-

Posts

1,464 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

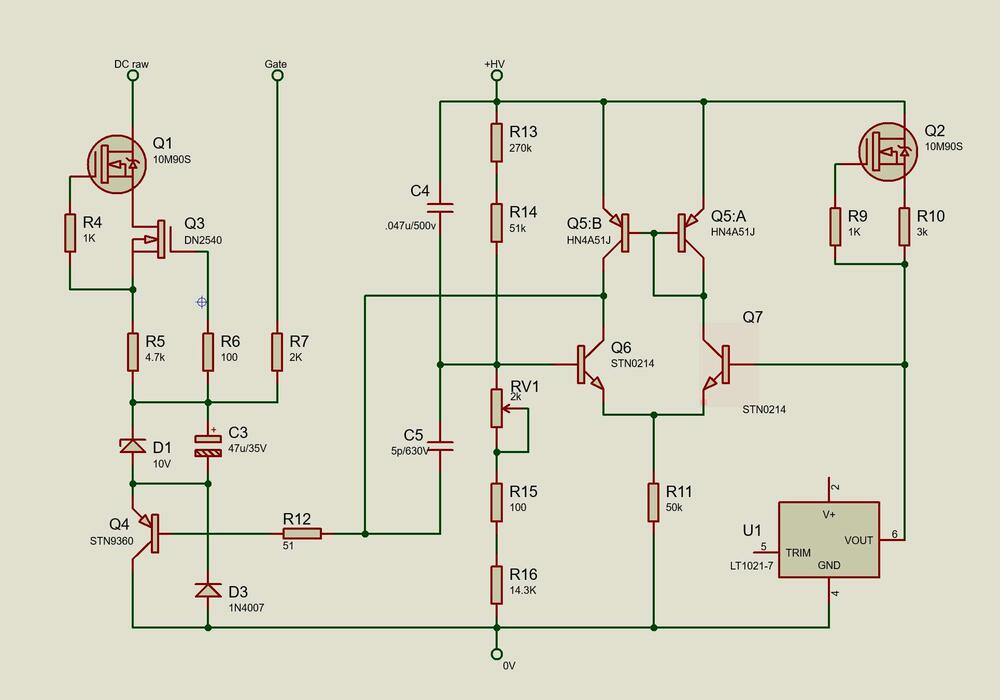

Here a schematics. Four connections to main board. The raw DC is taken before the two 10m90s current limiters. Better would be after the limiters but no free hole for it. Works like a charm I wrote. Yes, charming it is when it works. When it suddenly stops working and give 13V instead of 150V – that is more annoying than charming. It has happened two times so far since my last post. Not sure what’s wrong but I change Q5 (dual small PNP) with a new piece and then it works for couple of hours. Now I’m just waiting for the next breakdown. Suggestions what might cause the problem are welcome!

-

Almost a year has elapsed since I reduced the 300V section to 150V. The amplifier has worked well, and I haven’t noticed any sonically differences. So, some time ago I decided to make the same change on my modified T2 and its original T2 PSU we have at our summer cottage. But unfortunately, it was not possible to bring the voltage down to 150V. 190 – 200V was the lowest I got. I’ve had a Golden Reference power supply for the T2 in mind for a long time. Now I had to do something the get the desired 150V section with the original T2 PSU… Made a daughter board with GRHV regulator for the original T2 PSU. Works like a charm.

-

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

My impression is that this is intended to be a Muscle CFA3. You probably want 3U – at least. No V12 engine in a Volkswagen Beetle. -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

