-

Posts

1,464 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

-

Very much appreciated.

-

Had a pupil once that suggested mV stands for miniVolt. Cute isn’t? Anyhow - this is what I’ve done today: Current in mA – milliampere. Regarding Watt. You know what Miniwatt is?

-

= 3000 minivolts

-

Positive: 10uF, 1uF, 4x10uF and 5x0ohm resistors for voltage setting. Negative: 10uF, 1uF, 4x10uF and 89ohms, AOT, 1M43, 10nF.

-

Just switching to 100 watts resistors will that protect us from exploding output board and associated PSUs?

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

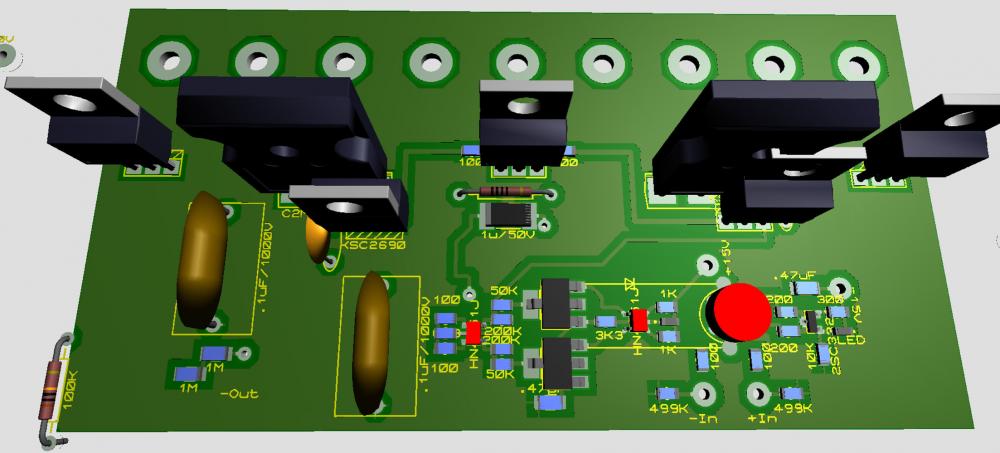

The beauty of making your own boards. Really nice.

-

Great that you got a more stable driver by removing the servo. After a closer look at what you have done I think the servo needs to be further modified to work. My experience is that the opto servo on the KGSShv Carbon works perfect. I use the same opto servo on my SMD Grounded Grid except I changed pzta06 to a to-126 device and removed the trimmer and its serial resistor and that servo works without any drift – high voltage 400, 450 or 500 volts, output current 10 – 20 mA still no drift and offset fixed at zero volts. The driver will probably work as you have it now. Let it get warm and stabilized before turning on the output for the first time for adjusting. One might consider to have the driver on and working while turning on/off the output…

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Maybe I got it all wrong but I think that the modification suggested by Soren, beside onboard feedbacks, is an onboard offset servo. My idea is to have a fixed offset at zero. Then you can concentrate on the outboard (version 2) and its PSUs, preferable with help of a variac. From my experience (very limited though) is if something goes wrong neither zeners nor current limiter will save you from flying black fragments. If you just are looking for some excitement you can try joggling three bottles of nitroglycerine.

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

You can’t get the servo to work? The opto servo on the normal Carbon controls the offset perfect – no drift.

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Just curious. Did you use back to back zeners on the output mosfets suggested by Soren and Kevin? Also what value of the current sense resistors - 5.1 ohms or 12 ohms for "further protection”?

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Very nice! Low voltage +/-18 volts, right?

-

I’m actually a bit surprised that it didn’t explode at +450V. From memory - according simulation I’ve done in LTspice I think it will all explode at +450V and probably even at +15V. The unsuccessful work I’ve done on the Circlotron is with the first generation servo.

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Sorry for your second failure. After my own failures I've been like gun-shy dog – haven’t touched the Circlotron project for a year. But there must be a way to get the Circlotron safe even for the common DIYers, mustn’t it?

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Thanks for the information. I have made some attempts with the Circlotron. Blown both PSUs and outputs. Small black fragments all over the place. Seems that things easily might get wrong and then both PSU and output are effected.

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

@Tinkerer,Sorry for your accident. Did something broke on the output board?

- 256 replies

-

- Circlotron

- High Voltage

-

(and 1 more)

Tagged with:

-

Has anyone tried the low voltage supplies on the HV boards with AMB’s Sigma 78/79 regulators? I think it would be a simple and not very expensive improvement.

-

I run my mini Dynalo at +/-20 volts. AMB voltage regulators, positive 10K and 133K, negative 10k and 160K resistors.

-

https://tubedepot.com/ - Claim they match up to 9 tubes for free??? Also have Philips Miniwatt metal base tubes.

-

Nice! 18.5 mA through output transistors? Nearly 2.5 W each.

-

I had 0.1uF wima in mind, but i'is to low?

-

I guess the 35uF electrolytic are on the board for some reason – why?

-

I'm going to feed ducks, sometime.

-

Brainstorm - Output transistor on bottom side and the other components on the top. There are some 300V and even 400V sot-23 devices.

-

not possible, I am several hours ahead of you Americans