regulator. It is wired right next to the input (+) from the bridge rectifier, putting raw DC in. Moved to past the filter cap (C75). 5 is the output (-) to the tube heaters in the amp chassis. It is also wired prior to the cap (C75) One more change not shown in the pic: R72 (green rectangle shows location) needed to have the bottom end rotated 90º counterclockwise so it returned beyond C75. After making these changes, the net result: Same 50mV/division, timebase is extended out a bit in this pic. Designer seems to have a problem common to many: PSU design. And this is a high-end preamp from the '80s, lauded by Arthur Salvatore, yada yada. Such simple errors, but it surprised me as the changes involved moving components/wires along signal paths that are unbroken and electrically connected. The previous connections weren't wrong, they just weren't really right. Noise was being fed into the regulator because its feed was taken before the filter cap, not after it. The output (pin 5) was also being taken before the cap, not after. Same with the adjust pin return resistor (R72). One other thing not done originally: per the datasheet, the addition of a 5 cent capacitor across the adjust resistor buys you 15dB better noise rejection. Implemented now. I haven't listened to it yet, but anticipate that it should be gone