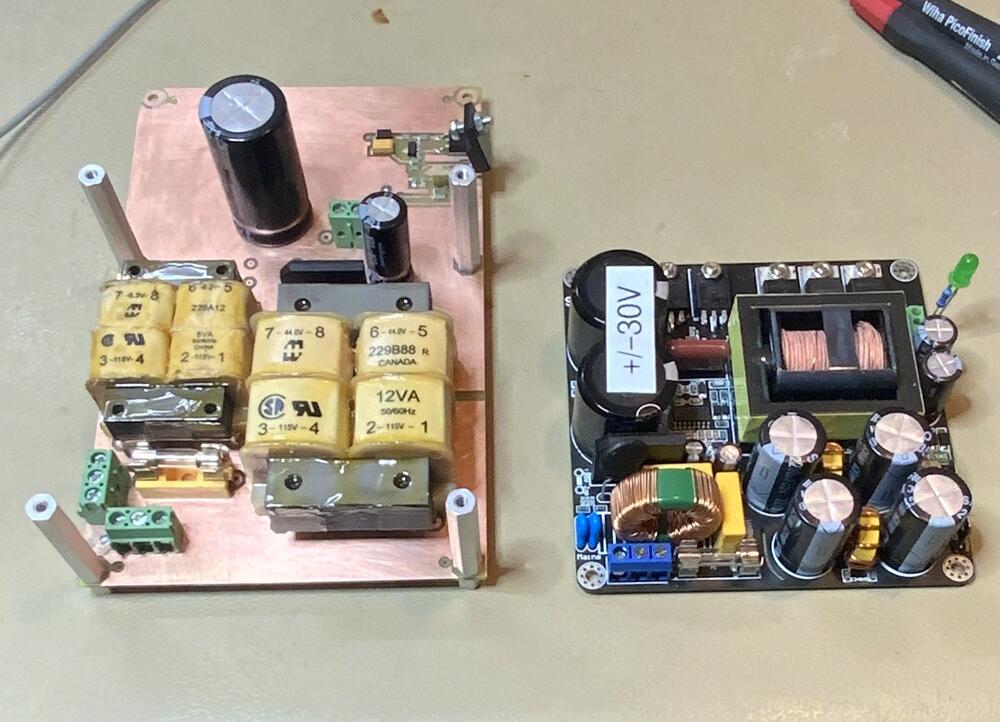

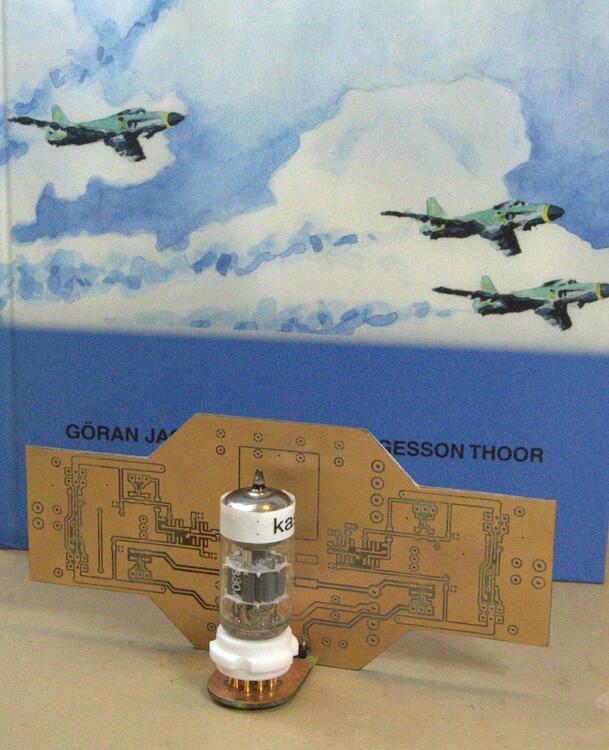

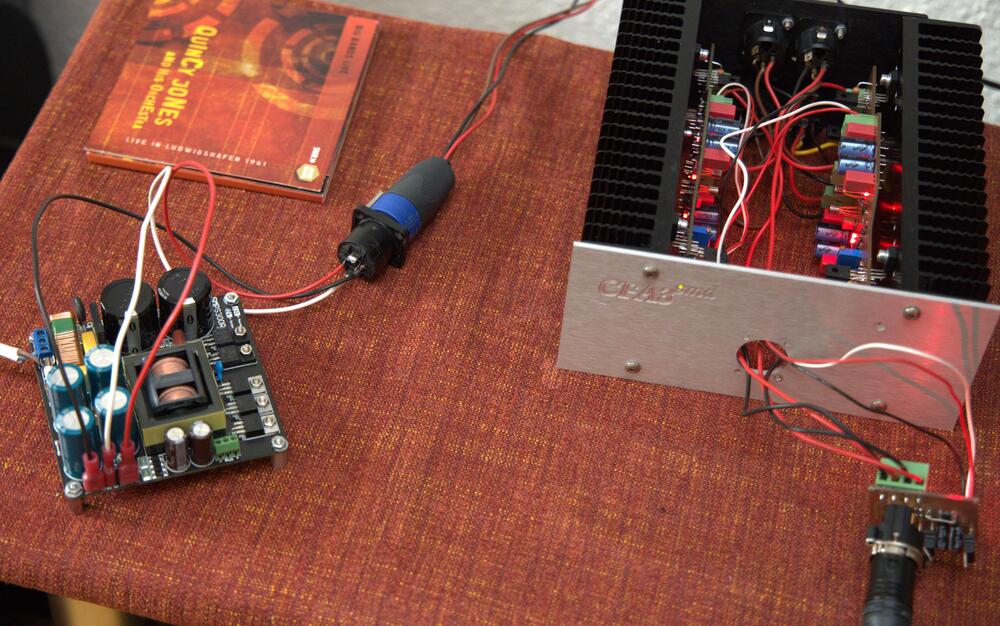

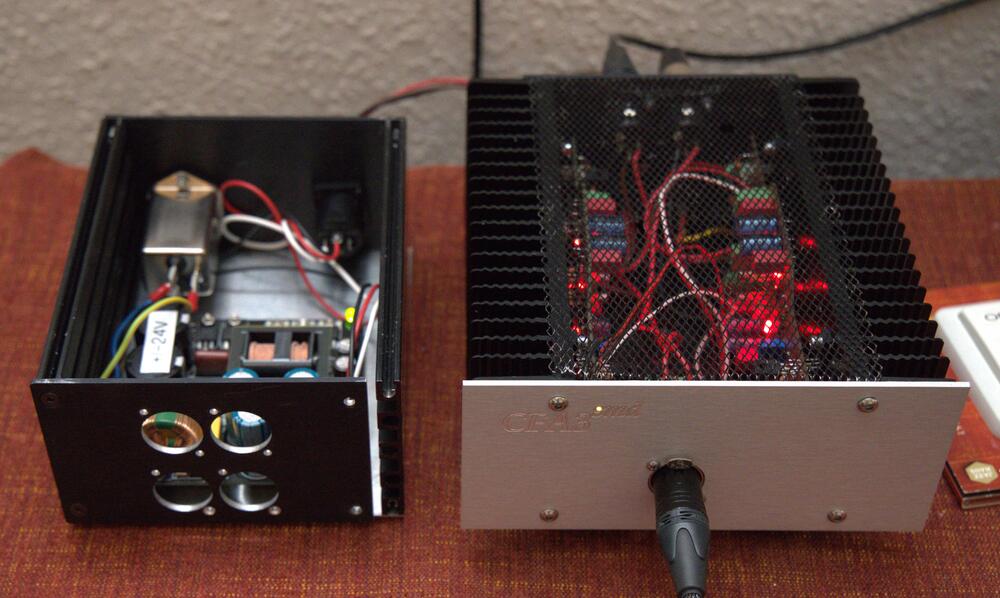

Some progress with Tube Hybrid(something). PSU; left – Board with filament transformer and transformer for GRHV style regulator (+100V). To the right is Connex SMPS, put it in top of the first board and you have PSU with 6.3VAC, +100VDC and +/-30VDC. Amplifier board with a tube daughter board. The required -5V is done on the amplifier board with a smd 7905 and a few capacitors. Will it work? Who knows? -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

I guess those big things stand some heat. Why not just remove the throttle plate (vbe multiplier)... and feel the speed. -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

Thanks. According datasheet they are to3p devices - a bit bigger than mjf1503x. -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

The output transistors are 2sa1860 and 2sc4886 - right? -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

Looks like transistor at heat sink are TO-220. Aren't the output transistors something bigger – TO-3P - so the board need a stretch? -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

Now I’ve listened to CFA3smd something with switched mode power supply for almost 2 months and I’m happy with it. So, no plan for a golden reference supply. I’m too lazy and I think the switched power supply is good enough for me. Next “project” is how to power a Tube Hybrid. The Hybrid needs +100V, -5V and 6.3VAC for the tubes. The PSU has to be rebuilt. The amplifier board is finished, in theory… -

Maybe DN2535 (max voltage 350V) will work. Main difference to DN2540 (max voltage 400V) seems to be the maximum voltage. In stock at Mouser for roughly the same price as DN2540.

