-

Posts

4,908 -

Joined

-

Days Won

79

Content Type

Profiles

Forums

Events

Everything posted by dsavitsk

-

Happy Birthday, Chris!

-

Does anyone have a suggestion on finding a top loading, internal, sata, dvd rom or burner that could be used in a custom computer case? There are plenty of external dvd burners, but I am not sure how easy it would be to incorporate one into a different case. Thoughts?

-

My wife left her Incredible on the train. Any suggestion of an Android phone that can be had for not too much money that will work with Verizon. Does not need to be bleeding edge, just good enough to work in a pinch.

-

Happy Birthday!

-

Interesting. It looks like the precision of 0805 resistance is up to 1% in the simulation.

-

Happy Birthday!

-

Nope.* I also regularly see RCN trucks on our street, and there is a billboard a block away, but we can't get that either. We used to have regular AT&T DSL, but it was a little too slow in the end. * edit: Er, maybe. In keeping with AT&T's standard level of competence, going through the website differently, it might be available.

-

Fwiw, and to offer a counter to this, I absolutely hate the SB (here's my last rant on the subject from a while back http://forums.slimdevices.com/showthread.php?t=60755 so maybe things have changed). I hate it so much I can't even make coherent posts about how much I don't like it. Well, what I can't stand is the squeezebox server. To be sure, there is a certain segment for whom I am sure it works great. If you just want to click an album and play it, then it is great. But, if you are like me, have a large music collection full of stuff you have forgotten about, and like to accidentally discover stuff, then it is really miserable. An example -- in Winamp, I can type "my" into the search box and instantly see that I have music from Emmylou Harris and "Mark Knopfler and Emmylou Harris", plus a bunch of other stuff like "My World 2.0 by Justin Bieber" (that's a joke). But, I can ctrl+click on just those two that I am interested in, quickly see a list of the tracks, and queue up what I want by dragging and dropping. In SBS, you'd have to brows to "e" in artists, click on Ms. Harris, click on a particular album, then individually click tracks to add them. If you then wanted to get the other album, you'd have to go to "m" and do the same thing. Then, if you wanted to reorder your queue, you have to do it slowly track by track. Maybe this works if you run SBS on a quadcore i7, but I don't. Indeed, I don't run it on anything anymore because I can't stand the process of using it. Maybe the android control, or Moose makes this a little better, but it is still a pain. Though, this looks promising http://www.thejavashop.net/bjj/index.shtml, thoug it looks better for MPD than SBS. Edit: maybe this is the core of the issue for me http://forums.slimdevices.com/showpost.php?p=403964&postcount=43

-

There were a couple of winamp controllers, but Winamp sent them cease and desist letters for trademark infringement. I guess one is back up (aWARemote). Possibly an option, but the requirement to run windows on a basically headless computer and to keep winamp running all the time is aggravating. Digging around, finding a way to do seamless remote windows is really tricky. Citrix has a solution, but it is expensive. Windows server 2008 can do it (via RDP 6), but again, it is expensive. RDP is the way that you can run seamless applications under a windows virtual machine on windows 7, but it does not look like you can do it across a network w/o the server version. There is a version of VNC that can, but it is only windows, and would require being logged in on the remote computer. There is also NX or NeatX but probably no Android client (even though the latter is a Google product) as you still need X11. But, I think there may be a good solution in MPD. There are a couple of Android clients out there, or I may dust off Eclipse and write my own. But, it looks like it could run on a headless BSD box w/o X installed.

-

Happy Birthday!

-

Gambling is for people who don't understand mathematics. I really dislike Comcast for all sorts of reasons, but it is kind of the only game in town in Chicago. AT&T is a pain for internet, and I tried Clear, but I could not get a good enough signal. Maybe Verizon will build a new 4G antenna nearer me that will work better. The biggest issue with Comcast is that their DVRs are just terrible.

