-

Posts

1,541 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Events

Everything posted by JoaMat

-

and now for something completely different part 3

JoaMat replied to kevin gilmore's topic in Do It Yourself

Here is an attempt to make a “smd raal uberamp driver”. I followed Kevin’s schematic. The big resistor is for feedback/gain, I guess 1.5 – 2 W is required and a few components on “solder” side. The real challenge will be the power sections. 3A x * +/-24V * 8 * balanced - might be a bit extreme for headphone amplifier… -

Lately the left channel humming has increased to become even more bloody annoying. But… today I cured it (pure luck - trial and error approach). I have two umbilicals between psu and amplifier. Both carrying 580V bias and then joining at the stax connector. So, I removed left 580V bias wire in amplifier and the hum disappeared. To my ears the amplifier is now dead silent.

-

-

-

Aerial picture of opamp driver and psu. I had some disturbing noise from the Mean Wells. After putting them their own enclosure the noise reduced considerable but there still is audible noise. With AMB’s Sigma22 supply +/-29V the amplifier was noise free. I only tried sigma22 for a few minutes since it hasn’t the current capability as the Mean Well, but it sounded OK. As for sound I find it enjoyable to listen to but I also think it has some sonically drawbacks (maybe) due to the switching mode power supplies. Bottom line is that I agree with the designer

-

Milled a second board today and after some struggling I eventually have a stereo opamp driver. Now I listen to this and this… Grüner Veltliner for my father-in-law... he was born in Austria.

-

I might. Give me a ping.

-

Here is a (my) version of Kevin’s opamp RAAL driver. Board is kitchen made. Some parts are smd but schematic is same as original. Only one channel working and it’s powered by lab power supply max 3A. Occasional when playing, not very load , leds indicating max current hit are flickering. But I've two 340W Mean Well supplies at hand. Mouser don't sell them supplies to ordinary consumers in Europe so my wife bought them for me. Lucky me.

-

-

-

Anyone out there have built the raal opamp driver besides justin? I’m interesting and I guess other people are as well in the outcome and thoughts about the driver.

-

-

-

Kerry Design mini GRHV\GRLV and JoaMat mini T2 Group Buy

JoaMat replied to mwl168's topic in Do It Yourself

B - (((R8+R9+R10)/R7)-1)*Vref -

To me it sounds that you built yourself a nice amplifier. Enjoy.

-

At the power supply schematic – shouldn’t D12 anode be connected to the cathode of D1?

-

If you remove C2 (0.1uF cap) I guess it will possible to set BIAS to 230V with help of the 1M trimmer.

-

Thanks. Who made them - Mueller-r.. something?

-

Nice power supply. I can’t read the labels on trafos. What are their specifications?

-

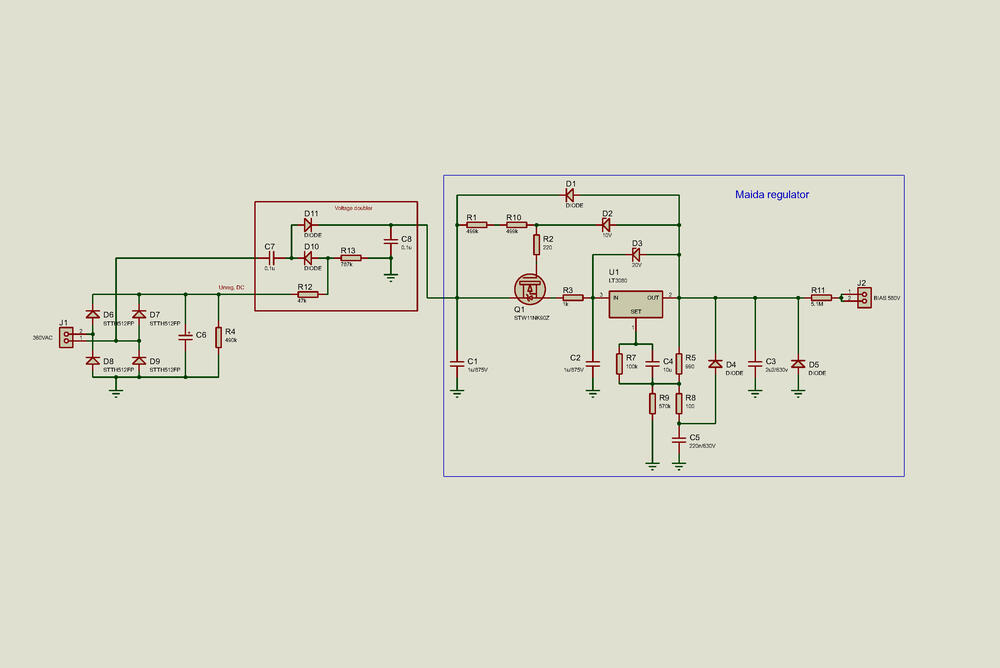

Here is my T2 power supply, now with Pro Bias Maida regulator style. The small board with three blue filter capacitors is the 21st Century Maida Regulator by Tom Christiansen producing 580 volts after change of resistor. The Maida regulator replaces the 10m90s current source with Zener string and filters. I feed the regulator with unregulated 660 VDC. Only 5.1M resistor on psu board is used. Works great. P.S. still need some wire clean up… will probably never happen

-

My condolences, Jose.

-

Tested the 21st Century Maida Regulator as a Bias 580V regulator. Got 558 V with the components I had at hand. It takes about 15 seconds to reach desired voltage. To be continued (maybe).

-

Yes, you are correct. In the 21st Century Maida design R3 and R9 are power resistors. When used for “BIAS 580V” the need for current is about 1 mA, mostly for the voltage divider R5/R9. Highest heat dissipation would be R9, 0.6 W and I’m thinking of two 0.1% thin film resistors here. As for capacitors the C5 (220nF/630V) also needs to be a through hole.

-

Draft of BIAS 580V regulator. Works in LTspice. After the voltage doubler is a Maida regulator. Q1 is a to247 mosfet, C1-3 are 27.5 mm film caps and rest of parts are surface mounted. For Maida regulator see: https://www.ti.com/lit/an/snoa648/snoa648.pdf?ts=1600430373786&ref_url=https%3A%2F%2Fwww.google.com%2F https://www.diyaudio.com/forums/vendor-s-bazaar/209067-21st-century-maida-regulator.html https://neurochrome.com/collections/power-supplies/products/21st-century-maida-http://www.pmillett.com/HV_reg.html

-

Kerry Design mini GRHV\GRLV and JoaMat mini T2 Group Buy

JoaMat replied to mwl168's topic in Do It Yourself

For BOM mini T2 v.22_Date_2020-02-16.xlsx try this: link Please tell if it works. I don't really know what I'm doing. September 20 - Above link to BOM removed as attached files can be downloaded from HeadCase again.