-

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

thanks -

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

-

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

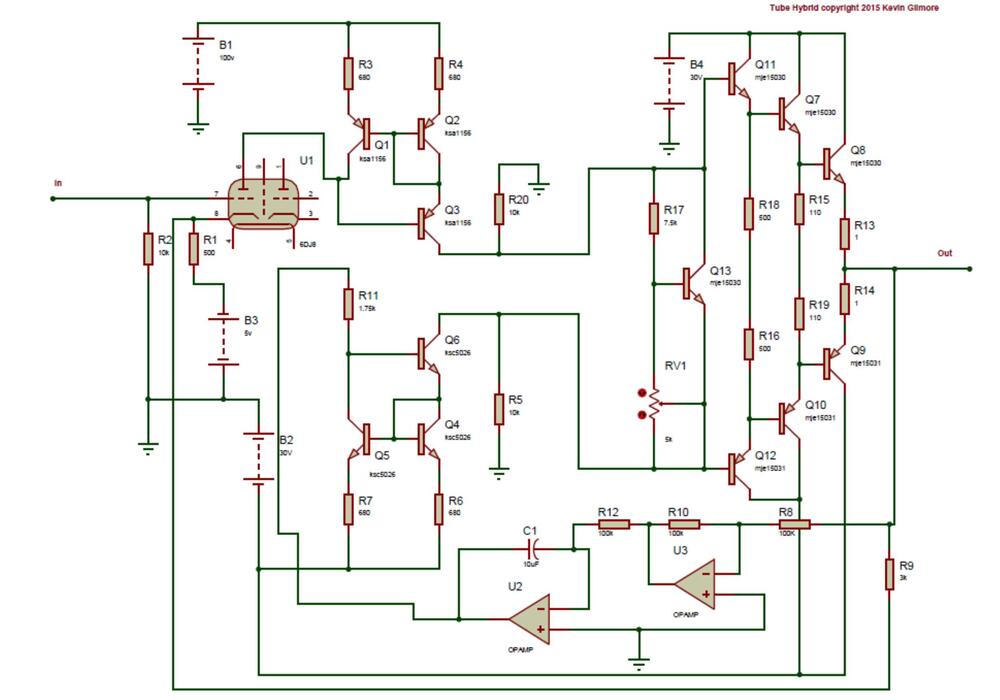

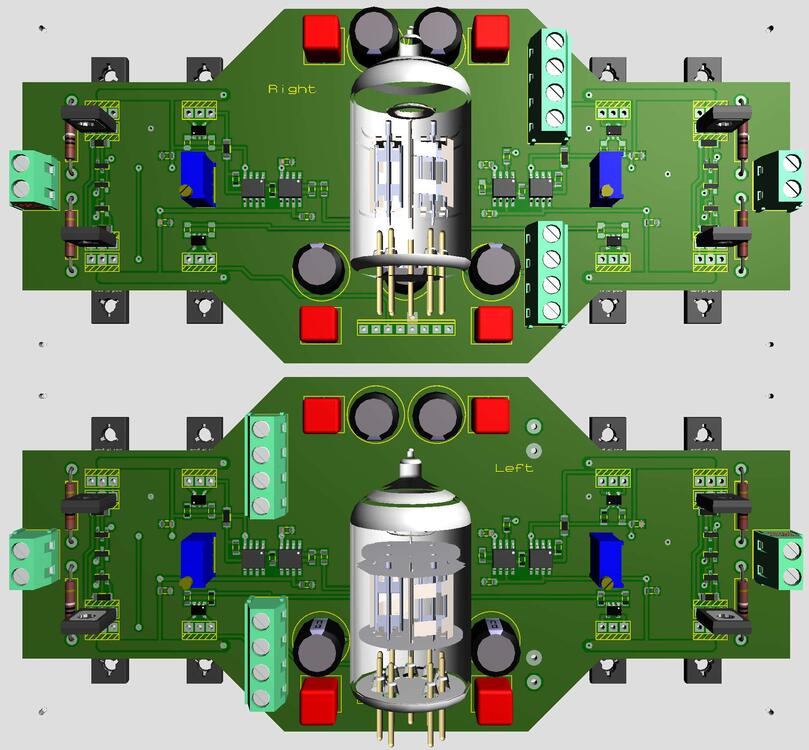

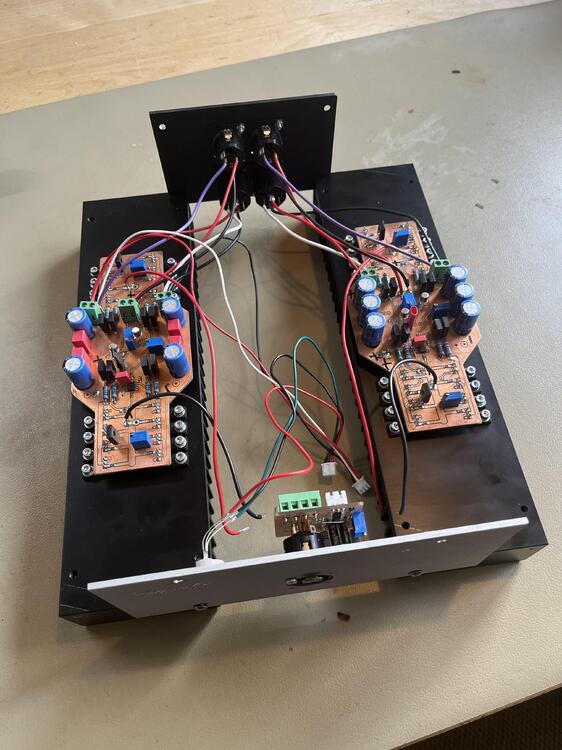

Some folks “over there” seem interested in Kevin’s Tube Hybrid. So, I removed a lot of small components from CFA3smd boards and replaced them with dual triode and double op amp. All according to info I found in Kevin’s library on google drive. It should all fit in the same box as CFA3smd. PSU needs additional voltages, 5- and 100-volt sections and filament for tubes. -

I'm satisfied with 400V. Started with 500V ten years ago. Reduced to 450V a couple of years ago and now 400V for all my electrostatics, including DIY T2. You might try stn0214. It's surface mounted piece, but it can be soldered in standing on the ksc5026 pads.

