Leaderboard

Popular Content

Showing content with the highest reputation on 09/22/2024 in all areas

-

4 points

-

2 points

-

2 points

-

1 point

-

1 point

-

oops In my day job I usually lecture to 18+ audience and if no one gives me a limitation on detail I tend to go for high levels of detail because in reality its almost never as simple as X is better than Y, it's almost always the case X and Y offer different compromises and its (in my opinion) important to understand what is going on and understand the compromises.1 point

-

1 point

-

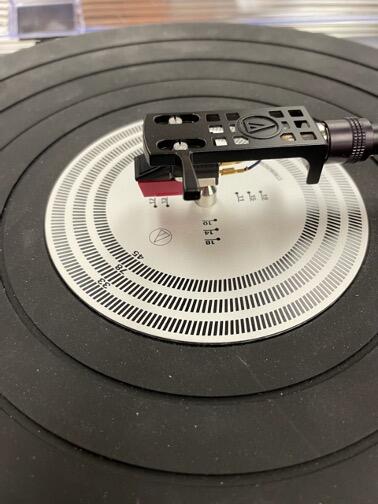

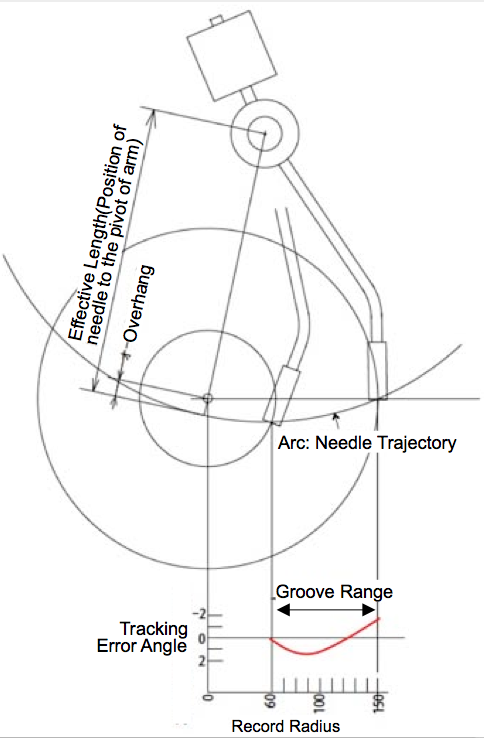

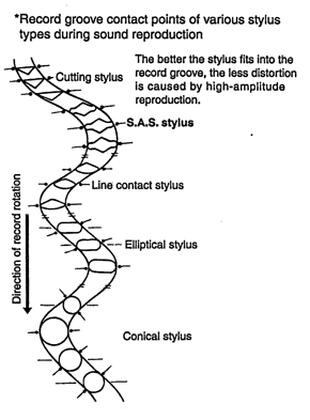

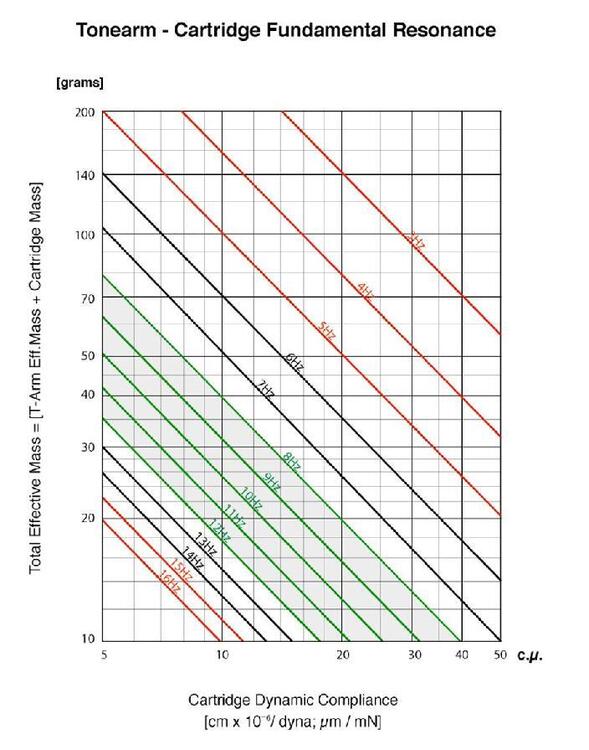

Ok i will open the can of worms. Please note I have had to make a LOT of generalisations here: records are cut with a linear tracking arm and ideally should be played back the same way so the play back diamond is aligned with the cutting diamond. In reality quality linear tracking arms are not easy to engineer and tend to be expensive and so arms that track in an semi-circular arc often used because they can be easier and cheaper to make. But this introduces errors between the alignment of the cutting diamond and the semi circular arc of the playback. you would expect the semi corcular playback arc to only align with the cutting arm at one point. But by some clever geometry it is possible to align two points and reduce the tracking error. If the two zero error points are too close together you get more distortion at the beginning and end of a record then optimal and less distortion in the middle of the record. If the two zero points are too far apart you get lower distortion and the beginning and end but more distortion in the middle. Given different records have different amounts of the record with music on there has always been arguments about the exact placement of the two zero tracking points. Unfortunately to do this trick it requires the cartridge to be skewed compared to the pivot in the arm AND requires the cartridge to overhang the centre point of the record by an amount. This is made more complicated because not all arms have the same pivot to cartridge mounting hole distance and not all cartridges have the same distance from diamond to the mounting holes either. The result is that the diamond to arm pivot distance is not standardised at all. As a result the cartridge has to be moved forward or back in the headshell and/or the base of the arm moved to get the correct overhand from the diamond to the centre of the record. There are various ways of attempting to make this alignment, Some rely on the cartridge being exactly parallel to the headshell and assume the headshell is correctly angled and then slide the arm base or cartridge back and forth until the diamond overgangs the centre spindle by the correct ammount Others methods assume the overhang is correct and have parallel lines at the two zero tracking error points and ask you to adjust the angle of the cartridge in the headshell to be parallel to the lines. A few advanced (and generally expensive) alignment tools actually allow both overhang and angle to be set. However, all this assumes that the diamond is at 90 degrees to the cantilever and the cantilever is parallel to the cartridge etc. In theory proper alignment would be done looking at the diamond rather than the cartridge body. another issue is that the suspension on the cartridge acts like a spring and will resonate at a certain frequency, the higher the mass of the arm + cartridge the lower the resonance frequency. The more stiff the suspension the higher the resonance frequency. If the resonance frequency is too low i.e. the mass of the arm and cart too high and the suspension of the cart too soft then the resonance can be excited by record warps and the suspension can resonate like crazy and even bounce the stylus out of the grove! If the suspension of the cart is too stiff and the mass of the arm and cart to low the resonance frequency can be so high low frequencies in the groves can excite the resonance and cause the suspension to go crazy. This is another reason low mass carts usually have soft suspension and high mass carts usually have stiff suspension. This means some arm and cartridge weight combinations simply will not work well. There are online calculators where you can enter the moving mass of the arm, the mass of the cart and its suspension stiffness and get out the resonance frequency. Similarly some cartridge mounting hole to diamond lengths are outside the adjustment range of some arms or headshells and so it's impossible to get them reasonably aligned - when you decide what reasonably aligned is. Similarly some carts are too light or too heavy for the arm to balance correctly and you either have to add weights to the headshell in the case of too light weight which has the side effect of changing the moving mass and therefore the resonance frequency or add