-

http://www.nytimes.com/2011/04/27/arts/music/poly-styrene-brash-frontwoman-of-x-ray-spex-dies-at-53.html?_r=1&hpw “Poly Styrene’s voice on ‘Oh Bondage! Up Yours!’ was the most exhilarating voice I ever heard — it was all body,” said Kim Gordon of Sonic Youth.

-

Happy Birthday, Ryan!

-

http://www.nytimes.com/2011/04/27/arts/music/phoebe-snow-bluesy-singer-songwriter-dies-at-58.html?_r=1&hp http://www.chicagotribune.com/entertainment/la-me-phoebe-snow-20110427,0,1871879.story

-

Poor pups

-

It appears that someone cut and pasted a different web page and just didn't edit a few of the values. That stuff is clearly from a power amp page. Anyway, I don't see any untold riches to be found here, but to each his own.

-

12AX7 cathode followers are worthless, even paralleled. They just don't have enough current across them or Gm to drive anything. Generally, for lowest distortion, a tube wants to see a load several times higher than its rp (even when the load is on the cathode). rp on an AX7 is ~80K, both sides ||, 40K. That means that if your next stage has an input Z of lower than 250K, distortion will be high. Maybe it will sound toobey. What's with the Ultra Linear class AB, 1W into 8 ohms, and the 240W power requirement? Just a sloppy cut and paste job?

-

Looks like I mistyped -- I meant that I wanted an android device to be an X terminal, a thin client that does the display part of programs running on the terminal server. So, not an "Xterm". So, what I really want is an interface on a tablet that looks like the Winamp media library and play list that controls the actual application running on the FreeBSD box across the room. RDP and VNC are both cumbersome ways to accomplish this, but it seems like making X do what X was designed to do in the first place should not be so hard ...

-

I am generally opposed to anything Apple (though I do enjoy Olympic Decathlon on the old ][+), but if that works, I could definitely see having an iPad as a Xterm to control a FreeBDS box. I'd prefer an Android, though. VNC is worse than RDP.

-

Used to be that Apple was a hardware company that created an OS to sell the physical units. Now, Apple is actually a memory company that makes all sorts of loss leading products to sell it. One question -- anyone have any insight into running Xterm on an Android tablet? I was thinking that a *BSD music server/player with a remote interface would be just the sort of music system I have been looking for, and not finding, for years. Best I've come up with is an RDP client on a laptop to control an XP box, but it's not ideal and is way too cumbersome ... and I hate the squeezeserver, so that has ceased to be an option.

-

An orange, and a banana, and a chocolate chip cookie dipped in ganache.

-

I was thinking that you were zeroing offset between the two plates, in which case R7 would need to be in a different place. But, yes, as you have it, you can zero it w/r/t/ ground, though you can't do it for both sides. But, why does that matter? The headphones appear to be differential, don't connect to ground, and thus have no zero reference? Instead, they just need to sit some voltage below the bias. So, you'd either simply increase the bias to some voltage above the plates, or you could tie the B+ to ground and consider it a negative rail only. Something like the LL1668 as a plate choke will drop ~7V in this setup, which seems pretty incidental, and will keep the offset from bias pretty close to what you want.

-

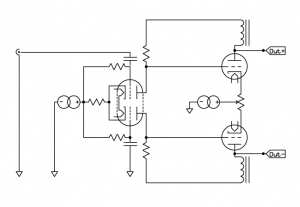

As someone who has never built a stat amp, here's my contribution Basically, LTP input and output stages. Choke loads on the output, and while chokes are not free, I think the savings of not needing a bipolar supply would make up for it.

-

I think R7 is out of place, too. Have you compared the driver + cathodyne to just using the first tube as a LTP splitter? I don't have enough experience with either topology to form much of an opinion so I am curious if you tried both. One thought, though, is that LTP front end might enable DC coupling and eliminating the negative rail (to keep the cathode load high (though, does it really matter?), use a choke, or use a single CCS bypassed by a high value resistor to give some slop)?