-

-

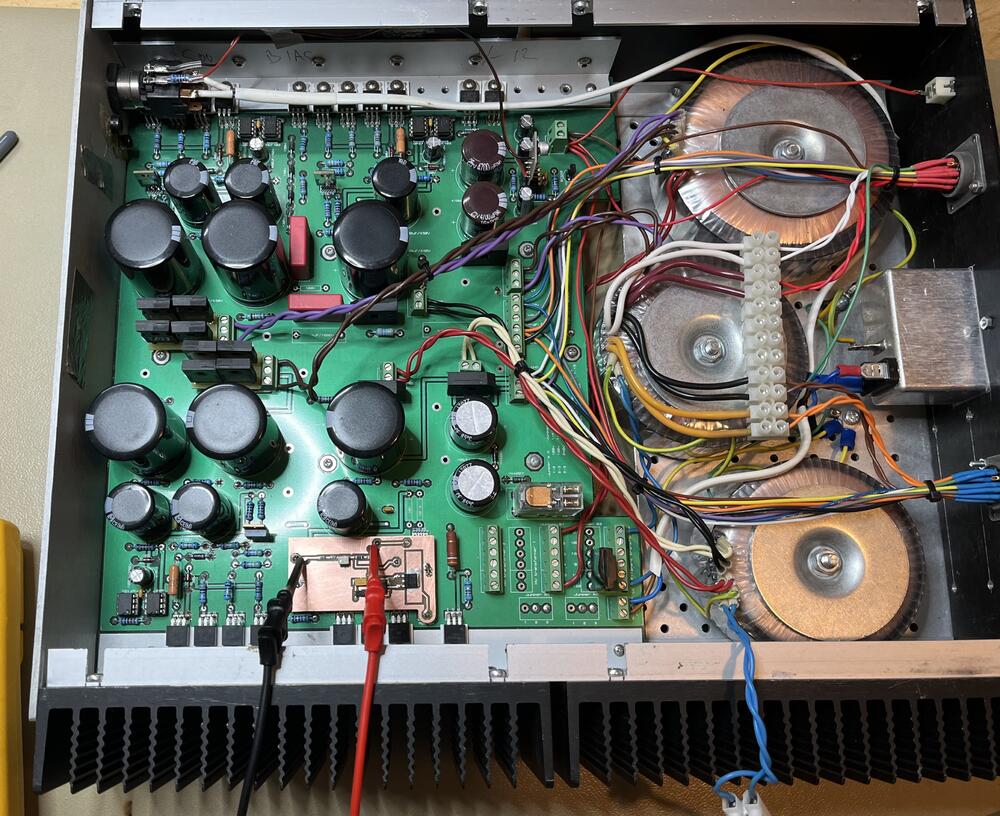

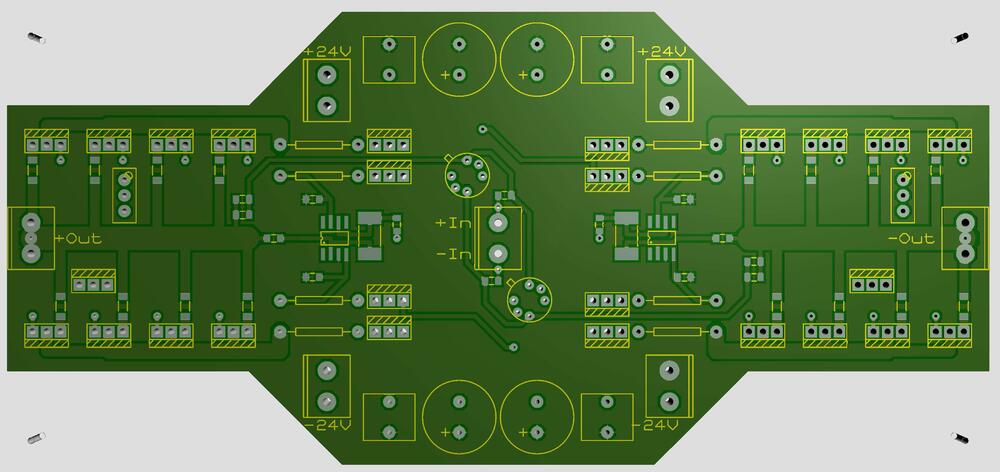

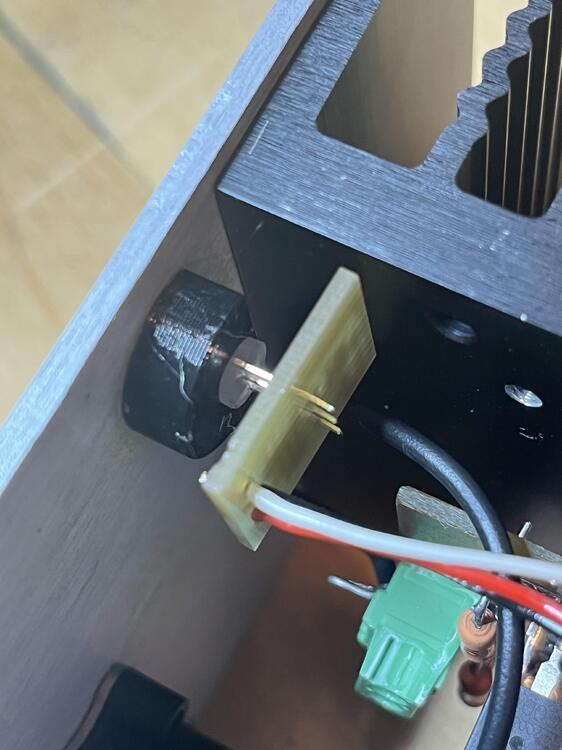

It’s a balanced board. Inputs in center. Outputs at far right and far left. Positive rail at top edge and negative rail at bottom. Dynahi boards mounted to 80 mm x 300 mm heat sinks. Here I’ve removed upper screws holding front and back plates to heat sinks and then “unfolded” for maintenance. To make it possible to unfold the wires are made “to long” when folded and then it looks like a snake nest. This is an Only DIY version, not to be sold... I hope this makes it a bit clearer.

