-

Posts

5,478 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Events

Everything posted by Craig Sawyers

-

I know it is FET's rather than tubes, but Erno Borbely used this scheme in many of his products, detailed in "JFETS: THE NEW FRONTIERS,PART 2", Audio Electronics 6/99, 16-20. He did not use cc loads on the top drains, but has a cc load on the long tailed sources. I downloaded it originally from Erno's site, but he has now shut down the business and taken his site down.

-

Sounds like a great day (apart from your sister-in-law's troubles!). Sure beats the hell out of frozen up burst heating pipes, which happened just before Christmas. Bonehead house builder had run unlagged and uninsulated pipes above our entrance porch - so thermally essentially outside. We've been way sub-zero for the last two weeks. When they thawed a little one day when the temperature crept above freezing, water came out of the split pipes under full heating pump pressure - it was a truly impressive sight. Got everything isolated and turned off while phoning the plumber, who got there half an hour later. By then I had pulled the closing panel off, saw the exposed pipes, and was having fantasies about finding the builder and laying about him with a length of two-by-four. The good news is that the burst was *outside* the house, so there was no damage to the house at all. Now properly pipe lagged and joists insulated above and below with high grade lagging. It ain't gonna freeze again.

-

The alternative, used on old Krell power amps (and many high power pro amps) is to have a power resistor in series with the transformer which is shorted out by a relay after a second or two. Various delay circuits are used, either discrete component or 555 based. It has the advantage, as compared with a thermistor, that the impedance in series with the transformer winding is kept to a minimum.

-

Interesting - I was planning on doing precisely the same, having got a ton of Mullard 6DJ8's from an old and sad 535A. They all measure right on the money, so it will be interesting to see if I get a similar noise problem. Perhaps I'm missing something, but it seems a differential pair cascode with constant current loads

-

Kevin - any insight from Stax on this? Is there any indication that they selected 6DJ8's, or that the screening can on the original T2 played a critical role? Now 22:40 in the UK, got a belly full of excellent food and booze - so I'm retiring to a place of horizontal repose.

-

Fantastic news! Is that number 3? KG, Inu and now Blubliss? I'd definitely be #4 if the XXXXing C3675's had arrived before a 4-day holiday. But they didn't, so I'll have to slum it with a BH for a while longer

-

I just love the endless variety on these lists. There is whole musical subset that operate at a level I could only aspire to. I did look at that exercise linked above, and it brought back the grind of learning the clarinet. Mind you, having mastered a bunch of exercises, it never failed to amaze me that a horrible sequence of notes in a real piece would magically just fall under the fingers, with one part of the brain thinking "I wonder where that came from?". Of course it was buried somewhere in an exercise and had got hard wired into the wetware.

-

I'll bet it tastes great though. Here's what I do with regular cheddar - toast some bread. Slice on cheese. Sprinkle with chilli powder (critical step) and put under grill. Cheesy heaven.

-

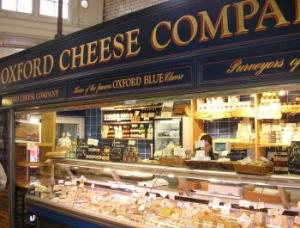

Sounds like a great company do. Wisconsin Cheddar? I buy my cheddar here [ATTACH=CONFIG]4136[/ATTACH] An outstandingly fine non-pasteurised, 18 month matured cheddar called Montgomery. From Yeovil, Somerset Montgomery's Cheddar, world-class unpasteurised, natural cheese made by hand : West Country Farmhouse Cheesemakers : Handmade Westcountry Farmhouse Cheeses .

-

I thought the drive by shooting of effigies of The Stig was pretty good. Interesting that under Tiff Needell's tender care Danny Boyle did a really great lap time in the Reasonably Priced Car. The concept of The Stig had kind of run its course anyway.

-

Yeek! For some reason it made me think of that Soprano's episode when Tony used an industrial staple gun on a guy who'd crossed him...

-

Always look on the bright side of life - it could have happened over Christmas.... Seriously, hope you get over it soon. Food poisoning can be very very nasty. Must have been something badly off (fish? eggs? - or fish eggs?).