mass to the back of the arm if the cart is too heavy (which will also change the resonance frequency) In other words there are a whole set of interrelated compromises and assumptions about cart mass and suspension stiffness and diamond to mounting hole distance. MC vs MM moving coils generally have a much lower output voltage than moving magnet but a much lower output impedance. A quality step up transformer designed for the job into a mm preamp input is certainly an option. In my experience step up transformers are sensitive to external magnetic fields so try to keep it away from power supply transformers, mains wiring etc. Your Denon MC has 0.25mV and MM carts somewhere around 2mV. So about a x10 step-up or 20dB gain. Generally dedicated Mc preamps will boost to line level ~1.5V or around x1000 or 80dB gain and do the RIAA equalisation and feed into a line level input on the preamp. Low noise MC preamps are a bit of a challenge given the gain they have to do. In general dedicated MC preamps have multiple resistance loading options, many have multiple gain options and some even have capacitance options to. i.e. more scope for tweaking the sound. Is it worth going MC? much more difficult question to answer In general MC are better sounding than MM for a variety of reasons. MM are usually the lower cost option and more design and precision goes into the MC carts which are perceived as the premium cost option. In general MC have lower moving mass because the diamond is attached to a cantilever which is attached to some lightweight coils and the magnets can be relatively large and fixed to the cart body. MM can have lots of coils fixed to the cart body but the magnet is attached to the cantilever and is generally quite high mass. Its that mass the diamond is trying to move when it reads the record grove. MCs generally have better profiled diamonds too which can read more of the fine wiggles in the grove than a cheap profile like a spherical diamond. better diamond profiles will also reduce record wear because the tracking weight is distributed over a taller slice of the grove. MM carts are usually lower mass and so can have a more compliant and soft suspension which in general helps with low frequency tracking performance, but generally have less refined diamond profiles resulting in poorer high frequency tracking but as a result are cheaper to manufacture. MCs usually have better diamond profiles and this helps with high frequency tracking performance but are heavier and so have less compliant suspension and poorer low frequency tracking and since making diamond profiles is precision engineering this makes MC carts more expensive. Because of the higher stiffness/lower compliance of the suspension of the MC cartridge they generally require higher tracking weights to keep them in the grove, conversely MM carts usually require less weight. MM around 1.5Grams MC around 2.5grams. Too little tracking weight and the diamond stops following the grove properly and as well as creating more distortion this can damage the record. So there is a tradeoff too high tracking force and you add to diamond wear and record wear, too little tracking force and your diamond starts to cut its own path through the record groove. Against all of this you have to bear in mind if you wear out the diamond or damage the cantilever, many MM carts have user replicable diamond and cantilever and the diamond profiles are usually cheaper so the running costs are lower and you can keep a spare stylus around for a quick swap out if needed. Some MMs even have a range of available diamond profiles so you can upgrade the performance by replacing the diamond/ cantilever with a higher end one e.g. ortofon om series MM carts. Very few MC carts have user replaceable diamond/cantilevers and so almost all require a rebuild if damaged or the diamond is worn - so the running costs of MC carts are generally higher, in many cases a single rebuild of a MC can be a significant percentage of the cost of simply buying the cartridge again. ( I hope this is not too rambly for you) 😁 please note I have had to make a LOT of generalisations here. There are some high end expensive MM carts with nice diamond profiles and some low end MCs with plastic bodies, low weight and with crappy diamonds (e.g. ortofon mc10 super). Some MC carts can have a high output voltage and some MMs can have a low output voltage (e.g. some grado MMs). etc etc.1 point

-

Advice requested: I'd like to try an MC cartridge on my Technics SL1700 (it's very much like the SL1200). Namely a Denon 103R anniversary edition: 1. I don't really understand cartridge/tonearm matching, but I've read about an overhang issue with the Technics tonearm. Is that a thing (and can someone explain it to me like a 4y/o please)? 2. Can I run it with a SUT & my existing MM-only preamp? Or is it preferrable to get a dedicated MC preamp? Which is the better way to go? 3. Is it worth it?1 point

-

1 point

-

1 point

-

1 point