-

Seems windows don’t like us. Try click and rightclick you around until you find a way. Alternative go direct to the Gilmore source on Google Drive, click on first link and scroll down to you find protect3.zip.. Lots of good stuff here. Sometimes it’s tricky to find the information you need, but it’s there – somewhere.

-

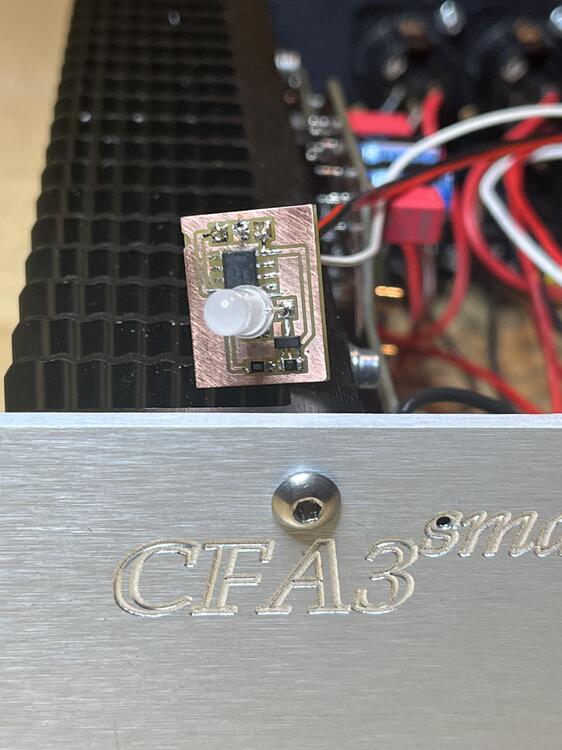

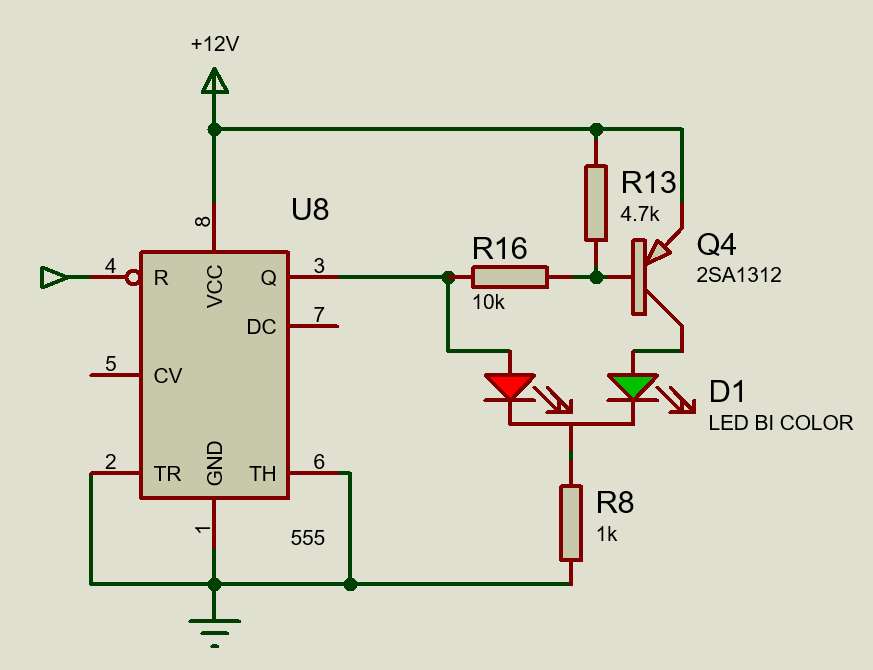

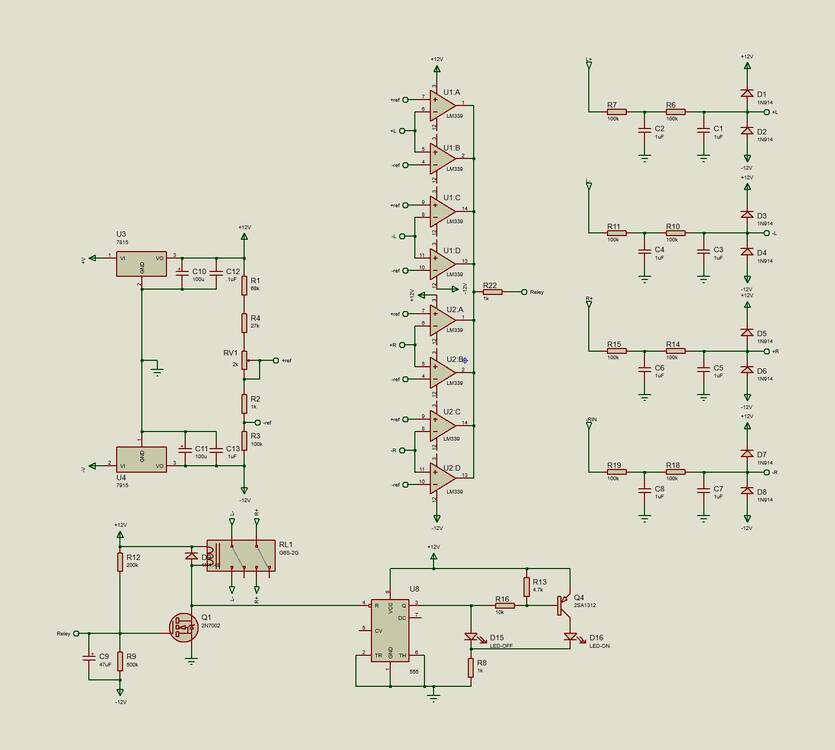

It’s not very clear in the schematic above (I’m sorry), but D15 and D16 is a bi color LED with common cathode. Below the two LEDs are replaced with a bi color device. The purpose of the 555 is make the LED red when relay is disengaged and green when engaged. This is the way I found to get a simple red/green indicator working.

-