-

I will say this only once.... The main actor (played Rene), Gorden Kaye (yes - Gorden, because Equity misspelled his name) was darned near killed is a massive storm in 1990 that cut a swathe through the UK and mainland Europe, with over 100 deaths including Germany and France. Kaye ended up with emergency brain surgery (completely successful) after a chunk of wood was propelled through the windscreen of his car and hit his head. He's still got massive scars on his forehead to prove it. The BBC account of the mayhem of that day his here BBC ON THIS DAY | 25 | 1990: Children killed in devastating storm

-

Ah - the logical opposite of Sgt Pepper, I see....

-

Struts - I know you've answered your own questions, but I thought this might be worth elaborating. The chassis components are all anodized, which is a very good electrical insulator. With such high and lethal voltages I was concerned that isolated chassis components could be a significant hazard. The rear of the mains chassis plug is a case in point. I drew a pencil line around the ouline and then carefully used a dremel with grinding attachment to remove the anodizing behind where the plate mounts. I also dremelled the anodizing off areas when the chassis parts bolt together - the front and back plates where they mount to the heatsinks and top and bottom, the top and bottom where they mount to the heatsinks and front and back plates etc. So now all chassis components are decently electrically bonded. The ground wires in the PSU and amp were fixed with butch star washers to the spare holes in the heatsinks in accordance with safety standards. I might blow the bugger up electrically (and have done) but once it is working and cased up it will be safe

-

Well in my case the C3675's in the battery went short circuit. That massively overloaded the bottom K216 which went short. That massively forward biassed the 100V zeners, which glowed briefly before blowing. The chain of failure also took out D6/D7 by massive overcurrent. Which is why I recommend testing your C3675's for DC current gain (ie *not* small signal slope gain) at 5mA, should be 70-ish or more for good 'uns. 20V is quite enough to test at, and assume that the gain increases by around 10% by 740V (because of the slope in the collector characteristics).

-

I agree. Dead 100V zeners seems to mean dead K216's. Been there, got the badge (root cause for me, crap C3675's). Don't beat yourself up too much about the wiring error - the good news is that one channel survived the trauma. This circuit seems to be a fascinating mix as tough as old boots, and also kind of frail at the same time. Incidentally, got 115 C3675's coming from three different sources now. If all are good, that is a result - plenty for other projects. But three sources hedges my bets - all three lots are unlikely to be simultaneously flakey.

-

Ah. Maybe not. Test D10 and D11. If they are kaput, check the 100V zeners and the K216's on that side.

-

Gate-drain short in Q22? One or all of the 2SA1486's the wrong way round? Wrong values for R33 and R34?

-

That would leave you without a leg to stand on

-

What are the voltages at each end of the batteries with respect to ground?

-

Having just found a wiring error in my Tek 577 curve tracer (which was there since the instrument was built - orange and brown wires were transposed at one point. So Tek could not possibly have calibrated the thing), I can now at last give much more definitive measurements for my transistors. The good 2SC3675 measure a DC beta of between 74 and 90 at 750V and 5mA. Which is why the battery should work with good parts. This matches quite well with KG's base current measurement of 50uA on his prototype battery. The duff 2SC3675 measure a DC beta of between 9 and 11, but you cannot get close to 750V. The curves turn upwards on a fast power law over 550V. I have no idea what crap piece of random silicon is in the packages, but the correct one it isn't. Which is why they die, catestrophically in the T2, with serious collateral damage. The 2SC4686A measure between 30 and 34 at 750V and 5mA, and are probably too low to work properly in the T2 batteries without some mods. According to the spec sheet these transistors can have a beta of up to 60 at 3mA and 5V, but none of my batch do this (and neither did Inu's).

-

Way to go! Crutches will come easy with a bit of practice, don't worry. Broke my foot around 10 years ago while cross country running, and was given crutches. I was working in London at the time. Big advantage on a crowded commuter train was that I got to use the disabled seat! But using the underground (tube) was a bit of a hairy experience - I was willing everyone to keep clear of my foot - I would not have been accountable for my actions if anyone had stood on it.

-

Holy crap. Is there a dog somewhere in that pincushion?

-

Mine in more into rodents. Payed off big time when she started chewing up rats - turned out there was a nest under one of our sheds. Cat would come in strutting her stuff with a scratched up face (rats really put up a fight) having eaten most of each rat.