-

Posts

1,464 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

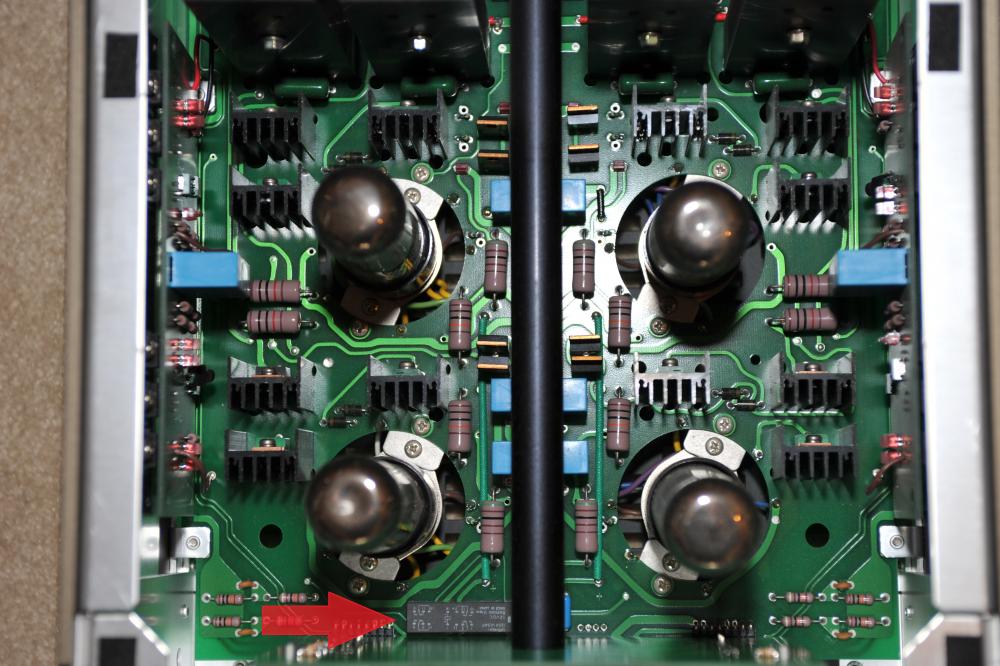

Running the Mini Dynalo as I did above need heat sinks. Measured 250 deg. Fahrenheit. I believe Kerry and Kevin have some modification in mind.

-

-

So far, got them in February this year, the EML 20B-V4 have treated me well. But I don’t think I know enough to judge their overall quality and reliability.

-

Well, I’m running out of ammunition. Blind shot, could it be the 12V Zener that’s the problem? One way to proceed is George’s advice. Also want to quote Kerry, from The ultimate DIY? A Stax SRM-T2!

-

Nice build indeed. Really like the look of the power switch, espacailly with darker background. Glad you are going for KGBH. Now 20% off. Join the RASS movement.

-

If 17V at pin 3 (katode) 10M90S and 1.77V cross 4.7K resistor than you probably have almost 0V at the emitter of STN9360. My next long shot is at the STN936.

-

Long shot, but a flipped 1N4007 cross STN9360 will probably give the same result as you have.

-

Great, will it cure excessive terrorizing posting as well?

-

Amazing how good he is at getting responses!

-

Great you found the opto servo working well. In my Grounded Grid I’ve omitted offset trimmer and its associated resistor and that works great. For time being I consider the opto servo as the preferred one.

-

Indeed, a really nice upgrade! I use old chassis for new boards. I even desolder components and move them to the new version/board. That way I keep number of amplifiers constant, an agreement with my partner.

-

-

Wow! I also want one.

-

An IR remote volume control. Not built today, but brought it out in daylight today after four years. Need a volume control for AMB y3. Might work a little bit more with, it looks like …… .

-

-

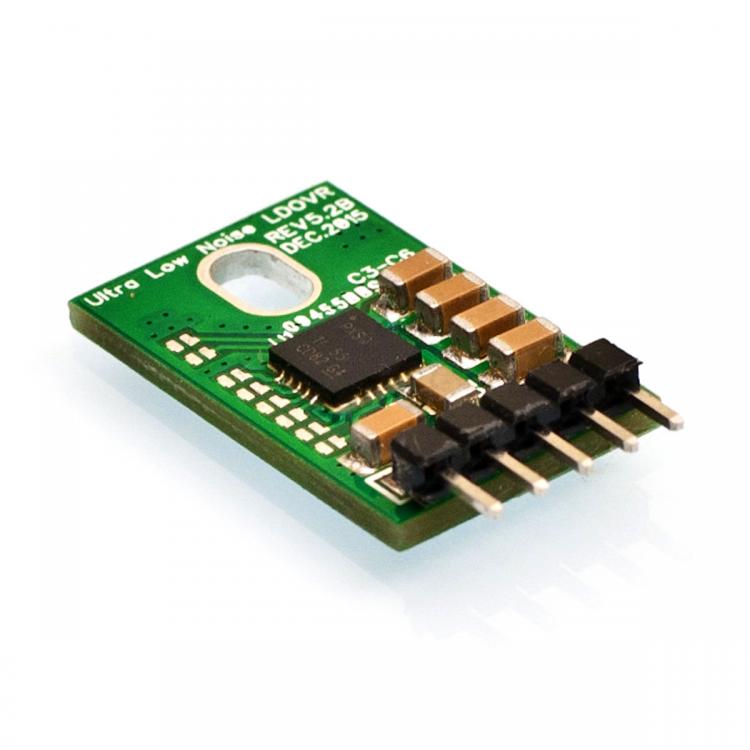

TPS7A47/33 - 20 pins and thermal pad within 5mm x 5mm and need of heat sink. Seems to be a tricky one for most of us. Lovely work!

-

While experimenting - shut down HV with LV remaining and see what happens.

-

Anyone have a spice model of GRLV to share?

-

Thanks for info, Birgir. I’ve been thinking about the possibility to use some kind of relay in a future T2. Not sure that Omron G6A equivalent is the one to use, but if Stax can - I could try...

-

-

aluminium allergy Don't like make comments on how things sound or perform. Anyhow, after several hours of listening, I like y3 significant better than my NAD M51 and Benchmark DAC2. OK, I did build it myself which might explain my view. But it's no question that y3 is a high performance DAC and is despite some SMD parts relatively easy to build.

-

A working y3. All right, need a nice chassis. Indeed, a very impressive DAC from AMB. I’m very grateful for all the work that have been put in this project. Thanks a lot Ti.

-

Happy Birthday, Kerry!

-

Downloaded and installed Fusion 360. Have tried it for a short while (raining today). And maybe…. even me might manage to do something with it. Thanks for the tip.