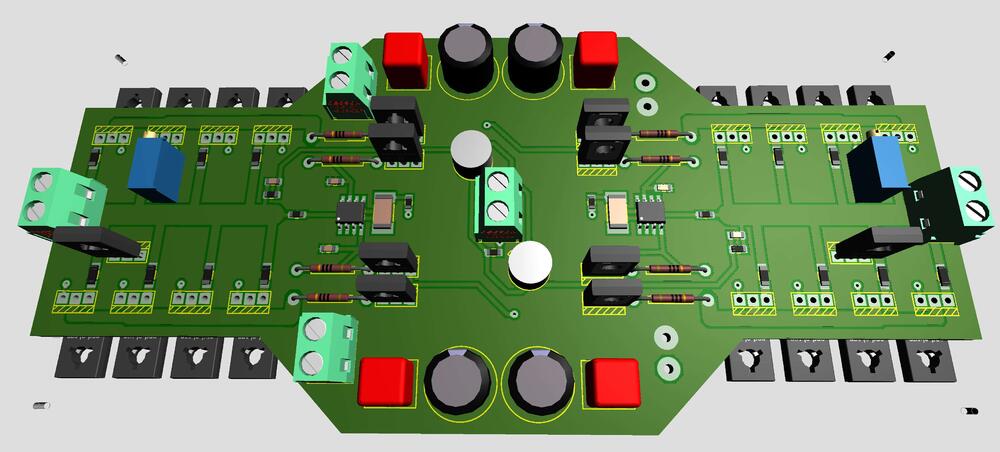

A slightly reworked “Dynahi smd” board. Balance and offset trimmers removed. Now servo on each side that bring the offsets to ground potential. Bias trimmers moved to north for easier accessibility “in flight”. This is a "solder and play" board. No set up procedures required, except to turn bias trimmers to desired bias. At least that’s the idea.

-

My latest schematics - essentially a copy of the original. See this Protector 3 gerbers by Kevin Gilmore protect3.zip.

-

Yes, of course, stn0214. My mistake – I shouldn't rely on memory solely.

-

If it’s ksc5026 in KGSShv style power supply you can probably use stn0216 stn0214 intstead. Solder it standing on the to126 pads (might be to220 pads on your board?). Power dissipation there is something like 40 – 60 mW, I think.

-